[please visit our sponsor]

2023 Emerging Technology Webinar Series

April 5—online

In “Maximizing Manufacturing Efficiency: Using Additive Manufacturing to Consolidate Parts and Enhance Functionality,” Alastair Crowe, director of engineering, 3DEO, will explore how 3D printing can help manufacturers achieve greater efficiency and improved component functionality. Specifically, we will focus on how additive manufacturing (AM) can be used to consolidate multiple parts into a single component, reducing assembly time and costs while still allowing for complex geometries.Register Today

Basic Training for Gear Manufacturing—Spring

April 17–21—AGMA National Training Center, Chicago

Learn the fundamentals of gear manufacturing in this hands-on course. Gain an understanding of gearing and nomenclature, principles of inspection, gear manufacturing methods, and hobbing and shaping. Utilizing manual machines, develop a deeper breadth of perspective and understanding of the process and physics of making a gear as well as the ability to apply this knowledge in working with CNC equipment commonly in use.Register Today

Reverse Engineering

April 25–26—online

Reverse engineering a gear system is a not too unusual task and in many, but not all, cases the process goes fairly well, thus it is easy to become complacent. It is important, however, to fully understand the process and the best practice procedure for reverse engineering a gear system. Failure to fully follow best practice can result, at best, in an unhappy gear user, but in the worst case it can lead to very expensive, time consuming and reputation damaging litigation.Register Today

Gear Manufacturing and Inspection

May 2–4—Marriott Cincinnati North, Cincinnati, OH

While function and rating are important factors in a successful gear design, to be truly optimal and successful, the gear designer must also design the gears to be manufactured and inspected. In this course, therefore, we will address key factors in a wide variety of manufacturing and inspection processes to enable the gear designer to better design optimal gears considering both rating and the necessary manufacturing and inspection processes to produce the gears as designed.Register Today

Gear Failure Analysis

November 14–16—Chicago, IL

While the spring class in May is sold out, there is space available for the November class at the AGMA National Training Center. Explore gear failure analysis in this hands-on seminar where students not only see slides of failed gears but can hold and examine over 130 specimens with the same failure modes covered in the seminar. Approximately half of the course time consists of students in groups identifying failure modes on failed gears and working on a case study. Microscopes are available to examine failed specimens.Register Today

[please visit our sponsor]

Seminar: Methods and Best Practices for Gear Process Engineering

May 9 to 11, 2023 - Don’t miss this three-day seminar featuring 8 Industry

Experts presenting comprehensive training for new gear process engineers.

The course features a full day on heat treat distortion. The seminar is sponsored

by Arvin Global Solutions and will be held at the Northern Illinois University

Facility in Naperville, Illinois.

Click here for More Information.

Webinar: High Tech Applications for Cycloidal Reducers

Join us on 3/31 for this live event to learn why cycloidal reducers can often be the best choice for precision motion applications in robotics, medical/dental, aerospace/defense, machine tools and many other industries where low backlash and precision motion are required.

Register Today

Fisher Barton Expands and Builds The Turning Center of Excellence

Fisher Barton has selected MSI General Corporation for the design and construction of its new industrial building and site development for Accurate Specialties’ Turning Center of Excellence on Bluemound Road. To kick off construction, a groundbreaking ceremony took place Tuesday, March 21 at 10:00 AM.

Read More

AGMA Announces New Board of Directors and Officers at Annual Meeting

Power Transmission Engineering

The American Gear Manufacturers Association (AGMA) has changed its board of directors. These changes took place at the 2023 AGMA Annual Meeting in Lake Buena Vista, Fla.Read More

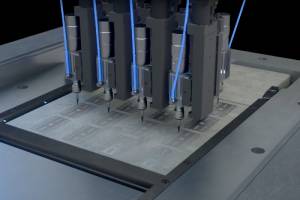

How Desktop Digital Manufacturing Impacts Abrasive Waterjet Cutting

The Fabricator

Desktop abrasive waterjet cutting is one process among a growing number of technologies in what’s become known as desktop digital manufacturing. The concept has created new possibilities for product designers. The time spent going from an initial design concept to a final product is no longer the hurdle it once was. This is a direct result of the democratization of manufacturing.Read More

Index Launches Newly Developed Training Program for Junior Technicians

Gear Technology

Index has announced the launch of the Index Technician Development Program (ITDP), a new, eight-month formal training program for junior technicians. Developed in response to the ongoing skilled labor shortage, the ITDP incorporates both classroom and hands-on instruction, including two months spent at the company’s global headquarters in Germany.Read More

|  |

Aerospace Recovery Progresses but Industry Awaits 2023 Liftoff

The Manufacturer

Global aircraft orders for February 2023 saw a relatively positive month with 104 aircraft orders placed, which compared to February 2022 is a 31 percent decrease. Aircraft orders for single-aircraft decreased by 40 per cent, however, orders for wide-body aircraft increased 53 percent indicating a change in the pace of wide-body recovery which until February 2023 has been at a much slower pace.Read More

Endeavor3D Joins Exclusive List of HP Digital Manufacturing Partners

TCT Magazine

Endeavor 3D, a leading additive contract manufacturer, has been promoted to HP Digital Manufacturing Partner. Endeavor 3D is committed to providing innovative solutions that improve efficiency, reduce costs, and open up new possibilities for engineers, designers, and researchers for additive manufacturing in North America.Read More

Leaning on AGVs to Drive the Future of Commerce

Automation.com

While some might consider technology that’s more than 50 years old to be outdated, Automated Guided Vehicles (AGVs) have evolved and are making a resurgence as a low-entry automation application. For warehouses and distribution centers (DCs) considering automation, the AGV benefits—improved safety, reduced operating and labor costs, use in undesirable locations, and decreased product damage—are hard to pass up.Read More

|  |

Charging Infrastructure and the Response of Utility Providers are Vital to the Success of E-Mobility

Business Review

Electric vehicle (EV) adoption has accelerated faster than predicted. Globally, EV sales doubled in 2021 and jumped 55% in 2022 to account for 13% of all vehicles sold. If this trend is to continue, however, the e-mobility ecosystem must collaborate around “Six essentials for mainstream EV adoption.”Read More

Smart Collaboration: Shaping the Factories of the Future

Forbes

At this point, most manufacturers have at least started their journey toward a smart factory transformation. They are making investments in critical advanced technologies—cloud, edge computing, and 5G—that are essential to connectivity and the cornerstone of any smart factory.Read More

|  |