[please visit our sponsor]

Detailed Gear Design

April 16–19—The Westin Arlington, Arlington, VA

There is a distinct difference between “designing” a gear and “optimizing” a gear design. In this course, we will address the optimization process via an understanding of those factors beyond basic banding and pitting ratings. Optimization may focus on load capacity, economy of production, or minimization of the overall gear system envelope. In this course, we will learn how to improve gear designs via optimization and gain new insight into concepts presented through illustrations and demonstrations. Explore all factors that go into good gear design from life cycle, load, torque, tooth, optimization, and evaluating consequences.Register Today

EV Automotive Transmission System Design

April 23–25—The Graduate Hotel; Ann Arbor, MI

This course will cover all aspects of gearbox concept, development, design, and through the initial stages of analysis as related to product requirements. We will review all the most common EV transaxle architectures, power flow and layout and the ‘whys’ of packaging as such. Independent of the architecture and/or layout, there are many similarities in the functional and operational requirements of an EV transaxle gearbox. We will work through all of those and develop a workable set of requirements that will then be used as the design basis. From a high-level point of view the ‘Big’ difference between transaxles for EVs (Electric Vehicles) and transmissions designed for more traditional Manual Transmissions (MTs) and / or Automatic Transmissions (ATs) is the lack of the ‘noisy’ internal combustion engine or ICE motor.Register Today

Integration and Trade-offs in Gear and Bearing Systems

April 23 – 24, 2024 | Ann Arbor, MI

The purpose will be to cover the concurrent design and analyses of gears and bearings in integrated systems like gearboxes, transmissions, and electric motor drives, so as to allow for good integration and faster optimization of the overall system. This will help gear engineers and suppliers better determine the trade-offs with the bearings, help bearing engineers and suppliers similarly with the gears, and system engineers better understand both.Register Today

Gear Manufacturing and Inspection

May 7–9—Sheraton Suites; Wilmington, DE

While function and rating are important factors in a successful gear design, to be truly optimal and successful, the gear designer must also design the gears to be manufactured and inspected. In this course, therefore, we will address key factors in a wide variety of manufacturing and inspection processes to enable the gear designer to better design optimal gears considering both rating and the necessary manufacturing and inspection processes to produce the gears as designed.Register Today

[please visit our sponsor]

Take your gear grinding to a whole new level

Leave it to MTB to develop a Recontrol/Retrofit Package that takes your older Form and Thread Grinding Machines to the performance levels of a new machine – all with less lead time and for a fraction of the cost. Available for all popular makes and models, both FANUC and Siemens CNC.

Learn More

Savings! - Precision Gear Machine Shop Closure

Precision Gear Machine Shop Closure Due to Owner Retiring - Koro Industries - Maple Grove, MN - Online Auction, Consisting Of:

Air Compressors, CNC Automatics, CNC Lathes, CNC Machining Centers, CNC Gear Hobbers, Gear Hobbers, Hob Sharpeners, Gear Deburring, Gear Checkers, Grinding, Hone, Lathes, Mills, Inspection Equipment, Tooling & More!

Read More

Unlocking infinite possibilities through efficient transmission with WORM drives

WORM drives enable precise motion, excel in tight spaces, and meet high torque demands in robotics, conveyors, and automotive sectors.

As industries evolve, they stand as enablers of progress, unlocking infinite potential with reliability.

CHUN YEH GEAR can manufacture - Max. Module: M10, Accuracy Capability: DIN 1, AGMA 14, JIS 0.

Read More

Star Cutter Names Andrew Epstein Vice President of Human Resources

Gear Technology

Star Cutter Company has appointed Andrew Epstein as Vice President of Human Resources (HR). Epstein oversees all HR functions for the Star Cutter family of companies, guiding HR resources across global locations and analyzing HR strategies. As a member of the Executive Leadership Team, he reports to the Chief Financial Officer, Becky Grech.Read More

The Bearing Show Examines Bearing and Lubrication Ecosystem

Power Transmission Engineering

The Bearing Show is North Americas newest exhibition and conference, connecting the evolving needs of bearings end-users with the latest technologies serving, OEM development, maintenance professionals and R&D engineers. Meet visitors from OEM’s, machine manufacturers, industrial plants, global distributors, and more. Matching the needs of end-users with the innovation and opportunities occurring throughout the supply-chain is essential. PTE recently interviewed Thomas Harris, event director, Lubricant Expo and The Bearing Show North Americas, to discuss the evolution of the event and what to expect from the show in late March.Read More

