|

Get the freshest updates on gear technology

|

|

|

|

| Visual Components Unveils Omniverse-Powered Virtual Application at NVIDIA GTC DC |

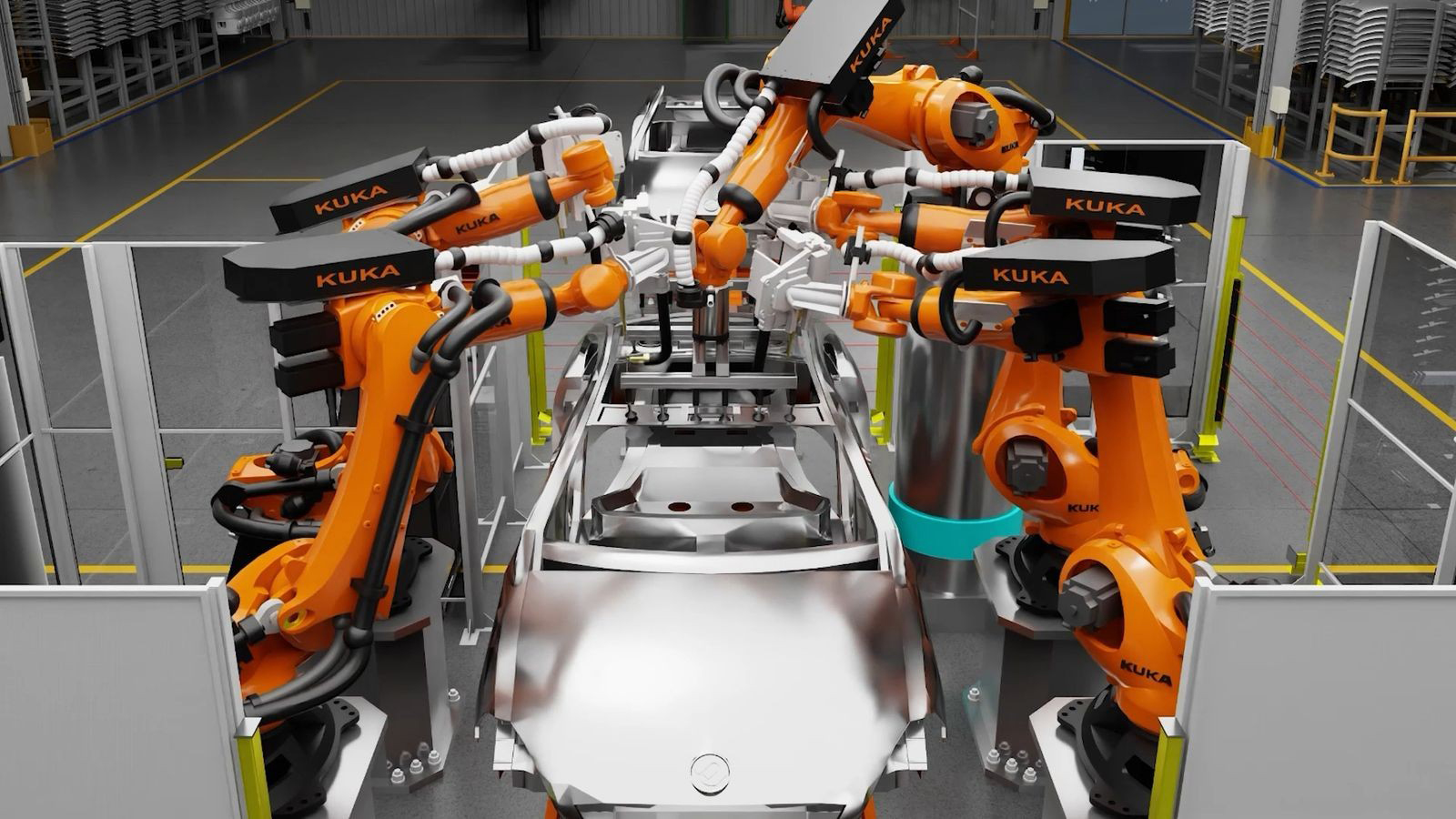

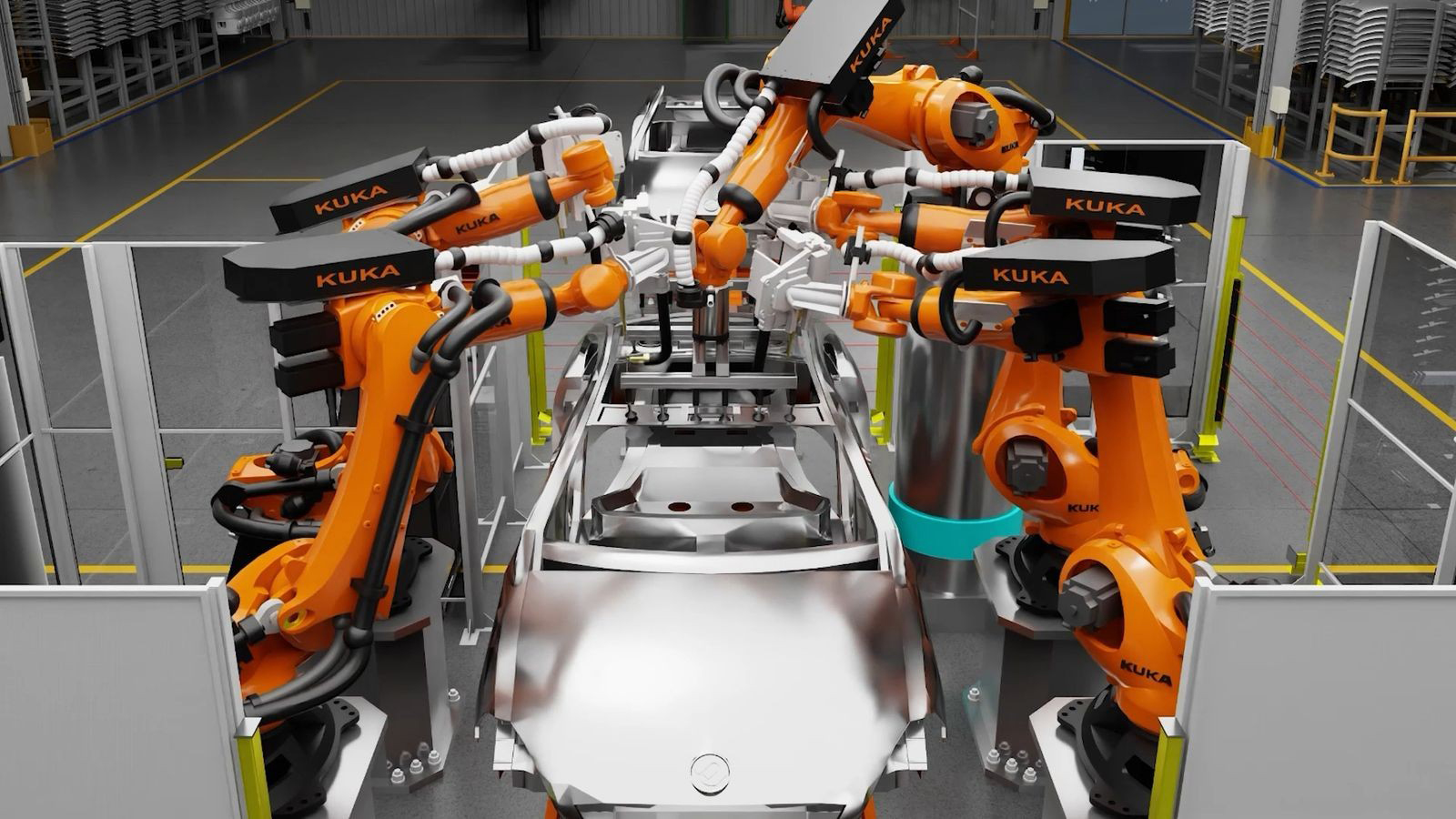

Visual Components announced its Omni Experience add-on virtual application with NVIDIA at the NVIDIA GTC global conference in Washington, D.C. Scheduled for release in early 2026, the integration enhances the Visual Components simulation platform with a new viewport built on NVIDIA Omniverse’s application programming interface (API).

|

|

| Control-Expert Days 2026 Offers New Insights into Global QA Market |

Control-Expert Days 2026 bridges the gap as Control trade fair shifts to a biennial schedule. This two-day event (expert presentations + exhibition) offers QA and metrology professionals networking opportunities and insights into the latest measuring technology innovations.

|

|

| KISSsoft for Humanoid Robots |

KISSsoft Gear Design Software from Gleason Corporation supports the design of compact, high-performance gear systems for humanoid robots, including high-ratio planetary arrangements and high torque-density gears. Engineers can optimize operating backlash, reduce noise through advanced tooth forms, and design plastic, sintered, and steel gears for efficient, precise robotic motion.

|

|

|

| EMAG Automation – Modular Robot Cell |

Discover EMAG’s MRC Modular Robot Cell – a flexible automation solution engineered for fast commissioning, standardized workpiece handling and seamless integration into machining production. Its modular design adapts to evolving tasks, reducing engineering effort and boosting efficiency, making automation accessible and scalable for modern manufacturing environments.

