[please visit our sponsor]

Gear Heat Treatment Operator & Operations

August 6–8, 2024—Hotel Cleveland; Cleveland

This course provides the heat treat operator and operations team, the means to perform the heat treatment of steel gears in a manner that meets the AGMA and customer requirements in a safe and efficient manner. The course identifies the key requirements for proper processing. Sufficient metallurgical background is provided to allow the student to identify how this information relates to the required processing and properties of the gear.Register Now

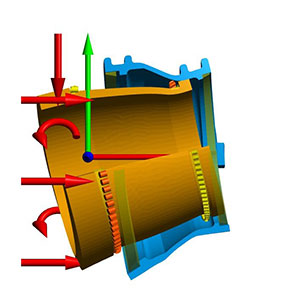

Emerging Tech Webinar Series - Convoloid Gearing: Case Studies with a New Type of Gear Technology

August 7, 2024—Live Online

Although new developments in gear technology such as surface finishing, new materials, new coatings, and others have meaningfully contributed to increases in gear drive system power density improvements, these increases have been relatively small, that is, approximately 1 to 3 percent annually at best. Convoloid gearing (computer optimized) versus involute (a mechanically based system) creates incremental improvement in gear drive system power density with ranges of the order of 15 to 20 percent over current design practice. This webinar will detail new design and rating procedures where (2) Convoloid gear box design variants are compared to a well-established industrial gearbox (the baseline) for several critical gear rating and surface condition factor parameters resulting in power density increases of 15 to 20 percent.Register Now

Reverse Engineering

August 14-15, 2024—Live Online Course

Reverse engineering a gear system is a not too unusual task and in many, but not all, cases the process goes well, thus it is easy to become complacent. It is important, however, to fully understand the process and the best practice procedure for reverse engineering a gear system. Failure to fully follow best practice can result, at best, in an unhappy gear user, but in the worst case it can lead to very expensive, time-consuming and reputation damaging litigation. This course will examine the basic types of reverse engineering projects (e.g. upgrading an existing system to increase power or extend operating life or improve noise level; replacing gear that has simply reached the end of its otherwise successful useful life; emergency, short term, interim gear replacement resulting from an unexpected failure; responding to a system that is not providing acceptable performance, etc.).Register Now

How to Read and Interpret a Gear Inspection Chart

August 20, 2024—Live Online Course

This half-day online seminar is intended to provide you with a thorough understanding of the information contained within a typical gear inspection report. Specifically, we will look at the contents and meaning of the information contained within the gear charts, as well as the techniques used by the gear measurement system to assess gear quality. An explanation of basic gear measurement techniques, how measurement equipment and test machines implement these techniques, and how to interpret the results from these basic measurements will be covered. We will also discuss how to interpret the results and what corrective actions may be considered if the quality of a particular gear is unsatisfactory.Register Now

Design Basics for Spur and Helical Gears

September 10, 2024—Live Online Course

Learn how to develop and understand customer gear drive application specifications and target performance expectations. Review, calculate and select basic gear terminology variables and design parameters which define tooth bending and contact rating safety factors on two real-life examples. Learn how to optimize gear fatigue Safety Factors for a given target design life and fit new gear designs and ratios into existing center distance using profile shift. Use commercially available software to develop gear geometry factors, calculate and optimize gear set power density and performance. Review common gear failure modes if the design or final accuracy does not meet application requirements.Register Now

[please visit our sponsor]

Smart Move: Save Big with a CNC Recontrol

It’s hard to stay competitive with older gear machines using outdated controls. New machines are often too costly a solution – and you’ll wait months for delivery. The smart move is an MTB Recontrol. In just three months, and for a relative fraction of a new machine investment, we can recontrol most CNC gear machines – and bring them up to profitable new performance levels.

Learn more. Download the Whitepaper

GMTA – Systems solution provider for the gear industry

New Profilator S300 machine

- Flexible modular machine platform (skiving, hobbing, pointing, cycloidal milling, chamfering and deburring)

- Single or Twin spindle platforms available

- Optional tool changer turret for maximum machining flexibility

- Siemens One with conversational part programming

- Easy setup and access due to open walk-in work area

Read More

Unlocking infinite possibilities through efficient transmission with WORM drives

WORM drives enable precise motion, excel in tight spaces, and meet high torque demands in robotics, conveyors, and automotive sectors.

As industries evolve, they stand as enablers of progress, unlocking infinite potential with reliability.

