[please visit our sponsor]

Gearbox Systems Design

June 4–6—Sheraton Sand Key Resort; Clearwater, FL

This course focuses the supporting elements of a gearbox that allow gears and bearings to do their jobs most efficiently. Learn about seals, lubrication, lubricants, housings, breathers, and other details that go into designing gearbox systems.Register Now

Laser Powder DED—Technical Overview

June 5—Free Emerging Tech Webinar

By using inert argon gas to continuously spray metal powder from a nozzle, the laser melts and solidifies the powder with base materials to manufacture an intended shape. DED metal 3D printers are used for multi-layer materials and components composed of multiple different materials. With an optional second hopper providing powdered metal, LAMDA systems can switch materials during a manufacturing process producing functional gradient materials, which are printed by changing the blend of materials during the manufacturing process. Powder directed energy deposition offers a higher deposition rate than powder bed fusion, and, with the introduction of new technology, the process is ideal for printing very large structures as well as adding features to existing components and for repair.Register Now

Loaded Tooth Contact Analysis

June 13—Live Online Course

Evaluation of loaded tooth contact and development of tooth modifications using commercially available software to improve and apply a realistic load distribution factor Km in gear rating calculations. Two real-life gearing examples will be presented in the course, one will have a cantilever-mounted pinion, the other a shaft pinion straddled non-symmetrically by bearings. Both examples demonstrate component deflections under load which significantly reduce tooth mesh contact which is then corrected with developed helix and profile modifications.Register Now

Involute Spline Design and Rating

June 17–18—Live Online Course

This course will address both geometry and rating of involute splines of various types. The types of spline joints and their applications will be discussed. Spline configuration variations, including half depth, full depth, and special function designs, will be addressed. Both fixed and flexible spline configurations will be examined in terms of usage and design. Lubrication methods, including grease, oil bath, and flowing oil, as well as coatings appropriate for various spline applications, are examined. Shear and compressive stress rating methods are discussed with analyses methodology presented in both equation and graphical methodology via various rating charts.Register Now

5 Ways to Reduce Risk of an Organization Being Hacked

June 20—Free Emerging Tech Webinar

In today’s rapidly evolving digital landscape, the threat of cyber-attacks looms larger than ever before. As malicious actors continuously refine their strategies, businesses of all sizes find themselves at an increased risk of being compromised. “5 Ways Your Company can Reduce the Risk of Being Hacked” delves into strategies that organizations can implement to bolster their cybersecurity posture.Register Now

Fundamentals of Gear Design and Analysis

June 25–27—Embassy Suites O’Hare; Rosemont, IL

Gain a solid and fundamental understanding of gear geometry, types and arrangements, and basic design principles. Starting with the basic definitions of gears, conjugate motion, and the Laws of Gearing, learn the tools needed to understand the inter-relation and coordinated motion operating within gear pairs and multi-gear trains. Basic gear system design process, gear measurement, and inspection techniques will also be explained.Register Now

[please visit our sponsor]

Smart Move: Save Big with a CNC Recontrol

It’s hard to stay competitive with older gear machines using outdated controls. New machines are often too costly a solution – and you’ll wait months for delivery. The smart move is an MTB Recontrol. In just three months, and for a relative fraction of a new machine investment, we can recontrol most CNC gear machines – and bring them up to profitable new performance levels.

Learn more. Download the Whitepaper

MAR – a landmark in the world of grinding machines

- Natural granite machine beds

- Electro spindles

- Torque rotating grinding wheel turret

- Ball screws or linear motor technology

- Glass scales

- Multi-wheel OD/ID platforms available

- Siemens or Fagor CNC controls

- Universal Torque workhead with integrated angular position control

- MAR designed simplified HMI

- Compact machine design

Read More

Unlocking infinite possibilities through efficient transmission with WORM drives

WORM drives enable precise motion, excel in tight spaces, and meet high torque demands in robotics, conveyors, and automotive sectors.

As industries evolve, they stand as enablers of progress, unlocking infinite potential with reliability.

CHUN YEH GEAR can manufacture - Max. Module: M10, Accuracy Capability: DIN 1, AGMA 14, JIS 0.

