Nidec Machine Tool Develops Polish (Grinding) Method to Process Internal Gears for Mass-Production

Nidec Machine Tool Corporation has developed a high-accuracy polishing (grinding) method to machine internal gears for mass production that are used for automobiles’ drive units and transmissions and robots’ joints. While there are already high-accuracy polish-machining methods for external gears for mass production, no such methods have been available for internal gears. After conducting research focused on this point, Nidec has achieved positive results in securing the level of accuracy and production that conventional grinding, honing, or skiving methods could not.

Four Tips to Optimize Quality and Reduce Cycle Time in Gear Tooth Profile Grinding

Gear tooth profile grinding, also known as form grinding, is a finishing method used in gear manufacturing. It involves the use of vitrified bonded grinding wheels to modify or correct the profile of gear teeth, often after heat treatment. The grinding wheel runs between two opposing teeth, grinding both surfaces at the same time.

MAR – a landmark in the world of grinding machines

- Natural granite machine beds

- Electro spindles

- Torque rotating grinding wheel turret

- Ball screws or linear motor technology

- Glass scales

- Multi-wheel OD/ID platforms available

- Siemens or Fagor CNC controls

- Universal Torque workhead with integrated angular position control

- MAR designed simplified HMI

- Compact machine design

Read More

Our High Torque Gears Fill a Key Design Gap.

For over six decades, we’ve helped top engineers tackle tough gearing problems. Application industries include: Robotics, Aerospace, Defense, Transportation and Medical.

Learn how our gearing systems can be leveraged in your sector. Contact our engineers today at 320-762-7133.

for more information.

Download Case Studies Here>

New Norton Quantum Prime Is Revolutionizing Grinding Wheel Performance

Witness a Grinding Revolution! Norton Quantum Prime Wheels feature new, proprietary nano-crystalline ceramic grain that delivers exceptionally high grinding efficiency and part quality, as well as significantly longer wheel life than traditional ceramic grains. Quantum Prime grain is providing unprecedented productivity gains across a broad array of applications including gear grinding.

Learn More

Master Gears and Gauges from Star SU

Star SU offers a wide range of precision gauges for measurement, calibration, setting, and correction purposes including; master gears, setting masters, and rolling gears. Learn more about the entire offering:

Read More

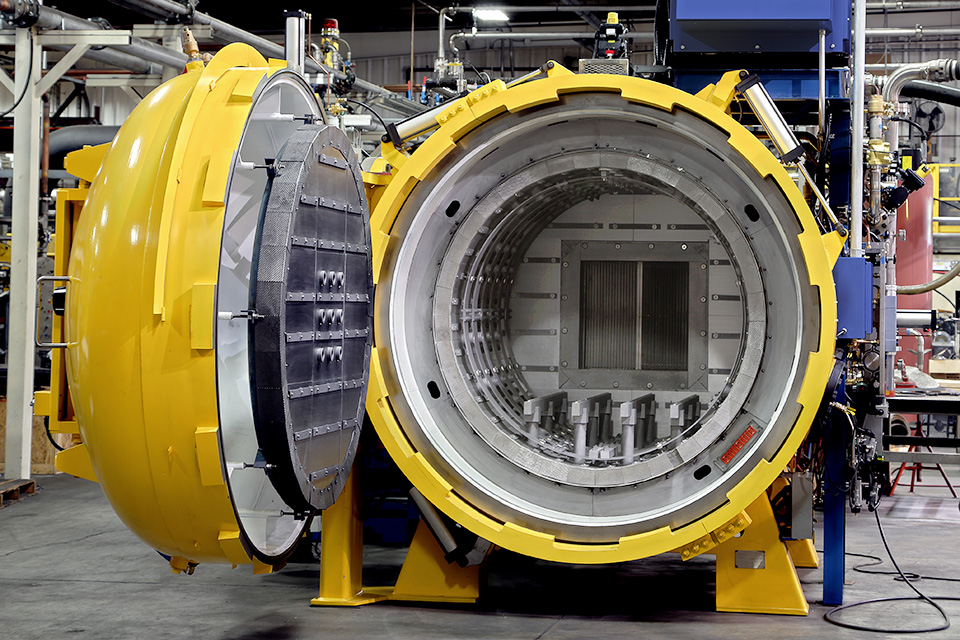

High Pressure Quench Vacuum Carburizing Furnaces

Get fast, forceful gas cooling with Solar Manufacturing’s IQ series of vacuum carburizing furnaces. It’s high performance internal quench system with direct-exit, sliding radiation baffles is the least restricted gas flow path on the market for superior hardening at quench pressures up to 20 bar.

Contact us to learn more about our vacuum furnace ingenuity.

P: 267.384.5040

Read More

Prepare for growth! NIDEC has gear machines in stock.

Get ready for the predicted growth for the gear industry in the second half of 2024. Upgrade your efficiency, production and capacity with NIDEC's quality, reliability and precision. NIDEC Machine Tool America has hobbers, shapers and gear grinders available for nearly instant delivery. Call Scott Knoy today at 248-756-5017.

Read More