Gear Industry News November 21, 2023

[please visit our sponsor]

AGMA Updates

AI Steered, Safety Geared: AI’s Voyage with Gear Manufacturing

December 6—Emerging Technology Webinar

Artificial Intelligence (AI) is changing the game in gear manufacturing, bringing in intelligent automation, better decision-making, and insightful data analysis. However, it could be smoother sailing as the rise of AI also opens doors to clever cyberattacks, which can be a risk to the manufacturing process. In this presentation, we’ll dive into the good, the bad, and the ugly of AI for the gear manufacturing industry and share practical steps to enjoy the benefits of AI while keeping the bad guys at bay. Presentation by James R. McQuiggan, CISSP, SACP.Register Today

Involute Spline Design and Rating—Winter

January 17–18—Live Online Course

This course will address both geometry and rating of involute splines of various types. The types of spline joints and their applications will be discussed. Spline configuration variations, including half-depth, full-depth, and special function designs, will be addressed. Both fixed and flexible spline configurations will be examined in terms of usage and design. Lubrication methods, including grease, oil bath, and flowing oil, as well as coatings appropriate for various spline applications, are examined. Shear and compressive stress rating methods are discussed with analysis methodology presented in both equation and graphical methodology via various rating charts.Register Today

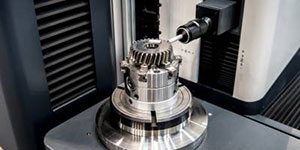

Analytical Gear Chart Interpretation—Winter

January 23—Live Online Course

This course is an introduction to the methodology of analytical gear inspection and the evaluation and interpretation of the resulting data. The application of this information to identify and correct manufacturing errors will begin to be explored. Additionally, it reviews chart interpretation and applies inspection data to understand the causes and cures of manufacturing errors. Many chart examples are used to understand cause and effect.Register Today

Gear Materials

January 30–February 1 & February 6–8—Live Online Virtual Training

Learn what is required for the design of an optimum gear set and the importance of the coordinated effort of the gear design engineer, the gear metallurgist, and the bearing system engineer. Investigate gear-related problems, failures and improved processing procedures.Register Today

[please visit our sponsor]

Industry News

New Digital Simulation Tool for Gear Machining Saves Time And Money

University of Waterloo

Researchers from University of Waterloo’s Faculty of Engineering—Precision Controls Laboratory, led by Dr. Kaan Erkorkmaz, have developed software to simulate and optimize the gear cutting process to save time and money for large- and medium-sized manufacturing. The new software, called ShapePro, simulates gear cutting by predicting the complex chip geometry and cutting mechanics (e.g., machining forces, tool/workpiece deflections) in three of the major gear machining processes: shaping, hobbing, and power skiving. With these predictions, the software enables accurate analysis, as well as automated or manual optimization of the machining process parameters.Read More

Neugart Extends Economy Series Gearboxes by Smaller Frame Sizes

Design World

Neugart responds to the desire of many machine builders for more compact, lighter servo drives with two corresponding gearboxes: The newly developed PLQE040 and PLFE055 extend the proven Economy series PLQE and PLFE by two smaller frame sizes and round out the corresponding portfolio downwards. The two new gearboxes are based on the millions of Economy series units utilizing spur gearing technology from Neugart.Read More

SDP/SI Passes Recertification AS9100 and ISO 9001 Quality Management System Audit

Gear Technology

Stock Drive Products/Sterling Instrument (SDP/SI), a Designatronics, Inc. company, completed and passed its recertification AS9100:D and ISO 9001:2015 quality system audit. The audit, conducted by Intertek over 5 days, certifies SDP/SI’s quality management system conforms to AS and ISO standards. The in-depth AS and ISO recertification audit takes place every three years and is performed by an unbiased third party. The audit team reviews and verifies policies, procedures, and documentation establishing compliance with AS and ISO requirements.Read More

|  |

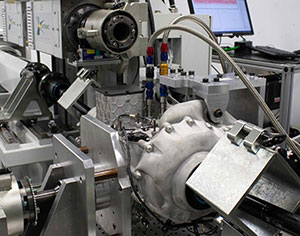

Tech Insider: Czinger 21C Additive-Manufactured Transmission

Automotive Powertrain Technology International

“The idea of doing the gearbox case has been on the agenda for about four years,” reveals Czinger chief engineer Ewan Baldry. In the early days of the project, though theoretically feasible, the footprint of the metal AM machines then in use couldn’t accommodate a complete transmission casing. However, Baldry had confidence in the developments Divergent had underway: “We knew on the roadmap that we would be going to machines that would be capable of doing something for this kind of size.”Read More

