Gear Industry News January 17, 2023

[please visit our sponsor]

AGMA Updates

Bevel Gear Systems Design

February 7–9, 2023; February 14–16—online course

Learn how to design and apply bevel gears systems from the initial concept through manufacturing and quality control and on to assembly, installation, and maintenance. Engage in a practical hands-on guide to the bevel gear design, manufacture, quality control, assembly, installation rating, lubrication, and application.Register Today

Gearbox CSI

February 28–March 2—Hilton Philadelphia at Penn’s Landing

In this course, we will define and explain the nature of many gear and bearing failures and we will also discuss and describe various actual failure scenarios. In addition, a detailed primer on bearing technology prefaces the failure scenario discussions. You will gain a better understanding of various types of gears and bearings. Learn about the limitation and capabilities of rolling element bearings and the gears that they support. Grasp an understanding of how to properly apply the best gear-bearing combination to any gearbox from simple to complex.Register Today

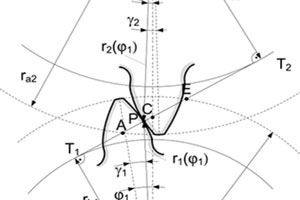

Loaded Tooth Contact Analysis

March 7—online course

Evaluation of loaded tooth contact and development of tooth modifications using commercially available software to improve Khb and optimize power density. Two real-life gearing examples will be presented in the course, one will have a cantilever-mounted pinion, the other a shaft pinion straddled non-symmetrically by bearings. Both examples demonstrate component deflections under load which significantly reduce tooth mesh contact which is then corrected with developed helix and profile modifications.Register Today

Epicyclic Gear Systems

March 28-30—Marriott Clearwater, St. Petersburg, FL

Learn and define the concept of epicyclic gearing is including some basic history and the differences among simple planetary gear systems, compound planetary gear systems and star drive gear systems. Cover concepts on the arrangement of the individual components including the carrier, sun, planet, ring and star gears and the rigid requirements for the system to perform properly. Critical factors such as load sharing among the planet or star gears, sequential loading, equal planet/star spacing, relations among the numbers of teeth on each element, calculation of the maximum and optimum number of planet/star gears for a specific system will be covered. Provides an in-depth discussion of the methodology by which noise and vibration may be optimized for such systems and load sharing guidelines for planet load sharing.Register Today

[please visit our sponsor]

Industry News

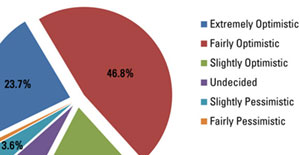

Your Voice Counts!

Take Part in our Annual Survey

Gear Technology's annual State-of-the-Gear-Industry Survey is a valuable resource for the entire industry, helping us better understand the current economic position and outlook for companies manufacturing gears. The survey takes less than 10 minutes and results will be available in the January/February 2023 issue.Take the Survey

Auto Gear Joins Gear Motions

Gear Technology

Gear Motions is proud to announce that Auto Gear Inc. has joined the Gear Motions family. Auto Gear, located in Syracuse, New York, specializes in efficient and economical low-volume gearbox production, from design to delivery.Read More

Interact Analysis Sees Geared Products Market Growth in 2022

Power Transmission Engineering

Updated research from Interact Analysis shows the geared motors and industrial gears market experienced strong growth in 2021. The market expanded by 16 percent last year, with the sharp rise driven by price increases. On average, the selling price for geared motors and gearboxes increased by 7.8 percent in 2021, with further price rises forecast in 2022.Read More

|  |

The whack-a-mole economy: U.S. manufacturers struggle with unpredictable supplies

Reuters

Glen Calder expected a shipment of gearbox reducers needed to build a particular model of his company's paving machines last week. But when he called on Thursday to check the status of the order, he learned the shipment—coming from Italy—is now delayed three months.Read More

Manufacturing in Minutes: The 3D Printing Revolution

Reliable Plant

As consumer demand increases in complexity, for facilities to find success, they must keep an eye on new technologies and trends that offer solutions to complex problems. One technology ushering the industry into a new age is 3D printing.Learn More

The Best Cars, Rides, and Auto Tech of CES 2023

Wired

Proof, if it were needed, of just how much of CES has become an auto show landed at the 2023 opening keynote, which was hosted by BMW and featured its color-changing i Vision Dee concept. Sidekicks wheeled out onto the stage included Herbie, KITT, and, yes, Arnold Schwarzenegger.Read More

New 18-MW Model Takes Over as World’s Largest Offshore Wind Turbine

Power

A subsidiary of the China State Shipbuilding Corp. (CSSC) has unveiled components for what would be the world’s largest and most-powerful wind turbine, an 18-MW product that tops the recent launching of a 16-MW turbine developed by other Chinese companies.Learn More

AI Enables What’s Next in Manufacturing

SME

From cost savings and revenue growth to end-to-end visibility of manufacturing operations and waste reduction, the use of artificial intelligence (AI) tools is vital for manufacturers to stay competitive.Read More

For ‘Guillermo del Toro’s Pinocchio,’ a Star Built From Tiny Gears and 3-D Printing

The New York Times

The studio behind stop-motion hits like ‘Corpse Bride’ and ‘Fantastic Mr. Fox’ started work on the new film in 2008 but had to wait for the technology to catch up.Read More