Jergens Inc. Introduces New Compact Zero-Point System (ZPS) Modules and Pull Studs

Jergens now offers two new zero-point-system (ZPS) installation choices for compact, light-duty applications. SP140 and K02 pull studs utilize pneumatics and a mechanical spring in a small package. Together they offer quick-change solutions for vise or gripper jaws, electronic component manufacturing, packaging machines, medical technology, and automation.

Innovative Workholding Solutions for Gearing Technology

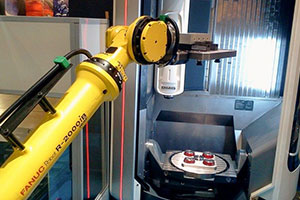

Workholding solutions increase throughput which generates uptime because they greatly reduce setup and changeover times. Operators can change workpieces in a highly repeatable manner which significantly increases the quality of the finished part. The primary function of streamlining production is to develop a workholding solution that optimizes the machining of multiple parts at once while maintaining tight tolerances.

Big Daishowa Highlights Four Workholding Tips

When it comes to securely and accurately situating material on a machine table, there’s often more than one way to get the job done. Are they all as precise or productive? Probably not, but they’ll get the part to the next step of the process. Everything will seem to be running as planned, but over time a scrap part here, or slow down there, and the cost of taking the easier or cheaper route adds up.

Workholding Changeover in 30 Seconds or Less

Modular and highly accurate clamping systems for vertical and horizontal machines, with mechanical or hydraulic actuation for all common machine spindles. Quik-Flex® Plus reduces changeover time to only 30 seconds or less. Available in standard and custom sizes to meet a wide range of applications. IOT Ready for DMC- and RFID-based networking.

Learn more

A New Dimension in Productivity

With Star SU Scudding® and skiving tools, quality meets speed with productivity 5 times faster than conventional gear cutting processes. Achieving surface finish and quality level far superior to traditional gear cutting technology, skiving allows the machining of internal or external gears/splines without the need of an undercut or groove.

Read More

PDS Offers Reliable and Cost-Effective Spindle Repair

PDS providesmanufacturers with better-than-new spindle rebuilds and repairs (within 1 micron) for precision machining applications. Since 1996, PDS’ factory-trained engineers and technicians have successfully rebuilt and globally supported more than 40,000 spindles. Save up to 50% of a new spindle replacement with PDS precision spindle repair!

Call us at 704-922-1206.

Or Visit Us

A clamping solution for optimum quality and short delivery times

Reduce downtimes and replace your clamping devices quickly with Liebherr’s segment clamping arbor SECLA. SECLA offers easy operation combined with maximum flexibility and short setup times. It is suitable for gear hobbing, shaping, skiving, and grinding. It also supports dry and wet machining and demonstrates high rigidity.

Read More

Efficiently geared, completely machined

More efficiency: Multitask machines from Pittler: Hollow ring gear skiving for planetary gears on a single machine?

No problem with Pittler SkiveLine. Do away with unnecessary special machines, become efficient, save production costs.

More effectiveness: The advanced cutting tools of the Pittler SkiveLine achieve an equivalent or even better result

compared to comparable solutions for gear cutting.

Read More

Southern Gear Announces HUBzone Certification

Southern Gear, a veteran-owned small business specializing in the manufacture of precision gears, is pleased to announce its certification as a Historically Underutilized Business Zone (HUBZone) business by the United States Small Business Administration (SBA).

Read More