SEW Eurodrive SA secures the group’s world-first X.e agitator gear units order

Cape Business News

After the recent X.e series agitator unit launch in July 2023, SEW-Eurodrive South Africa secured an order for nine units earmarked for the mining industry. The X.e agitator unit not only features a pressurized internal lubrication system that allows for continuous oil flow to all upper bearings and gears to ensure the units are well lubricated, but the unique labyrinth seal ensures protection from external particles that may damage the oil seals. Offering three sizes with various torque ranges and gear units, SEW-Eurodrive offers client-specific products all safely encapsulated inside the gearbox for client and product protection.Read More

U.S. Offshore Wind Power Development in Turmoil

Environment News Service

Siemens Gamesa Renewable Energy, the European supplier that leads the global market for offshore wind turbines, has suspended plans to build a US$200 million turbine blade factory at Virginia’s Portsmouth Marine Terminal, a major container port. Citing problems meeting “development milestones,” Siemens Gamesa confirmed Friday that at this time it will not continue to develop the 80-acre manufacturing site first announced in October 2021.Read More

|  |

Starrett Hosts Successful Manufacturing Day for Students, Community

Gear Technology

The L.S. Starrett Company, a leading global manufacturer of precision measuring tools and gages, metrology systems and more, announced it opened its doors to students and the community on October 6th this year from 10:00 a.m.–2:00 p.m. for Manufacturing Day at Starrett Corporate Headquarters, located at 121 Crescent Street, Athol, MA. Manufacturing Day activities nationwide were sponsored by the National Association of Manufacturers (NAM), an organization that works for the success of more than 12.8 million men and women who make things in America.Read More

Marshall Islands to Get Wind-Powered Solution to Help Decouple from International Bunker Prices

TradeWinds

The vessel’s sail system has been designed by German naval designer and test basin owner HSVA, adapted from a traditional Indonesian sail design. The goal is for the vessel to achieve a service speed of approximately 12 knots under sail and around 7 knots when utilizing a small onboard engine. While the propeller and engine will be used for slow-speed maneuvering such as in port or in times of no wind, the propeller has been designed to act as a turbine to generate electricity for the ship’s electrical system via a hybrid gearbox and generator.Read More

MTC’s License to Thrill

Develop3D

Using a GE Arcam 3D printer, a small-scale particle accelerator fires electrons at the powder bed under vacuum, in order to melt metal material, instead of using a direct laser weld. Cost-effective, this approach produces parts with a coarser surface finish, but ones that are less prone to warping and thermal stress. Using their fancy machine, the Qs in the MTC lab were able to print parts for the Oxford Brookes Formula Student racing team. The uprights that were printed delivered a 50 percent weight savings and enabled the gearbox to produce more than 300 Nm of torque per wheel.Read More

|  |

Kohler Energy Accelerates Clean Energy Vision & Expands Offering with New Hydrogen Solutions

Power Transmission Engineering

Kohler Energy recently announced a new hydrogen KDI engine and its first-ever hydrogen fuel cell power system, expanding an ever-growing portfolio of clean energy solutions during the Agritechnica trade show in Hanover, Germany on November 13. Building off the recent announcement of Kohler Co. establishing Kohler Energy as an independent company, this news further accelerates Kohler Energy’s strategy to provide the broadest range of clean energy and hydrogen-ready solutions for off-highway equipment and standby and prime power applications for residential and industrial solutions from 20 kW to 5 MW+.Read More

|  |