Tooth Root Load Capacity of Additive Manufactured Gears

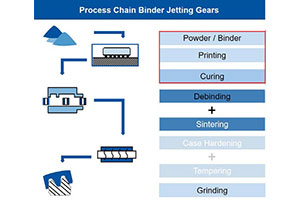

Due to near-net shape production, additive-manufactured (AM) gears have a high potential to decrease costs and increase resource efficiency. The decreasing product life cycles as well as the increasing individualization of components demand high flexibility in manufacturing processes. The production of powder metal (PM) gears by die pressing is only economical for large batch sizes or in series production due to the plant technology. An advantage of PM produced gears is the component density that can be adjusted through the sintering process compared to conventional machining. The porosity is accompanied by a reduction in weight and possible optimization of the noise vibration harshness (NVH) behavior of the gears. Due to the expected future shift of the automotive industry from combustion engines to electrified powertrains, the optimization of the noise behavior of transmission components is becoming increasingly important.

New Powder Metallurgy Industry Roadmap Released

The Metal Powder Industries Federation (MPIF) has announced the release of the 2023 PM Industry Roadmap. Key technology developments and example applications are identified for each of the four main categories of PM processes: press & sinter; metal injection molding (MIM); metal additive manufacturing (AM); and isostatic pressing. This update also reviews the achievements made by the PM industry from 2017–2022 and features interactive links to award-winning PM components.

Sinto America: Total Peening Solution Provider

Offering a full range of shot peening systems for gear manufacturing, cut-wire shot of various sizes, shapes and hardness levels and seven surface enhancement service centers throughout North America, Sinto America is your turn-key solution provider for the gear industry.

Post Additive Mfg. Heat Treating Vacuum Furnaces

ECM VACUUM FURNACES provide systems from single to multiple continuous batch production with robotic automation. No matter the process you are using for post additive heat treating, stress relieving, debinding, sintering and heat treating - ECM has your solution. ECM equipment meets all medical, automotive and aeronautics production requirements.

Read More

Surface® strong for over 100 years.

Surface® Combustion is built to keep you grinding. We pride ourselves as the leading heat treating furnace supplier, made with rugged construction and maximum quality. Built tough in the U.S., you can trust us to be your gears innovation solutions partner for long-term success.

Read More

oelheld’s DiaGrind: Increased Productivity & Cost Efficiency

Conquer your gear manufacturing challenges with oelheld’s DiaGrind series. Increase grinding wheel and cutting tool life, reduce grinding burn and burrs, gain excellent air release properties, and achieve machine cleanliness – all with DiaGrind. Successfully used on gear hobbing, grinding and shaping applications.

Read More

The Reliable Bevel Gear Supplier from Taiwan

With more than 30 years’ experience to supply bevel gears from Taiwan to the world, we are one of the leading bevel gear manufacturer in Asia.

We have qualified by IATF 16949, if you are looking for Automotive, Gear Reducer, and Machine center Bevel Gears, please feel free to contact us (service@yagergear.com).

Read More

3-chamber vacuum furnace w/oil quench doubles throughput

Demanding heat treat processes require high metallurgical quality and repeatability, attributes that are best achieved in vacuum. Oil quenching permits fast, uniform quenching of dense loads, improving productivity. CaseMaster Evolution® T-Type from SECO/VACUUM does both, and with a 3rd chamber for loading/preheating, it can double LPC throughput.

Learn More

Low Pressure Carburizing of Gears

Solar Atmospheres provides low pressure carburizing (LPC) that significantly increases the surface hardness/strength of steel parts for improved friction and wear. Performing LPC in a vacuum furnace eliminates oxygen and prevents IGO (intergranular oxidation) that is inherent in atmospheric carburizing, resulting in clean parts with less distortion reducing post process finishing operations, and costs.

Read More

Zero Carbon Target?

Induction is an eco-friendly heating method, as it does not generate carbon during the heating process. The electrification of the automobile and the manufacturing goal of a zero-carbon target process makes induction the perfect solution for heat treating, tempering, brazing, forging, and shrink fitting.

Read More

FVA-Workbench 8.0 Released

The latest version offers a wide range of powerful new features, from a new gear design module, to the influence of the wheel body during a complete rollover, to new display options for 3D images and animation of the gearbox kinematics in reports.

Read More

Robert Turk Named President of Precision Drive Systems

Precision Drive Systems (PDS), a global solution provider of precision motor spindles, expert engineering and support, and repair services headquartered in Charlotte, N.C., has announced today that Robert Turk has been promoted to the role of the company’s President.

Read More