CHUN YEH GEAR can manufacture - Max. Module: M10, Accuracy Capability: DIN 1, AGMA 14, JIS 0.

Read More

Massive Machinery and Innovation at MINExpo International 2024

Power Transmission Engineering

MINExpo boasts 1,900+ companies involved in the global mining industry. Opening sessions allow the industry to come together to debate global challenges, market fluctuations and the future of mining. Resources include exploration, mine site development, open pit mining, underground mining, smelting and refining, processing and preparation and reclamation. Here’s a sample of the companies exhibiting and the products/technologies they will be featuring in Las Vegas from September 24–26, 2024.Read More

Efficient Maintenance Saves Thousands in Gearbox Replacement Costs

Reliable Plant

A limestone transport belt conveyor gearbox, which had been running smoothly for four years with normal vibrations below 2 mm/sec, began to show increased vibrations and jerks. The mechanical inspector reported the gearbox’s behavior had changed, and within three weeks, the vibration at the gearbox input shaft vertical position surged to 14 mm/sec, accompanied by abnormal noise. This situation was critical as the gearbox fed two raw mills, and a spare gearbox was unavailable for several months.Read More

Preventing Corrosion in Gears

Gear Technology

Gear Technology recently had the opportunity to sit down with Thomas White, Marketing Manager for Northern Technologies International Corporation, whose ZERUST line of corrosion prevention solutions includes specialized packaging, testing and comprehensive corrosion management services. We wanted to find out more about what causes corrosion in manufactured parts and whether there were any special considerations specific to gears, splines and shafts. Here’s a transcript of our conversation.Read More

|  |

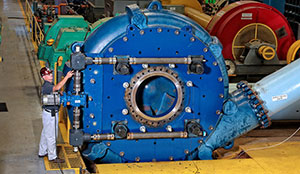

Pumps Range Addresses Hard Rock Mining Wear Issues

Engineering News

The GIW range of slurry pumps from the South African division of pumps and valves maker KSB Pumps and Valves is designed to ensure optimal wear performance in the harsh conditions found in hard rock mining applications, reports mining market area manager Jacques Pretorius.Read More

High Level Automation and System Integration

Power Transmission Engineering

Mechanical and electronic engineering continues to play a significant role in the changing transportation landscape. Areas such as connected vehicles, autonomous driving, new components and software-designed modules will push the latest EV technologies for the next ten to 15 years. Mechatronics will play a pivotal role in these advancements.Read More

MESYS Version 06/2024 Now Available

Gear Technology

A new version of the MESYS shaft and rolling bearing analysis software including new functionality is available. The bearing analysis software allows the calculation of the load distribution within the bearing and bearing life according to ISO/TS 16281 and it is integrated in a shaft system calculation with additional possibilities like modal analysis, strength calculation for shafts and interfaces to gear calculations.Read More

|  |

Zero-Max Celebrates 75 Years of Innovation

Power Transmission Engineering

Becoming an industry-leading manufacturer of motion control and power transmission components came quickly for Zero-Max by being responsive to customer’s needs with innovative products and exceptional service. Its first product was a unique Mechanical Variable Speed Drive that solved application challenges in varied industries, with many of these drives still in use 75 years later.Read More

NASA Awards Launch Excitement for STEM Learning Nationwide

NASA

NASA awards inspire the next generation of explorers by helping community institutions like museums, science centers, libraries, and other informal education institutions and their partners bring science, technology, engineering, and mathematics (STEM) content to their communities. NASA’s Next Generation STEM project has expanded the Teams Engaging Affiliated Museums and Informal Institutions (TEAM II) program to include a new tier of funding and provide even more opportunities to informal educational institutions across the country.Read More

Robot-Packed Meals are Coming to the Frozen-Food Aisle

MIT Technology Review

Chef Robotics, a San Francisco–based startup, has launched a system of AI-powered robotic arms that can be quickly programmed with a recipe to dole out accurate portions of everything from tikka masala to pesto tortellini. After experiments with leading brands, including Amy’s Kitchen, the company says its robots have proved their worth and are being rolled out at scale to more production facilities. They are also being offered to new customers in the US and Canada.Read More

GKN Automotive Focuses on Powertrain Developments for EVS

Power Transmission Engineering

As the world shifts towards sustainable energy solutions, the demand for electric vehicles (EVs) continues to increase, and at pace. This transition impacts the priorities of those throughout the industry—from OEMs to suppliers—as traditional automotive components are being replaced by electric motors, battery systems, power electronics, and thermal management systems.Read More

|  |