[please visit our sponsor]

Gear Factory of the Future

What does the future hold for the global gear industry? We’re asking these questions regularly in the pages of Gear Technology. Electric drivetrains, advanced optical metrology, an increase in automation and robotic capabilities, 3D printing, and the Industrial Internet of Things (IIoT) will continue to change the look and feel of the shop floor.

Additive Manufacturing—an Update

Writing about additive manufacturing (AM) and the 3-D printing of gears is somewhat akin to publishing an updated dictionary. A new edition dictionary is literally already out of date before it hits Amazon’s or your local bookseller’s shelves. New words are coined and definitions are updated constantly. So it is with AM—the technology is evolving so quickly that technical papers and other sources of AM information require constant revision.

Selecting Correct Size of Hob/Gashing Cutter

How does one select the correct size of hob/gashing cutter like hob OD, length and number of flutes for teeth cutting process based on tip circle diameter and face width of job?Expert response provided by Jin Zhou, gear tools engineer Nachi America.

Heat Treating 3D Printed Materials with Vacuum Technology

To improve 3D printed material and obtain precise mechanical properties, ECM Turquoise vacuum furnace systems easily perform stress relieving to remove residual constraints & disperse tension accumulated during manufacturing. ECM vacuum furnaces are also ideal for: annealing, solution treatment, ageing, brazing, sintering & more. 262-605-4810 www.ecm-usa.com

Read More

If we’re all in, we all win.

ARE YOU IN to reconnect with the global manufacturing community? Reserve your spot at this flagship event, showcasing all power transmission technologies: gear, electric, fluid power. Held live and in person this September, we expect fewer restrictions on travel and meetings. Let’s safely gather to facilitate new ideas and connections.

Read More

Pittler SkiveLine Increases Quality While Reducing Costs

The future of automation lies above all in the intelligent combination of the respective strengths of man and machine. In order to achieve better results, conventional procedures and processes are being rethought from the ground up. In industrial production, this is primarily a matter of improved ergonomics with a simultaneous reduction in manual processes.

Read More

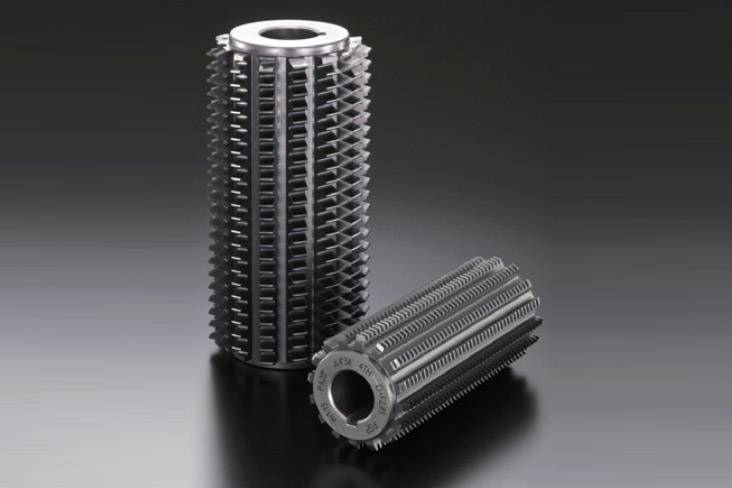

Your Source for High Performance Carbide Hobs

Gleason’s expanded line of solid carbide hobs brings improved performance to high-speed machining for both dry and wet cutting applications. These include everything from standard and special profiles for carbide hobs to standard and special carbide cutters for worm gears; Modules from 0.3 mm to 8 mm (DP 85 to DP 2.95); single and multiple-start hobs; with AlCroNite®Pro, AlCroNite®GearPro and AlNite® coatings.

Read More

Automate your grinding burn detection with RoboScan

RoboScan S Vertical is designed for the quality control needs of small to medium sized circular symmetrical parts like gears and passenger car shafts. RoboScan S Vertical provides fast and flexible measurements with high repeatability.

Read More

A New Dimension in Productivity

With Star SU Scudding® and skiving tools, quality meets speed with productivity 5 times faster than conventional gear cutting processes. Achieving surface finish and quality level far superior to traditional gear cutting technology, skiving allows the machining of internal or external gears/splines without the need of an undercut or groove.

Read More

Webinar: Improvement of Gear Life and Performance

Keeping gears in motion requires that friction compounded by high loading does not cause premature wear. Learn how Nitrex controlled nitriding is an effective way to improve the tribological properties of gears for unmatched reliability, performance, and longevity.

Register Today

PDS Offers Industry-Leading 24-Month Spindle Warranty

Protect capital equipment and help prevent unexpected challenges with Spindle Health Monitoring and PDS’s industry-leading PrecisionCareSM 24-month spindle warranty.

Installed into spindles or retro-fitted, the Spindle Health Monitoring System offers continuous spindle life monitoring using real-time vibration and temperature.

Read More

DELO and Infotech Collaborate on 3D Printing System

DELO, one of the world’s leading manufacturers of industrial adhesives for automotive, consumer and industrial electronics applications, has collaborated with Infotech, a Swiss-based company that recently introduced a unique and fully-automated system designed specifically for printing liquid materials and multi-material structures, to help with the production of components with different physical property ranges.

Read More

Come Join AGMA for Online Steels for Gear Application

Join us June 15-16th from 9am-1pm each day for AGMA’s online Steels for Gear Application. This course will count toward AGMA’s Advanced Gear Engineering Certificate! In this course, you will gain a basic understanding of steel and its properties as well as understand different steel and heat treatment options as well as performance. We hope to see you online!

Register Today

MHI Receives JSME Award for LAMDA AM

Mitsubishi Heavy Industries Machine Tool (MAT) has recently been awarded by JSME (The Japan Society of Mechanical Engineers) for achievements in additive manufacturing. The JSME Medal for New Technology was awarded to MAT on March 5th, 2021.

Read More

LK Metrology Enhances ALTERA C Accuracy and Speed

CMM manufacturer LK Metrology has designed a new, more efficient air bearing and carrier which are now being fitted as standard to its ALTERAC range of ceramic-bridge, multi-sensor CMMs. By significantly augmenting the pre-load on the structure, stiffness has been uprated without making the guideway thicker, leading to more precise motion control.

Read More