Walter Introduces Automated Tool Production System

With the new Automated Tool Production (ATP) system, Walter now offers a comprehensive automation solution for cutting tools. ATP networks grinding, eroding and measuring machines from Walter, as well as upstream and downstream machines from other system partners in the production process.

Helios Welcomes Engineer Caeden Keith

Helios Gear Products (South Elgin, IL) proudly welcomes engineer, Caeden Keith. Caeden earned his degree in Mechatronics Engineering from Northern Illinois University (NIU). In this role, he collaborates with innovative manufacturers to develop custom cutting tools and work-holding automation solutions, driving excellence and innovation in the industry.

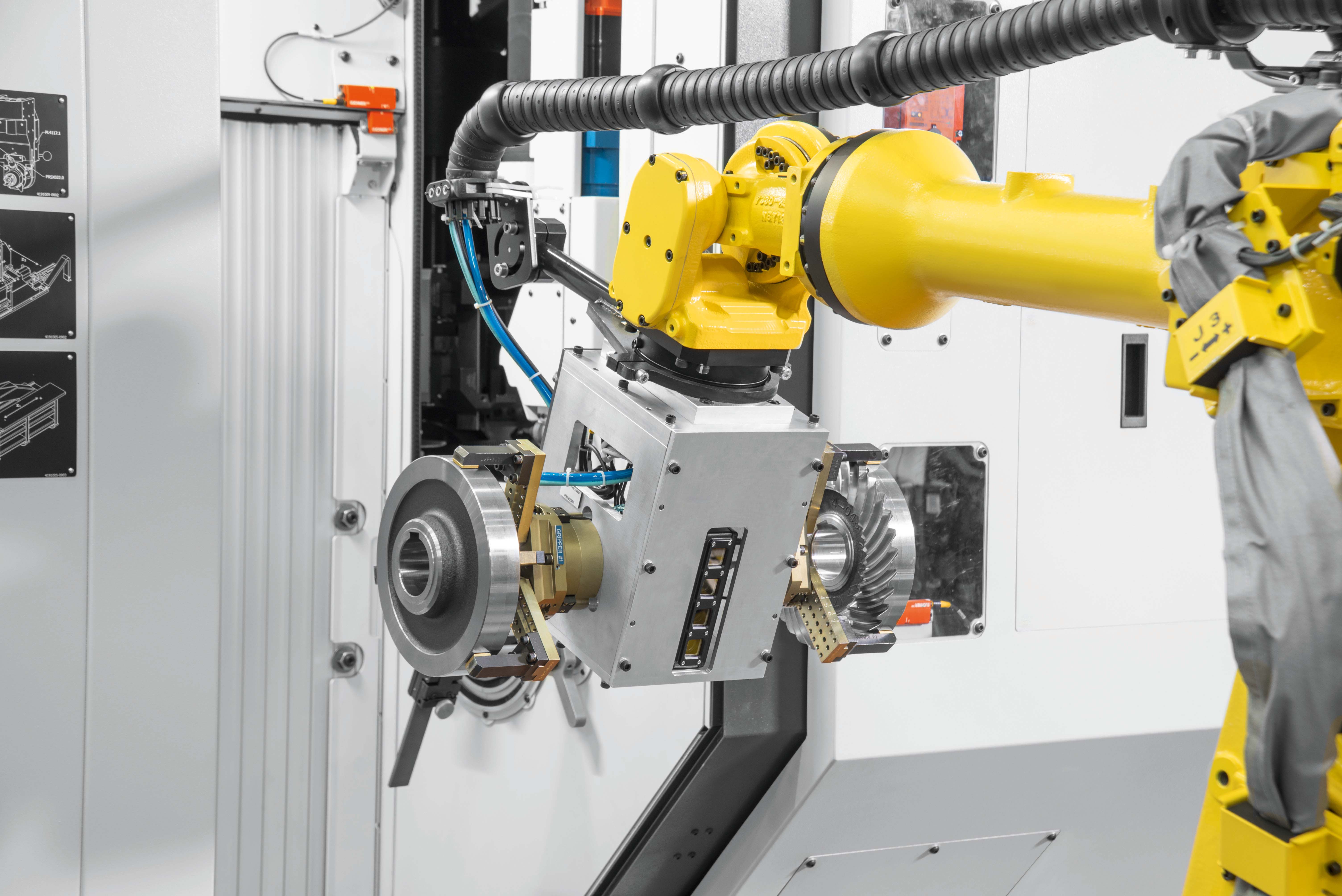

Precision Automation for Large Parts Handling

New Gleason Automation for load/unload of larger parts speeds throughput, optimizes the process flow – and lifts the burden off the machine operator. The AR Series uses advanced vision guidance to ID the part and ensure proper orientation before loading it into the machine, even if it arrives without precise location directly from dunnage. Easily integrated with pre-and post-processes such as part washing, deburring, inspection and marking.

See it in Action

Heat Treat Production Automation with ECM ROBOTICS

Streamline automating part sorting, workload assembly/disassembly & AGV/AMR transport with ECM ROBOTICS for your heat treat production line(s). Automate your operation (including washers, tempers, cryos…) with cutting-edge ECM technology for more consistent & efficient cycles, reduced labor costs & improved process stability. View an ECM AGV/AMR integration here: https://bit.ly/ECMRobotics.

Read More

Precision Motion Control Solutions for Over a Century

For more than a century, Cone Drive has been at the forefront of motion control technology, delivering precision solutions for a wide range of applications. Our team of expert engineers specializes in developing customized solutions tailored to meet your unique requirements.

Read More

Precision Grinding Solution for Gears, Worms & Splines

Grind spur, helical and crown gears, worms, splines, ball screws, rotors for air compressors and screws for hydraulic pumps on EMAG SU’s G 375 H. Its customizable options can grind high-quality workpieces up to 15” diameter and 34.5” long.

Learn More

DVS AMERICA presents PITTLER Skiving - MORE THAN YOU EXPECT

Discover a PittlerWorld - Simply more than Skiving.

From workshop-oriented user interface and software package to autonomic production with lower tool costs.

Read More

There is still time to get a new NIDEC gear machine

Limited time offer until March 9, 2025 – get the first preventative maintenance at No Charge and a full second year warranty at No Charge. Hobbers, gear shapers and gear grinders in stock for fast delivery – for example, GE25A Gear Hobber, S/N GE25420C5, manual load/unload. Call Scott Knoy today at 248-756-5017!

Read More

MAR – a landmark in the world of grinding machines

- Natural granite machine beds

- Electro spindles

- Torque rotating grinding wheel turret

- Ball screws or linear motor technology

- Glass scales

- Multi-wheel OD/ID platforms available

- Siemens or Fagor CNC controls

- Universal Torque workhead with integrated angular position control

- MAR designed simplified HMI

- Compact machine design

Read More

Join us for A Practical Approach to Managing Gear Noise

AGMA is hosting our Practical Approach to Managing Gear Noise on March 4, 2025 online! For more information such as dates and times and registration deadline, click on the link below.

Register Now

Reshoring In Action with C&B Machinery

C&B Machinery is proud to support the reshoring of a 30” Double Disc Grinding Machine for a major U.S. automotive manufacturer’s transmission plant. Originally installed in an overseas facility, this machine is now being brought back to the U.S., where it will be retooled, reautomated, and upgraded to enhance performance and efficiency for a Michigan-based production program.

Read More