Following in a Giant's Footsteps

By Charles D. SchultzThere are no self-made men or women in the gear trade. I frequently told my children that “all generalizations are wrong” yet I will stand by that opening sentence.

Why? Because we work in a trade so old that no one can claim to have “invented” it. It seems to have popped up in several places with a surprising level of sophistication while lingering on in a relatively primitive state for a very long time.

Master Gears and Gauges from Star SU

Star SU offers a wide range of precision gauges for measurement, calibration, setting, and correction purposes including; master gears, setting masters, and rolling gears. Learn more about the entire offering:

Read More

Gleason 2700AR system automates larger gear load/unload

With the new Gleason 2700AR, users can automate the handling of larger gears with a ‘plug-and-play’ solution that’s both fast and much more economical than custom solutions. Precious time, the potential for human error, and the possibility of operator injury are all greatly reduced. Now, the operator can be available for other, more important tasks, while the 2700AR does all the heavy lifting.

Read More

ECM Robotics Integration & Automated Solutions

ECM Robotics offers your manufacturing the best heat treat experience by mastering the latest technology and industrial innovations. We utilize virtual reality for concept rendering, 3D printers for prototyping, and 3D simulations to validate cycles. Learn more about fully-automated process control and all-inclusive robotic packages by contacting ECM today! 262.605.4810 www.ecm-usa.com

Read More

Adding nitriding/FNC capacity? Experience matters.

When it comes to nitriding furnaces, our best-in-class equipment designs, over 100 units built, an industry-leading, efficient and accurate process for controlling nitriding potential, and vertical or horizontal configurations make SECO/VACUUM the best choice for gas nitriding.

Click to Learn More

Hexagon Optimizes CMM Performance with Asset Management Software

Hexagon’s Manufacturing Intelligence division recently launched HxGN SFx | Asset Management, a cloud-ready software solution that helps manufacturers achieve operational excellence by offering easy access to real-time machine status and utilization reporting.

Read More

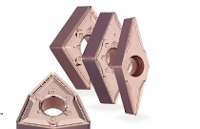

Ingersoll Offers CVD Coating for High Temp Alloy Finish Turning

Ingersoll announces a new CVD coating for high temp alloy finish turning. The TT3005 features a high abrasion resistant ultra-fine substrate, multi-layered CVD coating for very high wear resistance and predictable, machining stability.

Read More