[please visit our sponsor]

Design Basics of Spur and Helical Gears

January 28—Live Online Course

Learn how to develop and understand customer gear drive application specifications and target performance expectations. Review, calculate and select basic gear terminology variables and design parameters which define tooth bending and contact rating safety factors on two real-life examples. Learn how to optimize gear fatigue Safety Factors for a given target design life and fit new gear designs and ratios into existing center distance using profile shift.Register Now

Analytical Gear Chart Interpretation

January 29 —Live Online Course

This course is an introduction to the methodology of analytical gear inspection and the evaluation and interpretation of the resulting data. The application of this information to identify and correct manufacturing errors will begin to be explored. Additionally, it reviews chart interpretation and applies inspection data to understand the causes and cures of manufacturing errors. Many chart examples are used to understand cause and effect.Register Now

Loaded Tooth Contact Analysis

January 30—Live Online Course

Evaluation of loaded tooth contact and development of tooth modifications using commercially available software to improve and apply a realistic load distribution factor Km in gear rating calculations and reduce transmission error. Two real life gearing examples will be reviewed in the course, one will have a cantilever mounted pinion, the other a shaft pinion straddled non-symmetrically by bearings.Register Now

Steels for Gear Applications

February 11–13—Live Online Course

Gain a basic understanding of steel and its properties. Learn to make use of steel properties in an application and understand the potential that different steel and heat treatment options can offer. Explore how performance of the material depends on how the steel is produced.Register Now

[please visit our sponsor]

Save Big on Fine Pitch Gear Production

You’ll pay a premium for the ‘household’ brandnames – and fine pitch gear production doesn’t come cheap. Machine Tool Builders has brought economical, worldclass performance to fine- and super-fine pitch gear production with HAMAI horizontal hobbing, SMG vertical hobbing, and Burri combination profile and generating grinding machines. Various capacities, automation and other options to choose from.

Contact MTB Today

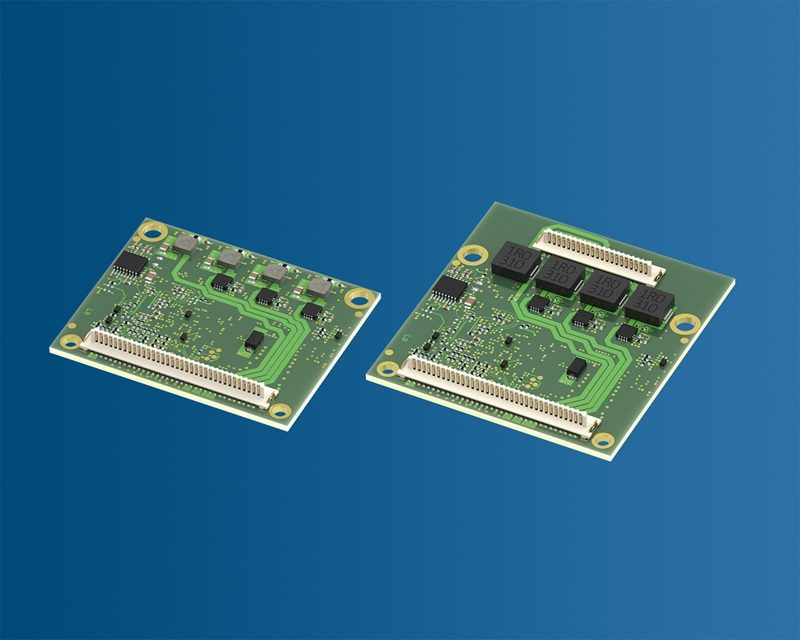

Faulhaber Offers Motion Controller with Four Different Motor Technologies

A motion controller with even more possibilities: With the new MC 3602 B and MC 3606 B motion controllers, the selection and commissioning of drive systems is now even simpler. With the compact MC 3602/06 B, DC-motors, brushless DC-motors and linear motors can be operated with the typical position encoders as servo drive in accordance with CiA 402.

Read More

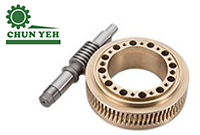

With the WORM drives, everything is high efficiency

Worm drives, the most compact gear system; provide high-ratio speed reduction and greatly increase torque. To be effective, it’s crucial that they are manufactured with high-quality standards to ensure all requirements are precisely met. CHUN YEH GEAR can manufacture - Max. Module: M10, Accuracy Capability: DIN 1, AGMA 14, JIS 0.

Read More

Electromechanical vs. Hydraulic: A Linear Motion Case Study

Power Transmission Engineering

There’s a delicate balance in the constant evolution of today’s assembly line. Once dominated by hydraulics, manufacturing floors are incorporating a growing number of electromechanical solutions to supplement legacy hydraulic components, particularly in lower force, linear motion applications.Read More

Win the War for Tech Talent

Fast Company

Companies hiring tech talent are coming face to face with a new reality—economic issues are placing pressure on them to do more with fewer workers, but technology is evolving faster than their talent pipelines often can.Read More

North Carolina Microgrid EV Charging Hub is a Model for Fleet Electrification, Duke Energy Says

Utility Dive

Duke Energy, working with electric vehicle infrastructure developer Electrada, has launched a “fleet mobility microgrid” in Mount Holly, North Carolina, that the utility said Thursday is a model for fleet electrification solutions.Read More

|  |

Teleo Wants to Help the Robotics Industry Reach its ‘ChatGPT Moment’

TechCrunch

Teleo describes itself as a construction robotics startup, but its mission is bigger than automating heavy equipment like excavators and tractors. Today, Teleo’s retrofitted machinery allows its customers to operate their existing fleets semi-autonomously. In the future, the startup sees the data it collects as a key enabler for the robotics industry to reach its “ChatGPT moment.”Read More

Robot Adoption in Manufacturing Hits New Record

Engineering.com

Robot adoption in factories around the world continues soar, according to a new report by the International Federation of Robotics (IFR). The World Robotics 2024 report shows the new global average robot density reached a record 162 units per 10,000 employees in 2023, more than double the 74 units measured in 2017.Read More

More Than Maintenance: The Critical Role of Balancing in Rotating Equipment

The Manufacturer

Rotating machines—turbines, pumps, fans, and motors—form the backbone of modern industry, driving processes across energy generation, aerospace, pharmaceuticals, and automotive manufacturing. In an era where precision, efficiency, and reliability define industrial success, the performance of rotating equipment is non-negotiable.Read More

|  |