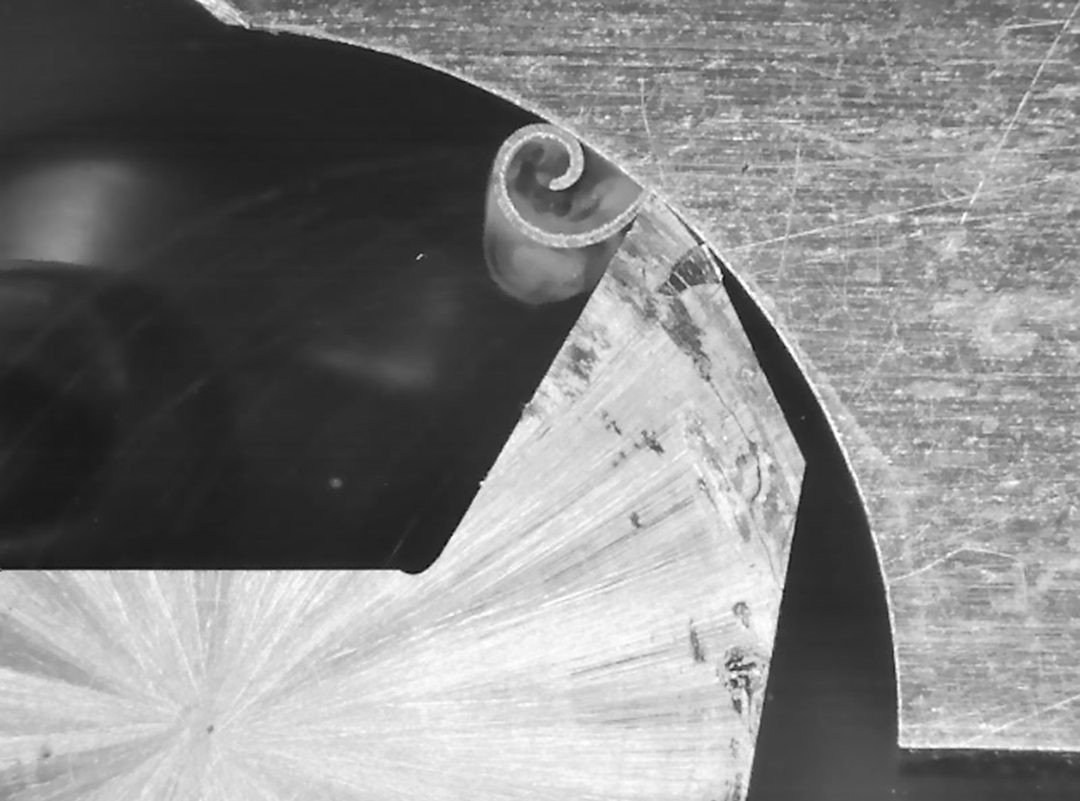

Blaser Examines Every Chip in Detail in an Innovative Series of Tests

The macro high-speed recordings are impressive: Viewed in slow motion, a carbide milling tool removes a perfectly shaped brass chip. The Blaser Synergy 735 metalworking fluid becomes cloudy around the curling chip—exactly where the heat is greatest. It leaves an oil-like phase and thus forms an even more effective lubricating emulsion. In an extensive series of tests in the in-house Technology Center, the metalworking fluid experts from Blaser Swisslube analyze machining processes down to the finest detail. The principle: To achieve better metalworking fluids faster through expertise and data.

Three New AGMA Publications

AGMA is pleased to announce the publication of three new documents including AGMA 955-A22, Guidance for Industrial Gear Lubrication written by the AGMA Lubrication Committee. AGMA 955-A22 is a guide for gear designers and manufacturers in the selection of suitable commercially available liquid lubricants for open and enclosed gear drives.

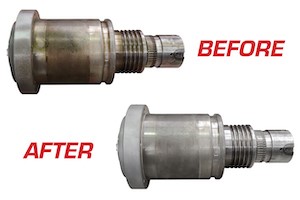

Spindles Repaired and Balanced for Higher Performance

PDS provides better-than-new spindle repairs for precision machining applications. Two-step balancing yields; minimized vibration well within specs, properly dressed grinding wheel, optimal finish with eliminated part chatter marks and precision profile, waviness, size, taper, and roundness tolerances met. Standard delivery time is 3-5 days, with emergency service available.

Read More

The New SINUMERIK CNC from Siemens Becomes a Digital Native Machine Tool Control

With SINUMERIK ONE, the first digital native CNC, Siemens is driving forward digital transformation in the machine tool industry. The new controller works with software to create the machine controller and the associated digital twin from one engineering system and thus contributes to the seamless integration of hardware and software.

Read More

DMG MORI Updates Solar Panel System Project

In January 2022, it was announced that DMG MORI Manufacturing USA, Inc. (DMM) would be investing an estimated $3.4 million towards the installation of a 2,000 kilowatt (kW) solar panel system on the roof of its manufacturing site in Davis, California.

Read More