[please visit our sponsor]

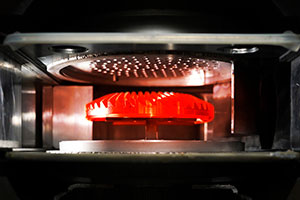

Eliminate Distortion by Engineering your Heat Treatment Quench with 4DQ

July 10—Free Emerging Technology Webinar

It is well known that distortion has and continues to present a challenge to the heat treater when hardening/carburizing gears. However, recent advances in quenching technology are improving the opportunity for improved distortion control. 4 Dimension High-Pressure Gas Quenching (4DQ) is a unique gas quenching process that combines a special quenching chamber design with part rotation to minimize distortion during the quenching process.Register Now

2024 Fall Technical Meeting (FTM)

October 7–9—Hyatt Hotel; Rosemont, IL

Technology is fundamentally changing the way manufacturing is done. The gear industry is faced with emerging trends and innovations that are challenging engineers to stay on course with cutting-edge technology to keep design, quality, materials, and analysis efficient. Researchers and gear engineers must communicate ideas with fellow experts in the field. AGMA’s annual Fall Technical Meeting (FTM) is the perfect forum in which to share research and to disperse knowledge for the benefit of the industry at a global level. Early Bird lasts until August 16. Advance is available after Early Bird until September 30. Academic discounts are available upon request.Register Now

Operator Precision Gear Grinding

July 24–25—Live Online Course

Explore precision gear grinding processes, machine input variables, kinematics, machine alignment, setup errors, pitfalls, common gear fatigue failures, and expectations related to finish ground gearing. Learn definitions of gearing component features, application loads, and process steps from blanking, through heat treatment to finished part ready to ship. Study aspects of Quality Assurance, Inspection Documentation, and corrective actions for measured non-conformances. Understand pre-heat treat, heat treatment distortion and post heat treatment operations including the how’s and why’s to produce finished gears that conform and perform to end-user expectations. Calculate gear form grinding cycle times for real-life examples for various accuracy levels on commercially available software.Register Now

Bevel Gear Systems Design

July 30–August 7—Live Online Course

Learn how to design and apply bevel gear systems from the initial concept through manufacturing and quality control and on to assembly, installation, and maintenance. Engage in a practical hands-on guide to the bevel gear design, manufacture, quality control, assembly, installation rating, lubrication, and, most especially, application.Register Now

Gear Heat Treatment Operator & Operations

August 6–8—Hotel Cleveland; Cleveland

This course provides the heat treat operator and operations team, the means to perform the heat treatment of steel gears in a manner that meets the AGMA and customer requirements in a safe and efficient manner. The course identifies the key requirements for proper processing. Sufficient metallurgical background is provided to allow the student to identify how this information relates to the required processing and properties of the gear.Register Now

Essential Concepts of Bearing Technology

August 6–8—Hotel Cleveland; Cleveland

This course is specially designed for engineers and others with technical backgrounds who have had limited exposure to bearings and need to adapt their technical training to bearings or seek an upgrade to their technical knowledge. The Essentials Course focuses on understanding basic internal geometry, tribology, bearing attributes, and applications and explores the basic concepts around manufacturing methods, loads, internal load contacts, lubrication, and failure.Register Now

[please visit our sponsor]

Smart Move: Save Big with a CNC Recontrol

It’s hard to stay competitive with older gear machines using outdated controls. New machines are often too costly a solution – and you’ll wait months for delivery. The smart move is an MTB Recontrol. In just three months, and for a relative fraction of a new machine investment, we can recontrol most CNC gear machines – and bring them up to profitable new performance levels.

Learn more. Download the Whitepaper

With the WORM drives, everything is high efficiency

Worm drives, the most compact gear system; provide high-ratio speed reduction and greatly increase torque. To be effective, it’s crucial that they are manufactured with high-quality standards to ensure all requirements are precisely met. CHUN YEH GEAR can manufacture - Max. Module: M10, Accuracy Capability: DIN 1, AGMA 14, JIS 0.

Read More

Fast-Trac Jaw Nuts From Dillon Manufacturing Cut Jaw Change Time

Fast-Trac Jaw Nuts from Dillon Manufacturing allows users to change jaws in half the time, according to customers who have made the switch. This system lets users preassemble the jaws required for the next operation while the machine is running a separate job, thus minimizing jaw change time and maximizing productivity and profitability.

