Aspects of Gear Noise, Quality, and Manufacturing Technologies for Electromobility

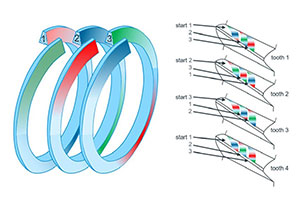

Start 1 of the grinding worm will devolve its characteristic on tooth 1, start 2 on tooth 2, start 3 on tooth 3, and so on. When grinding the gear is finished, each flank has a slightly different surface texture and therefore the ghost orders and side bands with low amplitudes are induced in the order spectrum. With this grinding technology called Quiet Surface Shifting (QSS), it is possible to produce gears of the highest quality and improved psychoacoustic values in loudness, tonality, fluctuation strength, and sharpness resulting in less noise annoyance of transmissions.

Krebs & Reidel Offer Premium Grinding Wheels with High Process Reliability

Serial production of large gears requires a high level of quality, excellence, and continuity in production. Emphasis is placed on maximum synergy between the grinding machine, the grinding process, and the grinding wheel. Krebs & Riedel is a manufacturer of grinding wheels for gear grinding in the automotive and EV sector and is also expanding into other sectors where large gears are manufactured with the new Blue Moon TZ premium product range.

Powerful Combination for Complex Gears

Accommodating up to four different power skiving tools on two spindles, plus up to six turning tools, EMAG’s VSC 400 PS combines power skiving and turning for producing internal and external gear teeth on a single, simple to operate machine.

STAR NXT HOB SHARPENING

The Star NXT sharpens both straight and spiral gash hob design up to 8” OD x 10” OAL, as well as disk, shank, and helical type shaper cutters, Scudding® and skiving cutters, and a wide range of round tools making it a versatile tool room machine.

LEARN MORE

Nidec Gear Manufacturing Machines + Nidec Cutting Tools

Legendary Reliability + industry leading cutting tools + fast turnaround tool sharpening and recoating = profits!

Get your hobs with quick delivery from the company who invented dry hobbing. New substrates and advanced coating provide predictable and reliable tool life.

Read More

Croix Gear has installed a new Gleason Phoenix II 600HC

Bevel Gear Cutting Machine to expand capacity and precision capabilities for spiral, straight, hypoid, and Zerol bevel gears.This addition will increase size capabilities to 24" OD for all bevel gears, increase capacity, reduce lead times, and improve part quality and repeatability.

Read More

The Game Changers: SH Series Vertical Hobbing Machines

The SH Series from MTB offer the worldclass speed, accuracy and productivity you need for every job – at a price you can finally afford. Models available for parts as large as 410 mm diameter. With custom packages that include automation, on-board chamfer/deburring and provisions for extra-long shafts to 650 mm; even hard skiving.

Start doing more, for a lot less

Stop grinding your gears and start doing more with less.

Better efficiency, happy customers, and a better bottom line are just three steps away. Download the 3 Ways Manufacturers Do More With Less whitepaper today to learn how the best gear manufacturers are staying competitive and simplifying their manufacturing.

DOWNLOAD >>

Small but powerful

25 millimeters – the size of a two-euro coin – is the diameter of the new CBN grinding discs developed by Liebherr specifically for machining critical component geometries with low tool overrun. They can be coated with specifically selected grain for longer service life and faster grinding processes.

Read More

Up Your Uptime. Down Goes Downtime.

Spindle vibration is a significant indicator of impending failure. Spindle bearing failure can cause chatter on workpieces and unmet tolerances. With VibeAid℠, Precision Drive Systems can help diagnose and report these spindle issues onsite, providing the opportunity to affordably correct them without the cost of downtime due to spindle failure.

Read More

Every Road To Success Starts With The Right Route

America is the place where legends are born. Just as the legendary Route 66 evokes the spirit of cross-country adventure, opportunity, and experience, SECO/WARWICK Group likewise embodies this same spirit in pursuit of heat treatment excellence. Born and raised in Pennsylvania, SECO/VACUUM offers the best technologies #made4America.

Check out our vacuum solutions and explore your American journey with us.

Read More

Marposs Offers Compact Optical Tool Setter for Small Applications

Marposs, a leader in measurement, test and inspection technologies, has expanded its VTS (visual tool setter) family with the new VTS SF-45 Compact, suited for non-contact, optical measurement of small, complex-shaped tools in constrained working spaces such as micro-machining, semi-conductor or moldmaking applications.

Read More