[please visit our sponsor]

Detailed Gear Design

April 16–19—The Westin Arlington; Arlington, VA

There is a distinct difference between “designing” a gear and “optimizing” a gear design. In this course, we will address the optimization process via an understanding of those factors beyond basic banding and pitting ratings. Optimization may focus on load capacity, economy of production or minimization of overall gear system envelope. In this course we will learn how to improve gear designs via optimization and gain new insight into concepts presented through illustrations and demonstrations. Explore all factors that go into good gear design from life cycle, load, torque, tooth, optimization, and evaluating consequences.Register Today

Integration and Trade-offs in Gear and Bearing Systems

April 23–24—The Graduate Hotel; Ann Arbor, MI

The purpose will be to cover the concurrent design and analyses of gears and bearings in integrated systems like gearboxes, transmissions, and electric motor drives, so as to allow for good integration and faster optimization of the overall system. This will help gear engineers and suppliers better determine the trade-offs with the bearings, help bearing engineers and suppliers similarly with the gears, and system engineers better understand both. The examples covered are generic but should be useful both within and across industries that use these components and systems.Register Today

EV Automotive Transmission System Design

April 23–25—The Graduate Hotel; Ann Arbor, MI

This course will cover all aspects of gearbox concept, development, design, and through the initial stages of analysis as related to product requirements. We will review all the most common EV transaxle architectures, power flow and layout and the ‘whys’ of packaging as such. Independent of the architecture and/or layout, there are many similarities in the functional and operational requirements of an EV transaxle gearbox. We will work through all of those and develop a workable set of requirements that will then be used as the design basis. From a high-level point of view the ‘Big’ difference between transaxles for EVs (Electric Vehicles) and transmissions designed for more traditional Manual Transmissions (MTs) and / or Automatic Transmissions (ATs) is the lack of the ‘noisy’ internal combustion engine or ICE motor.Register Today

Gear Manufacturing and Inspection

May 7–9—Sheraton Suites Wilmington Downtown, Wilmington

While function and rating are important factors in a successful gear design, to be truly optimal and successful, the gear designer must also design the gears to be manufactured and inspected. In this course, therefore, we will address key factors in a wide variety of manufacturing and inspection processes to enable the gear designer to better design optimal gears considering both rating and the necessary manufacturing and inspection processes to produce the gears as designed.Register Today

[please visit our sponsor]

With the WORM drives, everything is high efficiency

Worm drives, the most compact gear system; provide high-ratio speed reduction and greatly increase torque. To be effective, it’s crucial that they are manufactured with high-quality standards to ensure all requirements are precisely met. CHUN YEH GEAR can manufacture - Max. Module: M10, Accuracy Capability: DIN 1, AGMA 14, JIS 0.

Read More

Gates Launches Clean Master Plus

Gates announces the launch of the Clean Master Plus hose platform, the newest addition to Gates’ industrial hose lineup, built for high pressure applications in demanding industrial environments.

Read More

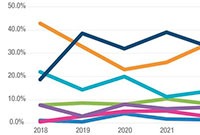

2024 State of the Gear Industry

Gear Technology’s annual State-of-the-Gear-Industry survey polls gear manufacturers about the latest trends and opinions relating to the overall health of the gear industry. As in years past, the survey was conducted anonymously, with invitations sent by email to our subscribers, AGMA members and others in the gear industry.

Read More

Motion Agrees to Purchase Two Fluid Power Companies

Power Transmission Engineering

Motion Industries, Inc. has signed a definitive purchase agreement to acquire the operating assets of Perfetto Manufacturing and SER Hydraulics. Subject to customary closing conditions, the transaction is expected to be finalized at the end of February.Read More

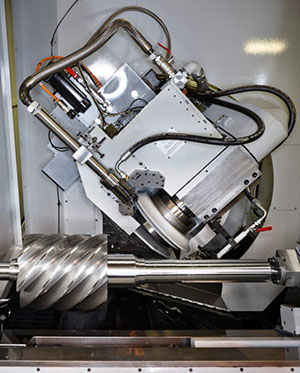

Next Level Control for PTG Holroyd’s Helical Rotor and Thread Grinding Machines

Gear Technology

UK-based PTG Holroyd has announced that going forward, all models in its TG Series of ultra-precise helical rotor and thread grinding machines will be equipped with the Siemens digitally native Sinumerik One CNC as standard. PTG Holroyd was the first UK machine tool manufacturer to embrace the benefits of the Sinumerik One CNC, incorporating the control system into its recently launched HG350 range of worm and gear grinding centers.Read More

Gearbox Maker Flender Secures Wind, Solar Power for German Ops

Renewables Now

German mechanical drive systems producer Flender has signed wind and solar power off-take agreements with electricity contractor ECO2GROW which enable it to cover 12% of its energy needs at home. One of the power purchase agreements (PPA) relates to a wind farm equipped with Flender’s gearboxes.Read More

|  |

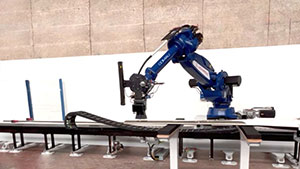

Kawasaki Robotics Partners with Olis Robotics to Offer Remote Robot Monitoring, Control

The Fabricator

Olis Robotics and Kawasaki Robotics Inc. have partnered to make Olis remote monitoring and error recovery software available for any Kawasaki robot model starting in Q2 2024. According to the companies, this offering will help users restart production quickly, reduce troubleshooting and downtime costs, and gain access to support quickly.Read More

Making Laboratory Automation Work: Considerations for Success

MedTalk News

With the potential to boost productivity by up to 90% while reducing cost per specimen, laboratory automation is reshaping medical research. Finding new compounds for novel medicines and materials is traditionally not an easy process. It could require hours of complex synthesis steps, analysis and trial and error before the desired compound is formed. But the rise of autonomous laboratories could transform the way we discover and manufacture these novel compounds.Read More

IKO Linear Motion Rolling Guides Address Battery Manufacturing Challenges

Power Transmission Engineering

As new electric vehicle (EV) advancements drive investments in an automated production infrastructure, there are aspects of EV manufacturing in which specifying an appropriate motion component requires particularly careful consideration. That’s because the heart of the EV — the lithium-ion (Li-ion) battery — poses safety and performance risks that you must keep in mind when selecting motion components.Read More

|  |

IIoT and its Cybersecurity Implications

Manufacturing.net

In addition to enhancing automation, the Industrial Internet of Things (IIoT) has eased convergence and collaboration between Information Technology (IT) and Operational Technology (OT) teams. It has revolutionized manufacturing by cutting costs, improving visibility through real-time insights, and heightening operational efficiency. However, because IIoT devices are interconnected through the internet (directly or by proxy), they can be vulnerable to remote cyberattacks.Read More

Comau and Leonardo Partner on Automated Inspection Solution

Aerospace Manufacturing

The increasing push for faster processes, better control and higher quality in the aerospace industry necessitates a new generation of advanced automation designed to automate complex processes that until a short time ago could only be done manually. When it comes to testing critical structures such as helicopter blades, for example, the potential benefits of automation increase exponentially, as robotic inspection grants accuracy as well as efficiency.Read More

Production Process, Digitalization Technologies Drive E-Mobility Solutions

CompositesWorld

Dieffenbacher (Eppingen, Germany) welcomes composites manufacturers who are eager to help their customers in the automotive, aerospace and sports and leisure industries seize e-mobility opportunities. The company’s manufacturing technologies and plants support the production of a variety of mobility solutions, ranging from automotive parts to emerging applications like transportation, passenger drones, electric surfboards, and jet skis.Read More

|  |