Maximizing Wind Turbine Gearbox Performance with Advanced Engineering Simulation

ZF Wind Power has implemented Siemens Simcenter Flomaster software, a system-level thermo-fluid simulation tool, to streamline their engineering design processes and improve the productivity of their teams. A business unit of ZF Friedrichshafen, ZF Wind Power is a leader in designing, manufacturing, supplying, and servicing wind turbine gearboxes. Prior to implementing the Simcenter software, ZF Wind Power relied on Excel spreadsheets to calculate the appropriate flow rates and pressures of the gearbox flow paths. According to Jo Loenders, product management engineer, ZF Wind Power, this was “a very complex and time-consuming process, as the distribution systems for the lubrication can involve hundreds or even thousands of small components that result in pressure losses.”

Closed Loop for Gears: Some Case Studies

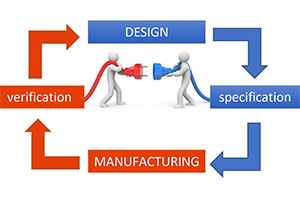

The closed-loop concept has become widespread in recent years, especially in relation to the Industry 4.0 concept. The term “closed loop” will be used herein to refer to the pairing of specifications and checking which all ISO standards, starting with ISO 1, the “mother” of all standards, use in relation to GPS (Geometrical Product Specifications).

The key to greater transparency: LHWebPlatform

Gear cutting technology manufacturer Liebherr offers a unique platform of interfaces, data profiles and web apps for customized digitization solutions. It monitors in detail what, when, where, how and in what time something was manufactured. Evaluations and reports present essential indicators. It creates transparency for productions – and transparency creates productivity.

Read More

Seminar: Methods and Best Practices for Gear Process Engineering

May 9 to 11, 2023 - Don’t miss this three-day seminar featuring 8 Industry

Experts presenting comprehensive training for new gear process engineers.

The course features a full day on heat treat distortion. The seminar is sponsored

by Arvin Global Solutions and will be held at the Northern Illinois University

Facility in Naperville, Illinois.

Click here for More Information.

Croix Gear Installs Gleason Phoenix II 600HC Bevel Gear Cutting Machine

Croix Gear & Machining, recognized as a leader in the custom manufacturing of loose gears, is excited to announce the installation of a Gleason Phoenix II 600HC Bevel Gear Cutting Machine.

Read More