[please visit our sponsor]

Ring Gear Repaired with Dievar Material by Laser-Powder Direct Energy Deposition (LP-DED)

February 5, 1:00–2:00 PM (EST)—Free Emerging Tech Webinar

Laser-powder directed energy deposition (LP-DED) reduces lead times and offers potential benefits for the gear industry, but more research is needed on the performance of DED-manufactured and repaired gears for widespread adoption.Register Now

Gearbox CSI: Forensic Analysis of Gear & Bearing Failures—Useful Tools for Optimizing Gear Design

February 25–27—Kimpton Hotel Monaco; Philadelphia

A good understanding of individual failure modes and the failure scenarios that led to the actual system failure is an essential skill to designing gear/bearing systems that will operate properly for their full design life. In this course, we will define and explain the nature of many gear and bearing failures and we will also discuss and describe various actual failure scenarios.Register Now

A Practical Approach to Managing Gear Noise

March 4—Live Online Course

This course combines light theory with a heathy dose of practical testing and simulation techniques used to manage gear noise. Topics focus on insights into the mechanisms for both whine and rattle, the two most common categories of gear “noise.”Register Now

Epicyclic Gear Systems Design

March 18–20 & March 25–27—Live Online Course

Learn and define the concept of epicyclic gearing, including some basic history and the differences among simple planetary gear systems, compound planetary gear systems and star drive gear systems. Provides an in-depth discussion of the methodology by which noise and vibration may be optimized for such systems and load sharing guidelines for planet load sharing.Register Now

Basic Training for Gear Manufacturing

April 7-11—AGMA National Training Center; Chicago

Learn the fundamentals of gear manufacturing in this hands-on course. Gain an understanding of gearing and nomenclature, principles of inspection, gear manufacturing methods, and hobbing and shaping. Utilizing manual machines, develop a deeper breadth of perspective and understanding of the process and physics of making a gear as well as the ability to apply this knowledge in working with CNC equipment commonly in use.Register Now

[please visit our sponsor]

Save Big on Fine Pitch Gear Production

You’ll pay a premium for the ‘household’ brandnames – and fine pitch gear production doesn’t come cheap. Machine Tool Builders has brought economical, worldclass performance to fine- and super-fine pitch gear production with HAMAI horizontal hobbing, SMG vertical hobbing, and Burri combination profile and generating grinding machines. Various capacities, automation and other options to choose from.

Contact MTB Today

2025 Courses Now Open for Registration!

The schedule of AGMA classes for 2025 is now available, and registration is open! Earn continuing education units in one of our IACET-accredited courses while also learning from industry experts and networking with your peers.

Register Today

Food and Beverage Customer Tackles Operational Challenges with Dodge OPTIFY

In the fast-paced world of industrial operations, efficiency and cost savings are paramount. Enter OPTIFY, the complete portfolio of cutting-edge Industrial Internet of Things (IIoT) solutions from Dodge, designed to revolutionize how global manufacturers manage their operations.

Read More

Index Corporation Announces Reorganization and Team Additions

Gear Technology

Index Corporation has announced that Michael Huggett will succeed Cris Taylor as the company’s President & CEO. Index has also announced a restructuring of its sales team that includes the addition of three new members and reorganization of its territories. Bryan Young has joined the company as National Sales Manager, while John Kemezis and Jason Shorette have joined as Regional Sales Representatives.Read More

Luftex gearbox repair facility gets $3.5 million grant for new Lufkin office building

KETK

The Angelina County Commissioner’s Court has approved an Economic Development Grant for a new $3.5 million office building at the Luftex industrial gearbox repair facility in Lufkin. They clarified that the six-year grant agreement is not a tax abatement and that the new construction will bring additional jobs to Angelina County. The new office building will also include a training facility for new hires and quarterly customer trainings.Read More

Machine Learning Boosts Wind Turbine Efficiency with Smart Failure Detection and Strategic Placement

Scientific Reports

An essential component of the turbine’s power-generating system, the gearbox effectively transfers rotational energy from the blades to the generator. The gearbox is engineered to endure elevated loads and fluctuating wind patterns, guaranteeing the turbine’s maximum efficiency and durability. It transforms the low-speed, high-torque revolution of the blades into high-speed rotation appropriate for producing energy by an elaborate gearing mechanism.Read More

|  |

79th STLE Annual Meeting & Exhibition

Gear Technology

Each year STLE's conference showcases some 500 technical presentations, application-based case studies, best practice reports and discussion panels on technical and market trends. The exhibition and popular Commercial Marketing Forum spotlight the latest products and services of interest to lubrication professionals that come from around the world, representing a full range of the industry’s most prestigious corporate, government and academic institutions.Read More

How to Turn Gearbox Contamination Control into a Competitive Advantage

Precision Lubrication

At any given point, the overall contamination in a gearbox is B.I.G.! Remember that contamination ingression is the overall amount of contaminant in the oil with: B—Built-in contamination from the unit’s manufacture. I—Ingested is the “sucked in” contamination during operation, whether as the unit cools or other activity such as top-ups and oil changes. G—Generated during operation, or in other words, wear and fatigue creating debris, whether from the lubricant, ingested contamination, or other root causes.Read More

Oakland University Launches Mechatronics and Robotics Degree

PTE

Oakland University launched a new undergraduate engineering program—the Bachelor of Science in Mechatronics and Robotics Engineering—uniquely crafted to meet the surging demand for professionals who can bridge the gap between mechanical engineering, electrical engineering, computer science and controls to design and build intelligent systems.Read More

|  |

Germany Wakes Up the World from the Hydrogen Dream

EcoNews

German automotive innovation remains at the forefront while its newest breakthrough enhances electric vehicle (EV) technology development. By investing in DeepDrive’s transformative electric motor technology, BMW shifts its automotive movement towards sustainable electric motors instead of hydrogen fuel cells. This article examines the development of this breakthrough technology, which will shape the mobility systems of tomorrow.Read More

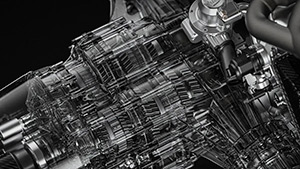

Koenigsegg’s 2,300-hp Hybrid Beast Gets “Light Speed” Transmission

Interesting Engineering

Koenigsegg is currently in the final stages of developing the Gemera hypercar, with pre-production models being assembled at their facility in Sweden. The company recently revealed details about the car’s unique transmission system, dubbed the Light Speed Tourbillon Transmission (LSTT). This complex nine-gear system is designed to manage the power output from Gemera’s hybrid powertrain, which combines a powerful V8 engine with an electric motor. While the company claims the LSTT will offer lightning-fast gear changes and exceptional efficiency, its real-world performance remains to be seen.Read More