[please visit our sponsor]

Setting the Wayback Machine

I have often touted the Gear Technology archives as your ready source of reliable information. A recent question was resolved mid-conversation by the caller logging in and typing in a few key words. For all the problems the Internet causes, this instant information feature makes up for it.

I have often touted the Gear Technology archives as your ready source of reliable information. A recent question was resolved mid-conversation by the caller logging in and typing in a few key words. For all the problems the Internet causes, this instant information feature makes up for it.

Gear Nitriding in Vacuum

Vacuum gas nitride processing from Solar Atmospheres can significantly increase the fatigue strength and service life of your parts. Benefits include case depths up to 0.025” and improved wear and anti-galling properties due to a 40 - 70% increase in surface hardness. Corrosion resistance is increased through nitrogen-enrichment.

Read More

Easy Quality Bevel Cutter Builds

New 500CB makes it easy to achieve fast, high quality bevel gear cutter builds with less effort than ever before. Let us show you how...

Read More

The KAPP NILES KX 260 DYNAMIC – A design offered nowhere else.

The KAPP NILES KX 260 DYNAMIC features a patented inverted spindle which facilitates optimum productivity for mass production of external planetary gears. Automated work-arbor change and verification as well as semi-automated grinding worm change are highlighted. Save on set-ups, save on floor space, save on investment.

KAPP NILES KX 260 VIDEO

Read More

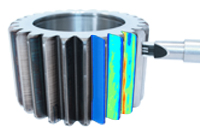

Only the Klingelnberg can – measure smooth surfaces in rough conditions

Measuring surface roughness as part of gear measurement delivers reproducible results in accordance with standards. Only on a Klingelnberg P-Machine can you measure gear surfaces starting from module 0.9 mm (DP 29) using the full CNC-Axis movement – even on the shop floor! Since surface roughness measurement is part of the measuring cycle no setup time is needed any more.

Read More

CASE STUDY DOWNLOAD: Nital Etch vs. Barkhausen Noise

Learn how customers increased their analysis accuracy and repeatability, and cut costs by reducing scrap and eliminating the need for chemical disposal. This non-destructive testing method for grinding burn detection and heat treat defect detection improved product quality and resulted in significant cost savings.

Read More

Gear Expo 2017 – The Drive Technology Show

Join thousands of drive technology experts and power transmission professionals for three days of industry-related events.

Gear Expo is where gear buyers, end users, manufacturers, and engineers from power transmission industries come to discover innovative technologies, network, and build relationships.

Read More