Read More

New Managing Director at KISSsoft AG

Gear Technology

Effective July 1st, 2024, Dr. Ulrich Kissling, founder and Managing Director of KISSsoft AG steps down as Managing Director of KISSsoft AG as he partially transitions to retirement. Dr. Kissling will continue with KISSsoft AG focusing on representation for Gleason / KISSsoft AG on various technical committees and providing technical support to the Engineering and Sales teams.Read More

AGMA Foundation Scholarship Applications Increase 300 Percent Over Previous Year

agma.org

The American Gear Manufacturers Association Foundation (AGMA Foundation) Scholarship Program received 25 applications for 2024, a 300 percent increase from 2023. Twenty-four applications came from undergraduates pursuing degrees in computer science, economics, mechanical, electrical, aerospace, and mechatronics engineering, and one application from a student pursuing a PhD in mechanical engineering.Read More

David Brown Santasalo Installs Complete Drive System Test Bed

Power Transmission Engineering

David Brown Santasalo (DBS) recently completed the installation of an enhanced complete drive system test bed at the Service Center in Chile. Customers in Chile will now have all their gearbox assemblies (electric motor + fluid coupling + gearbox) dynamically tested using DBS’ enhanced services. This means they can be sure that once a gearbox is commissioned into place, it will not have any unforeseen reliability issues or premature failures.Read More

|  |

Nano Dimension to Acquire Outstanding Shares of Desktop Metal

TCT Magazine

Nano Dimension is to acquire all outstanding shares of Desktop Metal for between $135–183 million, subject to the approval of Desktop Metal stockholders, regulatory approvals, and certain termination rights.Read More

Siemens Loses Longtime CNC Asset Randy Pearson

Gear Technology

The Siemens Machine Tool Business sadly announces the death of Randy Pearson, 70, on May 21, 2024, in Reno, Nevada, following a long battle with lung cancer. Randy had recently retired after more than 20 years with Siemens, where he served as dealer support manager and much more.Read More

Lithium-Ion Battery Components Are at the Nexus of Sustainable Energy and Environmental Release of Per- And Polyfluoroalkyl Substances

Nature Communications

Lithium-ion batteries (LiBs) are used globally as a key component of clean and sustainable energy infrastructure, and emerging LiB technologies have incorporated a class of per- and polyfluoroalkyl substances (PFAS) known as bis-perfluoroalkyl sulfonimides (bis-FASIs). PFAS are recognized internationally as recalcitrant contaminants, a subset of which are known to be mobile and toxic, but little is known about environmental impacts of bis-FASIs released during LiB manufacture, use, and disposal.Read More

|  |

2024 Powder Metallurgy (PM) Design Excellence Awards Announced

Gear Technology

The winners in the 2024 Powder Metallurgy (PM) Design Excellence Awards competition, sponsored by the Metal Powder Industries Federation (MPIF), demonstrate outstanding examples of PM’s diversity and ability to meet critical requirements. From electric vehicles to medical implants, once again, parts fabricators have demonstrated PM’s versatility and unique ability to challenge competing technologies. These award-winning components use PM’s flexibility to push forward new concepts and process controls to demonstrate the inexhaustible range of PM’s capabilities.Read More

Shapeways Ceases Operations and Files for Bankruptcy

TCT Magazine

Shapeways has ceased operations and filed for bankruptcy “after considering all strategic alternatives.” The publicly listed company published a Form 8-K on July 2nd, 2024, detailing that it has filed a voluntary petition for relief under the provisions of Chapter 7 of Title 11 of the United States Bankruptcy Code. Filing for bankruptcy in the United States Bankruptcy Court for the District of Delaware, Shapeways has confirmed each of its subsidiaries have also ceased operations and filed for bankruptcy.Read More

Struggling With Falling Demand for Farm Equipment, Deere & Co. Announces Nearly 600 Layoffs

Associated Press

Deere & Co. is laying off nearly 600 workers as the farm equipment manufacturer deals with declining demand. Early in June, Deere announced that it was moving its skid steer and track loader manufacturing from a facility in Dubuque, Iowa to Mexico by the end of 2026. The company said that it was in the process of acquiring land in Ramos, Mexico to build a new factory.Read More

Power from Flower: Albanian Farm Plants Suck EV Battery Metal from Soil

Interesting Engineering

The growing popularity of electric vehicles has led to an increased demand for nickel. While mining more ore is one way to meet this demand, many startups are also turning to farming instead to address an industrial need with a much more sustainable approach.Read More

|  |