[please visit our sponsor]

Intelligent Manufacturing Augmentation: The Copilot Model for Generative AI

September 4, 2024—Free Emerging Tech Webinar

This AI webinar—presented by Softura—is tailored specifically for AGMA industry professionals. Discover how these advanced technologies can enhance precision, efficiency, and innovation in your manufacturing processes AND your front & back office. Learn about real-world applications, success stories, and practical strategies to stay ahead of the competition. Don’t miss this opportunity to transform your operations and lead the industry with the power of AI-driven automation.Register Now

Design Basics for Spur and Helical Gears

September 10—Live Online Virtual Training

Learn how to develop and understand customer gear drive application specifications and target performance expectations. Review, calculate and select basic gear terminology variables and design parameters that define tooth bending and contact rating safety factors on two real-life examples. Use commercially available software to develop gear geometry factors and calculate and optimize gear set power density and performance.Register Now

Basic Training for Gear Manufacturing

September 16–20, 2024—AGMA National Training Center; Chicago

Learn the fundamentals of gear manufacturing in this hands-on course. Gain an understanding of gearing and nomenclature, principles of inspection, gear manufacturing methods, and hobbing and shaping. Utilizing manual machines, develop a deeper breadth of perspective and understanding of the process and physics of making a gear as well as the ability to apply this knowledge in working with CNC equipment commonly in use.Register Now

Condition Monitoring

Oct–16–17, 2024—Live Online Course

In this course we will examine each of these questions and the interrelation of each with a primary focus on how this information can be used to define the actions required to keep the gearbox running properly and to allow maintenance planning. There are many parameters that provide information about the condition of an operating gearbox, some are lubrication centric while others are operationally centric. Each parameter, individually and in combination, can provide insight into the condition of the gearbox and its individual components.Register Now

Gearbox CSI: Forensic Analysis of Gear & Bearing Failures – Useful Tools for Optimizing Gear Design

Oct–22–31, 2024—Live Online Course

A good understanding of individual failure modes and the failure scenarios that led to the actual system failure is an essential skill to designing gear/bearing systems that will operate properly for their full design life. In this course, we will define and explain the nature of many gear and bearing failures and we will also discuss and describe various actual failure scenarios. In addition, a detailed primer on bearing technology prefaces the failure scenario discussions. You will gain a better understanding of various types of gears and bearings.Register Now

[please visit our sponsor]

Smart Move: Save Big with a CNC Recontrol

It’s hard to stay competitive with older gear machines using outdated controls. New machines are often too costly a solution – and you’ll wait months for delivery. The smart move is an MTB Recontrol. In just three months, and for a relative fraction of a new machine investment, we can recontrol most CNC gear machines – and bring them up to profitable new performance levels.

Learn more. Download the Whitepaper

Efficient transmission, Infinite Possibilities - WORM drives

Worm drives achieve a balance between precision and power. The teamwork between the worm and worm gear makes a strong partnership. Compact and efficient, this pair exemplifies the outstanding quality of worm drives. CHUN YEH GEAR can manufacture - Max. Module: M10, Accuracy Capability: DIN 1, AGMA 14, JIS 0.

Read More

AGMA Launches Redeveloped On-Demand Workforce Training Series Courses

The American Gear Manufacturers Association (AGMA) has redeveloped its on-demand Workforce Training Series. The redeveloped courses have been modernized to make them more accessible with updated materials to incorporate new and emerging technological advances.

Read More

Holistic Assessment of Drive Systems with Gears, Shafts and Bearings Using Measured Torque-Speed Data

Power Transmission Engineering

Verification of a drive system should include all main elements of the system, which are gears, bearings, shafts, and depending on the application other parts such as screws, couplings, and connections. Gears are clearly the most complicated parts for verification, but in many cases, a gearbox failure has its origin in a shaft or bearing failure.Read More

Role of Forging in Supply Chain Resilience

Gear Technology

The success of manufacturing critical components, such as ship shafts, gears, artillery or adaptor plates/rings, depends on their design and how well that design can be translated into a tangible, cost-effective, high-quality product. This is where Design for Manufacturability (DFM) comes into play. The significance of DFM rests in the forging process's role in creating a robust and resilient supply chain.Read More

Embracing Electric Actuators for Mining Equipment

Canadian Mining Journal

In dynamic fields like mining, construction, and other heavy industries, the relentless pursuit of efficiency and sustainability has driven significant technological shifts, with mobile equipment electrification being one of the most notable. While mining equipment manufacturers have excelled in developing and deploying electric powertrains, one key area that remains to be decarbonized is hydraulics.Read More

|  |

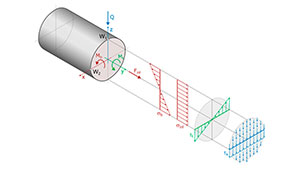

Space-Based Solar Power Gets Practical

IEEE Spectrum

The idea has always been, well, out there. What if we put giant arrays of solar panels in space, where the sun never sets and clouds never form, to collect limitless electricity to beam to Earth? For a world badly in need of clean, continuous energy, space-based solar power seems perfect, pure, ideal—until you begin to consider the cost, complexity and risk of assembling city-sized arrays high in Earth orbit.Read More

Pratt & Whitney Advances the use of Metal Additive Manufacturing with its F135 and TJ150 Engines

Metal AM

US defense contractor Pratt & Whitney, a Raytheon Technologies business, headquartered in East Hartford, Connecticut, informed Breaking Defense that it intends to use Additive Manufacturing (AM) for the F135 engine, which powers Lockheed Martin’s F-35 Joint Strike Fighter.Read More

Timken Agrees to Acquire CGI Inc.

Power Transmission Engineering

The Timken Company has agreed to acquire CGI Inc., a Nevada-based manufacturer of precision drive systems serving a broad range of automation markets with a concentration in medical robotics. The deal is subject to customary closing conditions, including regulatory approval, and is expected to close in the third quarter.Read More

|  |

Understanding Bevel Gear Grinding

Gear Technology

The world of bevel gear grinding is a complex topic. How do you determine which grinding and dressing parameters to select for a desired surface finish? What type of grinding wheel should be used? What type of dresser should be used? How do all these factors affect the gear noise and quality levels? These are some questions that will be addressed in this article.Read More

Why Emerging Companies Shouldn’t Be Intimidated by Warehouse Automation Solutions

Inc.

While larger companies regularly utilize robots in retail and e-commerce order fulfillment--and some even have fully robotic warehouse solutions--investing in large-scale warehouse automation can often be cost-prohibitive for smaller businesses. But as many of these technologies grow more commonplace throughout the supply chain, certain automation solutions have emerged as attractive, economic solutions that can boost efficiency and productivity for growing companies.Read More

The Rise of Robotics in the Energy Sector

Oilprice.com

Innovations in robotics have greatly supported energy operations in recent years, with robots now aiding both fossil fuel and renewable energy production. The use of robotics in oil and natural gas operations has made the sector significantly safer, reducing the need for personnel to work in dangerous situations.Read More

|  |