Experimental Evaluation of Wind Turbine Gearbox Structural Models Using Fiber Optic Strain Sensors

The main objective of this study is to perform an experimental evaluation of the structural model of a five-planet first planetary stage from a modern 6MW wind turbine gearbox. The FEM structural model comprises the rotor side housing, also known as the torque arm housing, the first stage ring gear and the transition housing between the first and second ring gear. Strain measurements on the outer surface of the ring gear obtained in a full load back-to-back test bench have been used to validate the structural model. Optical fiber strain sensors have been used because they offer a higher signal-to-noise ratio, are immune to electromagnetic interference, and allow a more straightforward installation because multiple strain sensors can be accommodated in a single fiber.

Krebs & Reidel Offer Premium Grinding Wheels with High Process Reliability

Serial production of large gears requires a high level of quality, excellence, and continuity in production. Emphasis is placed on maximum synergy between the grinding machine, the grinding process, and the grinding wheel. After several successful trials on various Klingelnberg Höfler Rapid grinding machines carried out by Krebs & Riedel with customers in their production facilities, Krebs & Riedel has received several large orders for grinding large gears from abroad and has introduced the new premium grinding wheels with high process reliability.

State of the Gear Industry

Gear Technology's annual State-of-the-Gear-Industry Survey is a valuable resource for the entire industry, helping us better understand the current economic position and outlook for companies manufacturing gears. The survey takes less than 10 minutes and results will be available in the January/February 2024 issue.

Finish in First

With its application versatility and flexibility, the Gleason 1200G Profile Grinding Machine is the ideal solution for fine finishing larger gears up to 1,250 mm diameter, delivering exceptional grinding performance for particularly large profile depths. For even larger gears, we have you covered:

more information

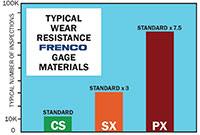

Frenco Offers Material Upgrade on INO-System Spline Gages

Euro-Tech Corporation in cooperation with Frenco, the precision specialist in gear & spline metrology, is offering a Free Material Upgrade for quotes between now and March 31, 2024.

Read More

Join Us For EV Automotive Transmission System Design

AGMA is hosting our EV Automotive Transmission System Design on April 23-25, 2024, in Ann Arbor, MI! For more information such as dates and times and registration deadline, click on the link below.

Register Now