Rivian Expands Lineup: Meet R2, R3

The EV Report

Rivian recently introduced its new midsize vehicle platform, marking a significant expansion of its product lineup with the R2 and R3 series, including a high-performance variant, the R3X. Built on a groundbreaking midsize platform, these vehicles are designed to blend Rivian’s signature performance, capability, and utility into models that are more accessible to a broader audience. With a starting price of around $45,000 for the R2, Rivian is set to redefine the electric vehicle (EV) market, offering a blend of adventure-ready features and everyday usability.Read More

|  |

Technidrive Invests in Faster Development Cycles

AZO Materials

Industrial drives specialist, Technidrive, has invested in a state-of-the-art 3D printer, located at its Northern Ireland facility. The investment was driven by a need to provide faster development cycles and high-quality products.Read More

Triumph Awarded Contract from MD Helicopters on MD500

PR Newswire

Triumph Group, Inc. announced that its Geared Solutions business in Macomb, Michigan has been awarded a long-term agreement from MD Helicopters to manufacturer and assemble main rotor gearbox transmissions for the MD500 platforms. TRIUMPH has supported MD Helicopters for over two decades, producing over 400 gearboxes for this program. With this contract extension, TRIUMPH will continue to supply helicopter transmissions and transmission spare parts for the MD500 program.Read More

ZF’s first zero-emission factory is model plant for global production network

Autocar Professional

ZF has opened its first zero-emission factory at the production site for power electronics in Klášterec in the Czech Republic, after a renovation period of just under a year and a half. The plant, which is part of the Electrified Powertrain Technology division, supports the company’s efforts to achieve climate neutrality across all value chains by 2040. It will be used as the blueprint for all ZF plants worldwide.Read More

|  |

Scout Motors breaks ground on $2B EV plant after environmental delays

ManufacturingDive

Scout Motors, a Tysons, Virginia-based automotive company and subsidiary of Volkswagen Group, broke ground recently on its $2 billion electric vehicle plant in Blythewood, South Carolina, after a roughly three-month hiatus, according to the company. The facility will produce about 200,000 all-electric trucks and SUVs each year.Read More

Honest Planning and Soft Landings: Highlights From AMT’s 2024 Winter Economic Forum

AMT

At the AMT Winter Economic Forum, economists predicted the upcoming year will feature several opportunities for manufacturers as the economy comes in for a soft landing, including 8% growth in manufacturing technology orders. Is your company ready?Read More

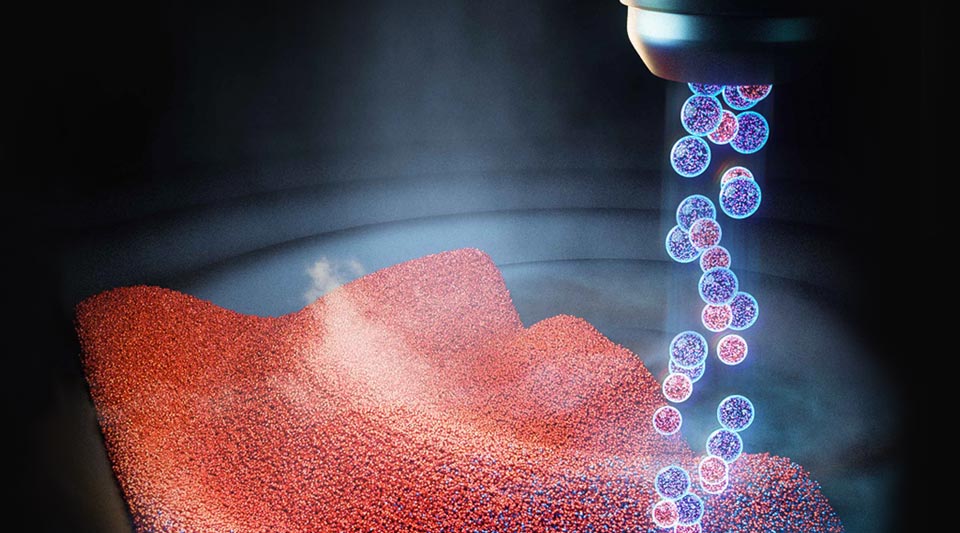

New 3D Printing Method Cuts Material Development Time in Half

ASME

The speed of material development must keep pace with technology advancements to maintain R&D and the rate of discovery and invention. High-tech, next-generation technologies such as clean energy, biomedicine, nanoelectronics, and environmental sustainability depend on new materials with highly-specific mechanical and chemical properties. However, material discovery and commercialization is still mostly a trial-and-error process that is slow, labor-intensive, and expensive, especially for nanomaterials.Read More

|  |