[please visit our sponsor]

Advanced Concepts of Bearing Technology

May 12–15—The Royal Sonesta; Minneapolis

This course builds on the foundations of the essential course and challenges the experienced engineer in areas such as failure modes, friction and wear, fatigue life calculation methods and load distribution. This course is exceptional for engineers with 2–3 years of work experience in bearings or past attendees of the Essential Concepts of Bearing Technology.Register Today

Fundamentals of Parallel Axis Gearing

May 13–15—The Royal Sonesta; Minneapolis

Gain a solid and fundamental understanding of gear geometry, types and arrangements, and basic design principles. Starting with the basic definitions of gears, conjugate motion, and the Laws of Gearing, learn the tools needed to understand the inter-relation and coordinated motion operating within gear pairs and multi-gear trains. Basic gear system design process, gear measurement and inspection techniques will also be explained.Register Now

Analytical Gear Chart Interpretation

May 20—Live Online Course

This course is an introduction to the methodology of analytical gear inspection and the evaluation and interpretation of the resulting data. The application of this information to identify and correct manufacturing errors will begin to be explored. Additionally, it reviews chart interpretation and applies inspection data to understand the causes and cures of manufacturing errors. Many chart examples are used to understand cause and effect.Register Today

Gear Manufacturing & Inspection

May 6–8—Kimpton Hotel Monaco; Philadelphia

While function and rating are important factors in a successful gear design, to be truly optimal and successful, the gear designer must also design the gears to be manufactured and inspected. In this course, therefore, we will address key factors in a wide variety of manufacturing and inspection processes to enable the gear designer to design optimal gears better considering both rating and the necessary manufacturing and inspection processes to produce the gears as designed.Register Now

[please visit our sponsor]

Optronic® Control no longer Optimal? Re-Control It!

Machine Tool Builders can replace the Optronic CNC based controller on your Profile/Form grinder with NEW controls & drives. MTB includes on-board dressing & customized conversational programming at a fraction of the cost of a new machine. Your place or ours, we’re ready to pick up wrenches. Call us today!

Contact MTB Today

The AGMA Fall Technical Meeting Process

AGMA’s Fall Technical Meeting (FTM) is the best place in the U.S. to share gear manufacturing research. If you want to write a paper and present, here is how it works.

Read More

SKF Completes Divestment of its Ring and Seal Operation in Hanover, PA

SKF has completed the previously announced divestment of its ring and seal operation in Hanover, Pennsylvania, USA, to Carco PRP Group for a total enterprise value of USD 215 million, corresponding to approximately SEK 2.1 billion. The divestment will result in a capital gain amounting to approximately SEK 0.8 billion in Q2 and will be reported as Items affecting comparability.

Read More

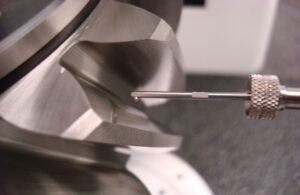

Helios Helps American Precision Gear Achieve Quality and Productivity

Gear Technology

At American Precision Gear, quality isn’t just a priority — it’s the foundation of everything they do. The shop specializes in high-precision miniature gears for aerospace, defense, and medical applications, where the strictest tolerances are non-negotiable. Helios Gear Products partnered with American Precision Gear to integrate the MZ 1000 D-Drive into their production.Watch the Video

Bringing an AI boost to additive manufacturing

ManufacturingDive

The global additive manufacturing industry was valued at over $20 billion in 2023. Additive manufacturing is slated to grow rapidly as companies use AI to experiment with designs, make the production process more efficient, increase accuracy and streamline supply chains. From initial design and simulation to real-time quality control, AI is boosting productivity and profitability, fueling innovation and addressing critical skills shortages in the manufacturing sector.Read More

Industrial Executives’ Sentiment Was Slipping Even Before Tariffs

IndustryWeek

The economy and the business climate have taken on a decidedly before-and-after vibe since President Trump’s April 2 event detailing the tariffs he and his team devised for most of the United States’ trading partners. And while he retreated from several measures less than a week later, the ones left in force—led by the across-the-board minimum 10% tariff rate that came into effect April 5—are reshaping trade flows around the globe.Read More

|  |

3D Printing Meets High Performance in Czinger Hypercars

ASME

What do you get when combining additive manufacturing with a relentless need for speed? A hypercar engineered with precision, utilizing rapid prototyping and 3D printing to create a lightweight yet incredibly strong structure.Read More

Manufacturing PMI at 49%

PR Newswire

New Orders and Backlogs Contracting; Production and Employment Contracting; Supplier Deliveries Slowing; Raw Materials Inventories Growing; Customers' Inventories Too Low; Prices Increasing; Exports Contracting and Imports GrowingRead More

Indiana's scalable model for closing the manufacturing talent gap

World Economic Forum

Some 78 million new jobs will be created globally in the next five years, according to the World Economic Forum’s The Future of Jobs Report 2025. In the US manufacturing sector alone, there could be as many as 3.8 million new employees needed by 2033, yet nearly half of these roles are at risk going unfilled if manufacturers don’t improve the attractiveness of the sector and address skill gaps.Read More

|  |