From the Archive - Big Gears: High Standards, High Profits

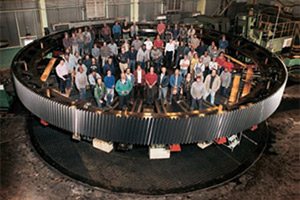

Natural resources—minerals, coal, oil, agricultural products, etc.—are the blessings that Mother Earth confers upon the nations of the world. But it takes unnaturally large gears to extract them.

From the Archive - Sizing Up Big Gears

The bar on quality standards continues to rise in the big-gear market even though many mining and off-highway projects are being cut or temporarily shut down. It’s a mad, mad world for large gear manufacturers, but if you’ve got the right technology, equipment and experience, it’s an industry segment that can be highly profitable.

State of the Gear Industry

Gear Technology's annual State-of-the-Gear-Industry Survey is a valuable resource for the entire industry, helping us better understand the current economic position and outlook for companies manufacturing gears. The survey takes less than 10 minutes and results will be available in the January/February 2025 issue.

Finish in First

With its application versatility and flexibility, the Gleason 1200G Profile Grinding Machine is the ideal solution for fine finishing larger gears up to 1,250 mm diameter, delivering exceptional grinding performance for particularly large profile depths. For even larger gears, we have you covered:

More Information

Master Gears and Gauges from Star SU

Star SU offers a wide range of precision gauges for measurement, calibration, setting, and correction purposes including; master gears, setting masters, and rolling gears. Learn more about the entire offering:

Read More

Efficiently Heat Treat Large/Oversized Parts with ECM Furnaces

Large workloads to 3m diameter x 3m high. Significantly reduce cycle times via higher temps (up to 1350°C). Increase production repeatability & efficiency with an ECM PFTH vertical oil quenching vacuum furnace to heat treat large parts/loads used in wind energy, mining, construction & agricultural applications. AMS2750 & CQI-9 compatible.

Read More

Trusted Gearing Solutions Since 1925 for Superior Performance

Since 1925, Cone Drive has delivered trusted double-enveloping worm gearing, renowned for high torque and superior performance. Our innovative designs ensure increased load capacity, reduced contact stress, and enhanced shock capacity. We specialize in worm, harmonic, cycloidal, and slewing solutions, providing reliable motion control for your most demanding applications.

Read More

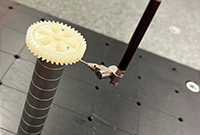

An Experimental Study on the NVH Performance of Plastic Gears

The following study presents an experimental methodology, employed to characterize the NVH behavior of plastic gears NVH in application-like operating conditions, presenting guidelines for material selection in terms of optimal gear NVH.

Read More

Join us for Design Basics of Spur and Helical Gears

AGMA is hosting our Design Basics of Spur and Helical Gears on January 28, 2025 online! For more information such as dates and times and registration deadline, click on the link below.

Register Now