Read More

AGMA Announces Next-Generation Award Recipient at 2024 Strategic Networking & Leadership Forum

Gear Technology

The American Gear Manufacturers Association (AGMA) honored gear industry professional, Michael Weas, at its 2024 Strategic Networking & Leadership Forum in Milwaukee, WI, on Thursday, May 2. The Next-Generation Award honors upcoming gear industry leaders for their innovative work and significant contributions to and betterment of the gear industry.Read More

New Eco-Friendly Lubricant Additives Protect Turbine Equipment, Waterways

ScienceDaily

While environmentally acceptable lubricants are available, they are not optimized with additives that can greatly improve performance while posing minimal environmental impact if accidentally released. To create nontoxic, biodegradable and high-performing lubricant additives for water power turbines, researchers turned to ionic liquids, or ILs: organic liquid salts that mix well with oil, reduce friction between bearings and gears, and are stable in a range of temperatures.Read More

Automotive Manufacturer Orders Second Endo Generator

Heat Treat Today

An automotive manufacturer in South America has recently placed a follow-up order for a second Endothermic generator from a manufacturer of industrial process control, automation, and digitalization solutions with North American locations. UPC-Marathon, a Nitrex company, installed a 200 m³/h EndoFlex unit last year. The new generator, with a similar capacity, aims to enhance stability, to ensure consistent composition and gas flows, and to prioritize quality of automotive gear boxes while achieving efficiencies in heat treatment operations.Read More

|  |

A3 Announces First Winners of the New Automate Innovation Awards

Gear Technology

The Association for Advancing Automation (A3), North America’s largest automation trade association representing more than 1300 organizations, has announced the winners of the inaugural Automate Innovation Awards. This year’s winners—AMD, ECM and GrayMatter Robotics—were honored at a special ceremony on May 6 at Automate 2024 in Chicago.Read More

Nord Introduces Gear Motor QR Codes for Faster Access to Product Information

Power Transmission Engineering

If you’ve recently purchased a Nord Drivesystems gear motor, you may have noticed a new sticker with a QR code located on the unit. Quick Response (QR) codes can store a wide range of data and enable the user to access information almost instantly. These stickers are a new development in Nord’s expansive digital services and provide users quick access to product specifications, documentation, and service requests on-the-spot via their mobile device.Read More

Are EVs Really Much Heavier Than Their ICE Equivalents?

The Driven

An interesting question and comment I have started hearing more often at my public talks is “but aren’t EVs so much heavier than internal combustion engine cars, meaning they do more damage to roads?” If EVs were significantly heavier than ICE cars, then perhaps that comment could be worth exploring. However, my previous checks have shown they aren’t all that much heavier.Read More

|  |

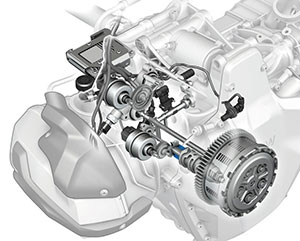

BMW Go Clutchless with Automated Shift Assistant Prototype

Motorcycle News

BMW are looking to revolutionize the way we change gear by launching a new automatic transmission, dubbed Automated Shift Assistant (ASA) offering both a manual and full auto setting. The technology was revealed to MCN at an exclusive event at the BMW Enduro Park Hechlingen, near Munich last week, with the brand running a live demonstration of the technology, in pre-production form, on a BMW R1300GS adventure bike.Read More

Digital Twin-Based Approach for a Multi-Objective Optimal Design of Wind Turbine Gearboxes

MDPI

This paper focuses on the development of a digital twin-based approach for the modelling and simulation of WT gearboxes with the aim to improve their design, diagnosis, operation, and maintenance by providing insights into their behavior under different operating conditions.Read More

Geartek Expanding Operations in Alcorn County

DeSoto County News

Hydraulic gear pump and motor manufacturer Geartek is expanding its operations in Corinth. The project is a $3.8 million investment that will create two new jobs. A division of Hydraulic Analysis, Inc., Geartek’s products are used in a variety of industries, including forestry, energy, site clearing and mining. The company has long-established local ties to Corinth and is expanding its existing manufacturing facility by approximately 8,500 square feet to accommodate new manufacturing equipment for added production capacity.Read More

The Gears of the Gardiner Mill

The East Hampton Star

This photo, taken in 1999 during a tour of the Gardiner Mill, shows its inner gears. The present-day Gardiner Mill was constructed in 1804 on the eastern side of Town Pond, just south of St. Luke’s Episcopal Church. A previous mill, built near the same place in 1769, was replaced by the more technologically advanced 1804 smock mill design.Read More

|  |