[please visit our sponsor]

EV Standards Development Meeting at LIFT

June 11—Detroit, MI

For 108 years, AGMA has been at the forefront of standards development for the gear and power transmission industry. Our first EV Town Hall in October 2023 showed that there is industry interest in developing more substantive information for gear manufacturers around electric vehicle technology. This could eventually lead to standards development. The AGMA Technical Division will host a second meeting to further discuss standards development. We are inviting gear and power transmission engineers who work directly on gear boxes for electric vehicles.Register Now

Loaded Tooth Contact Analysis

June 13—Live Online Course

Evaluation of loaded tooth contact and development of tooth modifications using commercially available software to improve and apply a realistic load distribution factor Km in gear rating calculations. Two real-life gearing examples will be presented in the course, one will have a cantilever-mounted pinion, the other a shaft pinion straddled non-symmetrically by bearings. Both examples demonstrate component deflections under load which significantly reduce tooth mesh contact which is then corrected with developed helix and profile modifications.Register Now

Involute Spline Design and Rating

June 17–18—Live Online Course

This course will address both geometry and rating of involute splines of various types. The types of spline joints and their applications will be discussed. Spline configuration variations, including half depth, full depth, and special function designs, will be addressed. Both fixed and flexible spline configurations will be examined in terms of usage and design. Lubrication methods, including grease, oil bath, and flowing oil, as well as coatings appropriate for various spline applications, are examined. Shear and compressive stress rating methods are discussed with analyses methodology presented in both equation and graphical methodology via various rating charts.Register Now

Fundamentals of Gear Design and Analysis

June 25–27—Embassy Suites O’Hare; Rosemont, IL

Gain a solid and fundamental understanding of gear geometry, types and arrangements, and basic design principles. Starting with the basic definitions of gears, conjugate motion, and the Laws of Gearing, learn the tools needed to understand the inter-relation and coordinated motion operating within gear pairs and multi-gear trains. Basic gear system design process, gear measurement, and inspection techniques will also be explained.Register Now

Advanced Concepts of Bearing Technology

July 24–27—Embassy Suites O'Hare; Rosemont, IL

This ABMA course builds on the foundations of the essential course and challenges the experienced engineer in areas such as failure modes, friction & wear, fatigue life calculation methods and load distribution. This is an exceptional course for engineers with 2-3 years’ work experience in bearings or past attendees of the Essential Concepts of Bearing Technology.Register Now

[please visit our sponsor]

Smart Move: Save Big with a CNC Recontrol

It’s hard to stay competitive with older gear machines using outdated controls. New machines are often too costly a solution – and you’ll wait months for delivery. The smart move is an MTB Recontrol. In just three months, and for a relative fraction of a new machine investment, we can recontrol most CNC gear machines – and bring them up to profitable new performance levels.

Learn more. Download the Whitepaper

With the WORM drives, everything is high efficiency

Worm drives, the most compact gear system; provide high-ratio speed reduction and greatly increase torque. To be effective, it’s crucial that they are manufactured with high-quality standards to ensure all requirements are precisely met. CHUN YEH GEAR can manufacture - Max. Module: M10, Accuracy Capability: DIN 1, AGMA 14, JIS 0.

Read More

Liebherr Offers Electric Drive Solutions for Construction Machinery

Compact and lightweight – such is the most common requirement for the gearboxes of emission-free, electric drives. With seven basic gearboxes, the LPI series by Liebherr fulfills exactly this need for high power density.

Read More

Faulhaber Micromotors Optimizes Small Parts Assembly

Power Transmission Engineering

A "compact automation" is a mechatronic system that performs a whole series of consecutive production steps autonomously. "Compact" refers to the small dimensions, in the millimeter and centimeter range, of the products to be processed. Designing and constructing such systems is one of the core activities of the Austrian machine manufacturer STIWA. Its modular system LTM-CI has been optimized for small parts assembly. Linear and rotating micromotors from Faulhaber perform key tasks in these systems.Read More

How Humanoid Robots Can Help Narrow Gaps Between Automation and Labor

The Robot Report

The robotics industry has seen major growth and maturity in the past decade. Technology advances such as vision systems and computing power, along with the rise of artificial intelligence, have helped the industry grow in many ways. Robots also are getting cheaper and more affordable. Robots are taking a greater role and improving automation in many ways, but are humanoid robots the next step?Read More

ABB Robotics Expands Large Robot Portfolio

Gear Technology

ABB Robotics is continuing the expansion of its modular large robot portfolio with the introduction of the new IRB 7710 and IRB 7720. The new robots, combined with recently launched IRB 5710-IRB 5720 and IRB 6710-IRB 6740, offer a combined total of 46 different variants capable of handling payloads between 70 kg-620 kg, to give customers a new level of flexibility, greater choice and performance in their operations.Read More

|  |

Universal Robots and MiR Open New Robotics Hub in Denmark

Power Transmission Engineering

Universal Robots, the Danish collaborative robot (cobot) company, and MiR, the Danish manufacturer of AMRs (autonomous mobile robots), recently celebrated the grand opening of their new 215,000 sq. ft. headquarters in Odense, Denmark. Partners from UR and MiR's global ecosystems attended the event, including NVIDIA and Siemens, with whom Teradyne Robotics and its companies have recently announced several collaborations.Read More

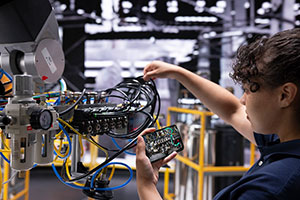

To Accelerate the EV Transition, Focus on the Workforce

Siemens

Is the electric-vehicle market slowing down or picking up? My news feeds are chock-full of commentary about the latest consumer trends and various predictions. Our view is more straightforward: EVs are coming. This is the future and there’s no turning back. Why? We simply cannot achieve our climate goals without them. The EV transition will significantly decarbonize a sector that’s the largest contributor of greenhouse gas emissions. As if that weren’t enough, the electric-vehicle sector is critical to our continued economic leadership and national security.Read More

Manufacturing for Tomorrow

Microsoft

After years of uncertainty from supply chain disruption and increased customer expectations, to changes in consumer demand and workforce shortages, manufacturing remains one of the most resilient and complex industries. Today, we are witnessing the manufacturing industry enter a transformative era, fueled by AI and new AI-powered industrial solutions.Read More

|  |

Motor-Gearbox-Electronics Development Platform for EVs

Electronics Weekly

Drive System Design (DSD) and Alvier Mechatronics have teamed up to create a development platform for electric vehicle drives. “The project leverages DSD’s expertise in rapid development engineering and Alvier Mechatronics’ experience in novel manufacturing methods for high-volume applications, material know-how and electromagnetic design,” according to DSD.Read More

Credentialing Adds Value to Training Programs

IEEE Spectrum

With careers in engineering and technology evolving so rapidly, a company’s commitment to upskilling its employees is imperative to their career growth. Maintaining the appropriate credentials—such as a certificate or digital badge that attests to successful completion of a specific set of learning objectives—can lead to increased job satisfaction, employee engagement, and higher salaries.Read More

NASA to Start Designing More Sustainable Jet Engine Core

NASA

NASA, alongside industry, will soon begin designing a new jet engine concept for the next generation of ultra-efficient airliners — officially graduating to the project’s next phase. As part of NASA’s goal to make the aviation industry more sustainable, the agency is developing a small core for a hybrid-electric turbofan jet engine that could reduce fuel burn by 10% compared to today’s engines.Read More

|  |