Results of ISO/TS 6336-22 Evaluating Full Contact Zone

ISO/TS 6336-22 (Calculation of load capacity of spur and helical gears—Part 22: Calculation of micropitting load capacity) is the ISO technical specification containing a proposal for a calculation of risk of micropitting in gear sets. ISO/TS 6336-22 calculates a safety factor against micropitting by comparing the minimum specific lubricant film thickness to the permissible lubricant film thickness. Unfortunately, ISO/TS 6336-22 does not recommend a minimum safety factor. Rather, it is left to the engineer to compare the calculated results to a similar gear application.

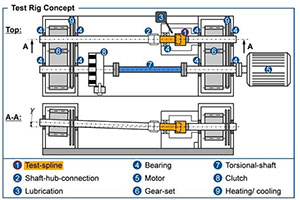

Test Rig for Crowned Spline Joints with Optimized Surface Treatments Under Misaligned Conditions

Factors influencing the load-carrying capacity of crowned spline joints include the material and heat treatment, the manufacturing history and single manufacturing steps, the final surface properties as well as the prevailing boundary conditions during operation, such as lubrication and temperature. Further investigations on the influencing variables on the spline-joint load capacity such as different materials, heat treatments, surface conditions and optimizations, lubrications, test temperatures, or microgeometries can be performed.

Bearing Show & Lubricant Expo North America in March

The Bearing Show is coming to North America, March 19 – 21 2024 at Huntington Place, Detroit, Michigan, co-located with Lubricant Expo. North America’s newest FREE exhibition and conference connects the evolving needs of bearing and lubricant end-users. Meet top companies exhibiting and hear from experts ranging across the whole industry’s ecosystem.

Register for FREE

The Differential Difference!

Introducing Gleason's new Coniflex® Pro Design and Manufacturing System for producing stronger, quieter, and more reliable e-drive differential gears in high volumes, for automotive, truck, bus and off-highway transmissions. It‘s the differential difference!

More Information

Join Us For EV Automotive Transmission System Design

AGMA is hosting our EV Automotive Transmission System Design on April 23-25, 2024, in Ann Arbor, MI! For more information such as dates and times and registration deadline, click on the link below.

Register Now