|

|

|

| Precision Starts with Accurate Feedback |

Cone Drive and Timken encoders deliver reliable, real-time feedback to support precise motion control. Designed for demanding industrial and automation environments, these sensing solutions help optimize performance and system confidence.

|

|

|

|

| The Game Changers: SH Series Vertical Hobbing Machines |

The SH Series from MTB offer the worldclass speed, accuracy and productivity you need for every job – at a price you can afford. Models available for parts as large as 425 mm diameter & custom packages that include ringloaders, chamfer cutting and provisions for extra-long shafts to 650 mm and hard skiving.

|

|

|

| Diamond dressing wheels manufactured in the USA |

Discover how diamond dressing tools are made in the USA. This video takes you inside KAPP TECHNOLOGIES in Boulder, Colorado. See how in-house production enhances flexibility, responsiveness, and delivery times by combining local manufacturing expertise with global engineering know-how.

|

|

|

| Precision Automation for Large Parts Handling |

New Gleason Automation for load/unload of larger parts speeds throughput, optimizes the process flow – and lifts the burden off the machine operator. The AR Series uses advanced vision guidance to ID the part and ensure proper orientation before loading it into the machine, even if it arrives without precise location directly from dunnage. Easily integrated with pre-and post-processes such as part washing, deburring, inspection and marking.

|

|

|

|