Cutting Tool Selection Criteria for Cylindrical Gear Manufacturing

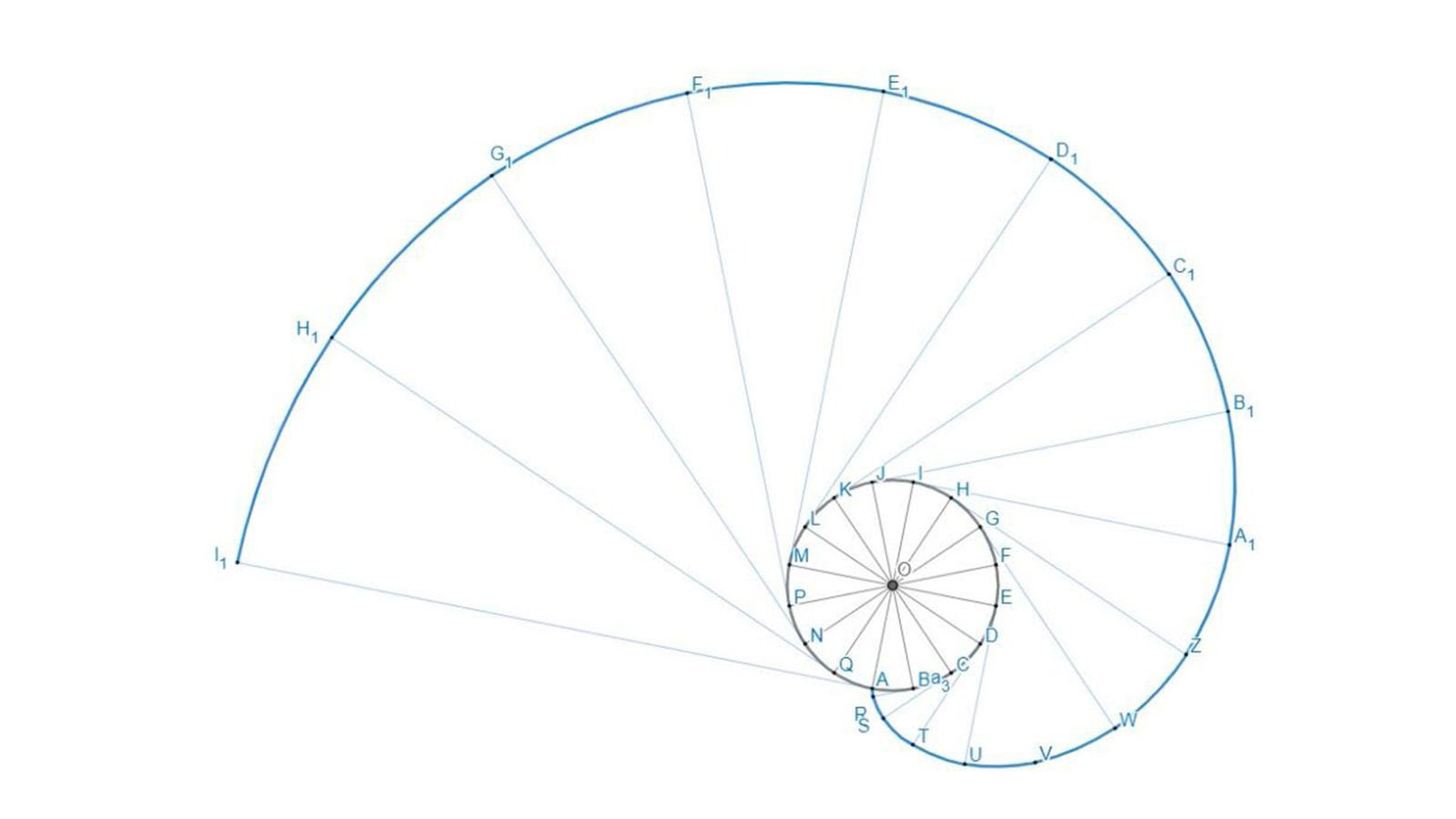

This paper is divided into two parts. The first part is a general digression on the pressure angle on cylindrical gears. The pressure angle is a variable that plays an important role in defining the geometry of gears and hobs, yet it is not widely discussed. This introduction serves as a prerequisite for the second part of the paper. The second part will show an application case of choosing the most suitable hob to cut a given gear. In this selection process, particular attention will be paid to the pressure angle of the hob for cutting with modified rolling, i.e., with a reduced pressure angle compared to that of the gear.

Precision and Innovation in Gear Cutting

Gear cutting has witnessed remarkable advancements over the years, with modern technologies transforming traditional methods into streamlined, highly efficient processes. NIDEC’s tools and methodologies increase productivity and quality in manufacturing. This article delves into the technological innovations, market relevance, and advantages of their gear-cutting solutions.

High Production Carbide Hobs

Star SU is a leading supplier of solid carbide hobs for gear tooth production. Our in-house carbide grades are available for cutting either green or hard materials and can be stripped and recoated. Application driven designs available in shell or shank configurations with multiple threads for maximum efficiencies.

Read More

Moving Knowledge Forward with Normalizing Furnace Solutions

Work with Surface Combustion to discover the best normalizing furnace solution for your processing needs. Featuring cast belt, roller hearth, and mesh belt configurations, our furnaces deliver normalizing and isothermal annealing solutions for metal processing. Contact Surface for all your heat treatment needs. Make Surface knowledge a part of your future.

Read More

Hardening/Tempering with ECM’s APEX Vacuum Furnace System

Reduce heat treat operating costs and improve overall process efficiency with ECM vacuum furnace technology. Achieve high hardness and improve wear resistance while minimizing distortion/oxidation when hardening/tempering for cutting tool heat treatments. Learn more about our new modular APEX Vacuum Furnace System integrated with tempering & robotics!

Read More

SEIWA G-TEC – High precision gear processing machines

Proudly representing Seiwa G-Tec’s portfolio of Horizontal and Vertical Gear Hobbing technology within North America. Founded in 1920, Seiwa G-Tec has over 90 years’ experience in machine tool production for gear cutting technology. Certified ISO 9001 since 2008, Seiwa always provides more value than cost.

- HOBBING

- SKIVING

- GRINDING

- HONING |(HELICAL/SPUR)

Read More

RoboDK Celebrates 10th Anniversary

RoboDK, founded in January 2015, is proudly celebrating its 10th anniversary. Since then, the company has grown from an academic spin-off into a global leader in robotic simulation and programming software. RoboDK now supports over 1,000 robots from 90 manufacturers and remains committed to making robotics accessible, affordable, and efficient for industries and educational institutions worldwide.

Read More

Join us for Basic Training for Gear Manufacturing

AGMA is hosting our Basic Training for Gear Manufacturing on April 7-11, 2025 in Chicago, IL at the AGMA National Training Center! For more information such as dates and times and registration deadline, click on the link below.

Register Now