[please visit our sponsor]

Operator Precision Gear Grinding

July 24–25—Live Online Course

Explore precision gear grinding processes, machine input variables, kinematics, machine alignment, setup errors, pitfalls, common gear fatigue failures, and expectations related to finish ground gearing. Learn definitions of gearing component features, application loads, and process steps from blanking, through heat treatment to finished part ready to ship. Study aspects of Quality Assurance, Inspection Documentation, and corrective actions for measured non-conformances. Understand pre-heat treat, heat treatment distortion and post heat treatment operations including the how’s and why’s to produce finished gears that conform and perform to end-user expectations. Calculate gear form grinding cycle times for real-life examples for various accuracy levels on commercially available software.Register Now

Bevel Gear Systems Design

July 30–August 8—Live Online Course

Learn how to design and apply bevel gear systems from the initial concept through manufacturing and quality control and on to assembly, installation, and maintenance. Engage in a practical hands-on guide to the bevel gear design, manufacture, quality control, assembly, installation rating, lubrication, and, most especially, application.Register Now

Gear Heat Treatment Operator & Operations

August 6–8—Hotel Cleveland; Cleveland

This course provides the heat treat operator and operations team, the means to perform the heat treatment of steel gears in a manner that meets the AGMA and customer requirements in a safe and efficient manner. The course identifies the key requirements for proper processing. Sufficient metallurgical background is provided to allow the student to identify how this information relates to the required processing and properties of the gear.Register Now

Essential Concepts of Bearing Technology

August 6-8, 2024—Renaissance Cleveland Hotel; Cleveland

This course will give you an overview of the bearing industry as well as basic bearing types and applications. Knowledge of the key players, bearing types and terminology will ensure that everyone has a basic knowledge of the industry upon arrival. This course is specially designed for engineers and others with technical backgrounds that have limited exposure to bearings and need to adapt their technical training to bearings or seek an upgrade to their technical knowledge. The Essentials Course focuses on understanding basic tribology, bearing attributes and applications and explores the basic concepts around manufacturing methods, loads, lubrication and failure.Register Now

[please visit our sponsor]

Smart Move: Save Big with a CNC Recontrol

It’s hard to stay competitive with older gear machines using outdated controls. New machines are often too costly a solution – and you’ll wait months for delivery. The smart move is an MTB Recontrol. In just three months, and for a relative fraction of a new machine investment, we can recontrol most CNC gear machines – and bring them up to profitable new performance levels.

Learn more. Download the Whitepaper

Unlocking infinite possibilities through efficient transmission with WORM drives

WORM drives enable precise motion, excel in tight spaces, and meet high torque demands in robotics, conveyors, and automotive sectors.

As industries evolve, they stand as enablers of progress, unlocking infinite potential with reliability.

CHUN YEH GEAR can manufacture - Max. Module: M10, Accuracy Capability: DIN 1, AGMA 14, JIS 0.

Read More

Fast-Trac Jaw Nuts From Dillon Manufacturing Cut Jaw Change Time

Fast-Trac Jaw Nuts from Dillon Manufacturing allows users to change jaws in half the time, according to customers who have made the switch. This system lets users preassemble the jaws required for the next operation while the machine is running a separate job, thus minimizing jaw change time and maximizing productivity and profitability.

Read More

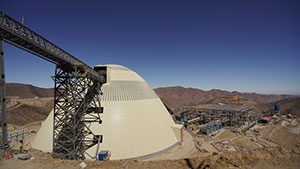

Innomotics Partners in Construction of World's First Digital Mine

Power Transmission Engineering

Innomotics, a Siemens Business, has partnered with Anglo American, one of the world’s leading mining companies, to develop a digital mining solution for Quellaveco copper mine, in Peru. In this context, Innomotics has provided a suite of Siemens technologies, to help Anglo American engineer, monitor, manage and run the mining operations from the earliest stages of design through commissioning and into production.Read More

Lithium Producers Bullish on Long-Term Demand Despite Recent Price Drop

Mining.com

The world’s largest lithium producers told a major industry conference this week they remain bullish on long-term demand for the electric vehicle battery metal despite the recent price plunge that has forced layoffs and curtailed expansions. Once a niche metal used primarily in ceramics and pharmaceuticals, lithium demand has grown rapidly over the past decade. But oversupply from China and a softening of aggressive EV adoption rates has dragged lithium prices down more than 80% in the last year.Read More

Nanocomposite Coatings

Gear Technology

Wear, friction, and corrosion constantly threaten mechanical components, causing efficiency losses and decreased component life. As more efficient designs and material advancements are introduced, these threats continue to be a point of frustration for engineers and end users.Read More

|  |

Additive Manufacturing: The Next Steps

GlobalSpec

Metal additive manufacturing (AM) has experienced widespread growth in our understanding and curiosity. It has reached an inflection point that will be on full display in the Additive Manufacturing Sector, accelerated by Formnext, at IMTS 2024, held Sept. 9-14 at McCormick Place in Chicago, Illinois.Read More

Driving Development in the Fast Machining of Complex Parts

Automation.com

Analysis by McKinsey & Co finds that the additive manufacturing (AM) industry is now worth an estimated €13.4 billion with a 22% annual growth rate. But the report also finds that, despite the benefits offered by AM, there are still significant barriers preventing mass uptake. Here, Ross Turnbull, Director of Product Engineering and Business Development at ASIC company Swindon Silicon Systems discusses these challenges, and how smarter sensors can help overcome them.Read More

On the GOES

NASA

On June 14, 2024, NOAA’s (National Oceanic and Atmospheric Administration) last Geostationary Operational Environmental Satellite, GOES-U, started its journey from the Astrotech Space Operations facility to the SpaceX hangar at Launch Complex 39A at NASA’s Kennedy Space Center in Florida.Read More

|  |

Humanoid Robots Being Tested for Warehouse Automation

IoT World Today

GXO, one of the world’s largest logistics firms, is testing humanoid robots as part of a partnership with robotics developer Apptronik to automate warehouse work, including item picking. With more than 970 facilities that span some 200 million square feet, GXO is hoping to augment its operations with what it describes as “AI-enabled warehouse buddies.”Read More

The Flying Five

Cutting Tool Engineering

"Humans make mistakes. Machines don’t,” said Kevin O’Neil, regional sales manager for the Southwest U.S. territory at Hermle USA Inc. in Franklin, Wisconsin. O’Neil covers California, Arizona, Colorado, Utah and New Mexico. By having a 5-axis machine to access five sides of a part in one setup, manufacturers of mission-critical aerospace components can increase part accuracy and reduce scrap by not having to re-fixture workpieces as many times as would be needed in a 3-axis machine, O’Neil explained.Read More

Navigating the Future: Unlocking the Benefits of Urban Air Mobility

Business Insider

As a leading provider of risk and insurance solutions for Urban Air Mobility (UAM) companies around the world, Global Aerospace has tended to publish articles focused on the risks and challenges associated with urban aviation. In this edition of Insights, the focus is squarely on the benefits these revolutionary aircraft services will bring as a new era of urban transportation is created.Read More

|  |