KISSsoft for Gear Manufacturing

KISSsoft is a well-known software system that addresses gear manufacturing as a holistic process. With over 4,000 licenses sold worldwide, its functionality is dedicated to gear manufacturing and gear inspection and makes it easier for engineers—in the areas of calculation, manufacturing, and quality assurance—to collaborate and exchange data.

Experience the Power of Nano Inspection

Imagine evaluating waviness on a sub-micron level. Gear inspection solutions can enhance productivity with a single compact platform for the inspection of gears – even fine pitch gears smaller than 0.2 modules! Discover technology like Gleason’s GMS nano series Sept. 12-17 at IMTS 2022 in Chicago.

Read More

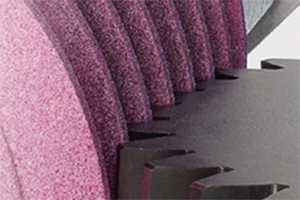

Transmission Noise Challenges? Go nano.

Gleason’s new 300GMS nano Gear Metrology System is built for today’s unprecedented transmission noise challenges and tooth form quality requirements. 300GMS nano delivers sub-micron analysis of tooth surface roughness after polish grinding; applies Advanced Waviness Analysis tools to detect and mitigate critical noise behavior caused by hard-to-find tooth form irregularities.

More Information

The key to greater transparency: LHWebPlatform

Gear cutting technology manufacturer Liebherr offers a unique platform of interfaces, data profiles and web apps for customized digitization solutions. It monitors in detail what, when, where, how and in what time something was manufactured. Evaluations and reports present essential indicators. It creates transparency for productions – and transparency creates productivity.

Read More

US Grinding Days

May 4-5. St. Paul, MN. Sponsored by 3M and Liebherr, this two-day program is designed to provide attendees with industry insights into the latest gear grinding methods, technology and related topics. An evening welcome reception and a social event will provide guests with an opportunity to network with gear grinding industry leaders and peers. Topics include gear grinding innovations, grinding methods for e-drive and robotics, measurement and inspection, finishing and polishing techniques, and robotic grinding.

Register Today

Seco Milling Cutters Reduce Tooling Inventory Costs

Manufacturers who look for versatility and precision in machining can pair up Seco Turbo 16 square shoulder milling cutters and Helical Turbo 16 milling cutters to reduce tooling inventories and costs.

Read More

Sandvik Coromant Examines Shift to Electric Vehicles

According to a report by the International Transport Forum, global transport activity is expected to double by 2050 compared to 2015 levels. With climate change a global concern, it’s important that we produce more efficient vehicles that run on greener fuels.

Read More