[please visit our sponsor]

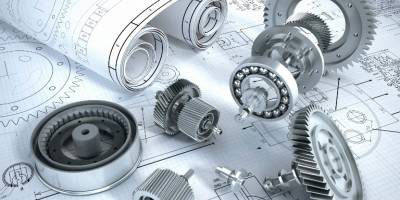

Fundamentals of Gear Design and Analysis

June 6–8—Hilton Rosemont, Rosemont, IL

Gain a solid and fundamental understanding of gear geometry, types and arrangements, and basic design principles. Starting with the basic definitions of gears, conjugate motion, and the Laws of Gearing, learn the tools needed to understand the inter-relation and coordinated motion operating within gear pairs and multi-gear trains. Basic gear system design process, gear measurement and inspection techniques will also be explained.Register Today

Gearbox Systems Design

June 20–22—Sheraton Sand Key Resort, Clearwater Beach, FL

This course focuses on the supporting elements of a gearbox that allow gears and bearings to do their jobs most efficiently. Learn about seals, lubrication, lubricants, housings, breathers, and other details that go into designing gearbox systems. This course is intended for gear design engineers; management involved with designing and manufacturing gearing-type components; metallurgists and materials engineers; laboratory technicians; quality assurance technicians; furnace design engineers; and equipment suppliers.Learn More

Design Basics for Spur and Helical Gears—Summer

June 27, 12:00 pm–4:00 pm (EST)—Live Online Virtual Training

Learn how to develop and understand customer gear drive application specifications and target performance expectations. Review, calculate and select basic gear terminology variables and design parameters which define tooth bending and contact rating safety factors on two real-life examples. Learn how to optimize gear fatigue Safety Factors for a given target design life and fit new gear designs and ratios into existing center distance using profile shift. Use commercially available software to develop gear geometry factors and calculate and optimize gear set power density and performance. Review common gear failure modes if the design or final accuracy does not meet application requirements. Discuss the time and cost of more than 20 other gear drive component functions and drive development steps through prototypes to shipment of compliant assembled production drives. There will be an opportunity to discuss gear design challenges that may be unique to participant industries.Register Today

Analytical Gear Chart Interpretation—Summer

June 29, 12:00 pm–4:00 pm (EST)—Live Online Virtual Training

This course is an introduction to the methodology of analytical gear inspection and the evaluation and interpretation of the resulting data. The application of this information to identify and correct manufacturing errors will begin to be explored. Additionally, it reviews chart interpretation and applies inspection data to understand the causes and cures of manufacturing errors. Many chart examples are used to understand cause and effect.Learn More

[please visit our sponsor]

Registration is Now Open!

Join the entire motion power supply chain at Motion + Power Technology Expo 2023 as we get back to full-scale this year. Expect to meet with suppliers, explore automation equipment, and find solutions and opportunities that are going to help your business thrive through the coming year.

Register Today

ELIN Motoren and Voith Launch Electric Motors for Tunnel Boring Machines

ELIN Motoren and Voith launch the first electric motor with integrated safety coupling for the main drive of tunnel boring machines.

Read More

New Verisurf 2024 Featured at Control

Verisurf 2024 is the latest release of the popular measurement software for automated quality inspection, reporting, scanning, reverse engineering, tool building, and assembly guidance. The software is powerful, flexible, and easy to use for measurement applications across the manufacturing enterprise.

Read More

Live from Fort Worth, It's SNL!

Gear Technology

Senior Editor Aaron Fagan describes three great days (May 17–19) with AGMA members who descended on Fort Worth, Texas, from all corners of the country (and industry!) for the 2023 Strategic Networking and Leadership Forum sponsored by Gleason Corporation, WD Bearings, Blaser Swisslube, and Specialty Steel Treating. Professionals from gear shops and OEMs alike gathered to share their experience and insight about where we are as an industry and where we are going.Read More

EVs are Driving Technology in the Gear Industry

Gear Technology

A significant amount of work is being done to advance the technology of gears specifically for use in electric vehicles. No longer hidden by the noise of the internal combustion engine, the transmission has taken center stage as the noisiest component in most electric-driven cars.Read More

The Future of AM

SME

What’s next for additive manufacturing? How fast will it grow, and what new applications are the most promising? Product development and manufacturing professionals across various sectors are eager for information to anticipate how the technology and its application will continue to develop as they consider adoption and investment strategies.Read More

|  |

Five Ways Drone Technology is Improving

ASME

Unmanned aerial vehicles—or drones—are pushing boundaries everywhere from construction sites to combat. The global commercial drone market was valued at about $8 billion in 2022, and is projected to reach $47 billion by 2030. This growth reflects the rapid advancement in drone designs and supporting technologies, especially automation and artificial intelligence (AI).Read More

How Siemens, Deloitte and Wichita State University are Building the Next Generation of Smart Factories

ManufacturingDive

The Smart Factory project aims to advance manufacturing technologies and help more companies integrate tools like digital twins into their own operations.Read More

Biden-Harris Administration Announces Strategies to Train and Connect American Workers to Jobs

The White House

Last week, the Biden-Harris Administration is announcing new efforts to ensure all Americans can access the good jobs created by the President’s Investing in America agenda, including the American Rescue Plan, the Bipartisan Infrastructure Law, the CHIPS and Science Act, and the Inflation Reduction Act.Read More

|  |

How Do Automated Guided Vehicles Improve Manufacturing?

Manufacturing.net

The manufacturing industry is no stranger to automation. Until recently, however, most has been in the form of stationary robotics. The recent rise of automated guided vehicles (AGVs) promises to bring robots’ advantages to other workflows. As a result, more manufacturers are considering the benefits of AGVs.Read More

Unlocking the Value Potential of Additive Manufacturing

Manufacturing Tomorrow

Hard to believe that 3D printing has been with us for more than 40 years. Yet, additive manufacturing (AM), which can deliver enormous value, is still greatly underutilized. When properly implemented, the technology can reduce material waste and energy costs, improve part reliability, decrease lead times, reduce or eliminate the need to carry inventory and optimize the production of legacy parts.Read More

ABB Predicts Top US Robotics Trends

Robotics Tomorrow

With annual revenue in the U.S. robotics market expected to grow at 5.62 percent1(CAGR), resulting in a market volume of over $9bn by 2027, John Bubnikovich, ABB US Robotics Division President, is making several predictions on key trends in in robotics automation in the US for 2023 and beyond.Read More

|  |