Hobbing and Chamfer Cutting

It wasn’t long ago that cylindrical gear chamfering and deburring was almost an afterthought. Now the process ranks as high in importance as hobbing, shaping and grinding. Seemingly every gear manufacturer, particularly those developing transmission gears for e-drive applications, recognizes that anything less than a flawless tooth flank can result in premature transmission failure, less-than-optimal efficiency, and unacceptable noise. Thus, generating a chamfer to precise customer specifications is critical to minimize the potential for sharp, brittle edges after heat treat; avoid edge load situations in the gearbox; and eliminate excessive stock and hardened burrs in the tooth flank prior to the hard finishing operations (conditions which can greatly diminish tool life).

Fully equipped. For every job.

From automotive manufacturers to wind turbine producers, Liebherr gear hobbing machines are optimally customized to the requirements of universal usability. The high-performance machines are productive and machine in the highest quality. They can be used to manufacture workpieces from 60 millimeters up to oversized gears with a diameter of 16 meters.

Read More

A New Dimension in Productivity

With Star SU Scudding® and skiving tools, quality meets speed with productivity 5 times faster than conventional gear cutting processes. Achieving surface finish and quality level far superior to traditional gear cutting technology, skiving allows the machining of internal or external gears/splines without the need of an undercut or groove.

Read More

Auction of High-Volume Production Grinding & CNC Machinery

Online Auction, Closes March 30. Assets No Longer Needed for the Continuing Operations of Line Craft, a High-Volume Production Grinding and CNC Machining Supplier To The Powdered Metal & Stamping Industries For The Automotive Sector. Featuring: CNC Vertical Milling Machines • CNC Vertical Machining Centers • CNC Turning • Double Disc Grinding • Single Side Grinding • Fine Grinding • Centerless Grinding & More! Sale Conducted by Link Auctions

Read More

Seminar: Methods and Best Practices for Gear Process Engineering

May 9 to 11, 2023 - Don’t miss this three-day seminar featuring 8 Industry

Experts presenting comprehensive training for new gear process engineers.

The course features a full day on heat treat distortion. The seminar is sponsored

by Arvin Global Solutions and will be held at the Northern Illinois University

Facility in Naperville, Illinois.

Click here for More Information.

Take your gear grinding to a whole new level

Leave it to MTB to develop a Recontrol/Retrofit Package that takes your older Profile and Worm Grinding Machines to the performance levels of a new machine – all with less lead time and for a fraction of the cost. Available for all popular makes and models, both FANUC and Siemens CNC.

Learn More

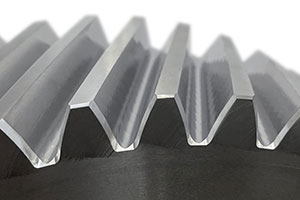

High Performance Carbide Hobs

Gleason’s wide range of solid carbide hobs and milling cutters brings improved performance to high-speed machining and dry cutting applications, including everything from standard carbide hobs to special cutters for worm gears or non-involute gears.

Learn More

Rugged Precision from High-Reduction Cycloidal Reducers

Webinar 3/31. Learn how cycloidal reducers can be the ideal choice for a wide variety of precision motion control applications, including robotics, medical/dental, aerospace/defense, machine tools and many more.

Read More

Croix Gear Expands Bevel Gear Capabilities

Croix Gear, a national leader in cutting bevel gears, has expanded production capabilities for spiral, straight, hypoid, and Zerol bevel gears. The completed software upgrades on three Gleason Phoenix 280c bevel gear cutting machines have expanded the cutting-edge precision and capacity for manufacturing spiral, straight, hypoid and Zerol bevel gears.

Read More

Spindles Repaired and Balanced for Higher Performance

PDS provides better-than-new spindle repairs for precision machining applications. Two-step balancing minimizes vibration well within specs, properly dressed grinding wheel, optimal finish with eliminated chatter marks and precision profile, waviness, size, taper, and roundness tolerances met. Standard delivery time is 3-5 days, with emergency service available. Call 704-922-1206.

Visit Us

Nidec + WENZEL Open House: Metrology and Motion

Join us on April 12th or 13th, 2023 and experience the latest gear making technology and metrology solutions! Experts from both companies look forward to meeting with you. Come enjoy lunch and refreshments while networking with all industries.

Please register before April 5th, 2023.

Register Now

Krebs & Reidel Offer Premium Grinding Wheels with High Process Reliability

Serial production of large gears requires a high level of quality, excellence, and continuity in production. Emphasis is placed on maximum synergy between the grinding machine, the grinding process, and the grinding wheel.

Read More

NUM Offers Tool Grinding Software to Denmark Tooling Company

TN Vaerktoejsslibning, Denmark’s second-largest precision tooling company, is deploying Numroto, the programming system for tool grinding from NUM across its entire production floor.

Read More