From a Pencil Sketch to High-Tech Automation

Hetec GmbH, the Hessian machining technology specialist and supplier for tool, mold, and machine construction, has automated its production using the pallet handling system PHS 1500 Allround. The company almost exclusively manufactures individual parts and small series with long spindle running times and does not seem like a typical automation customer at first glance.

Hob High Quality Gears Without Shaving or Grinding

Would you like to be able to manufacture DIN 5 (or better) quality gears, pinions or splines without secondary gear finishing operations like shaving and grinding? Horizontal hobbing machines from EMAG Koepfer make this possible.

Let us reintroduce ourselves – experienced company with a new name

We are Nidec Machine Tool America, formerly part of Mitsubishi. Our machine tool heritage began in 1936, and continues with renewed dedication. For you, as a gear maker, we supply and support hobbers, shapers, shavers, skiving machines, and internal and external generating gear grinders. We do cutting tools, too.

Read More

Gear solutions for e-mobility by Liebherr

New drive technologies in electric mobility are changing the requirements for gears and therefore for the quality of the tooth flank surfaces. Liebherr has addressed this issue and refined various technological solutions for e-gearboxes. Generating grinding with dressing-free CBN grinding worms, for example, ensures a high degree of process reliability.

Read More

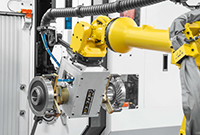

Precision Automation for Large Parts Handling

New Gleason Automation for load/unload of larger parts speeds throughput, optimizes the process flow – and lifts the burden off the machine operator. The AR Series uses advanced vision guidance to ID the part and ensure proper orientation before loading it into the machine, even if it arrives without precise location directly from dunnage. Easily integrated with pre-and post-processes such as part washing, deburring, inspection and marking.

See It In Action

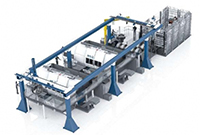

Advanced Automation for Heat Treat Production Lines

ECM ADVANCED AUTOMATION is the ideal solution for integrating & managing leading-edge robotic technology for your production line. Automate an existing or new heat treat system to assure a more reliable process from part sorting & load building to transport using AGVs in an ECM vacuum furnace or peripheral equipment.

www.ecm-usa.com

Read More

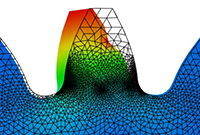

KISSsoft Includes FEM Calculations

FEM calculations have been included in KISSsoft on a long-term basis. For the calculation of planet carriers, gear body deflections and gear root stresses, FEM is used in order to better take into account complex geometric and/or loading conditions.

Read More

WFL Examines Evolution of Automation

The ever-greater variety of models has meant that transfer lines have tended to be replaced by flexible line chains or by individual cells with a variable material flow. Using intelligent software in combination with the relevant automation solutions not only enables workpieces to be loaded and unloaded but also means that machining centres can be set up fully automatically through the automatic replacement of tools and clamping devices.

Read More