[please visit our sponsor]

Delivering on the Promises of Digital Twins and Big Data

As a community, we gear engineers collaborate and share ideas to progress our collective capability. Technology progresses based on our efforts, and we have seen solid advances in the performance of our products as they become quieter, cheaper, more efficient, and more power dense. The pages of this magazine (past and present editions) are filled with examples where talented engineers have dug deeper into a subject using a more precise approach to a particular area concerning gear performance. The implied belief is always that greater precision (complexity) in the calculations brings greater accuracy (alignment with reality).

Cross-Correlation of Design Variables for Epicyclic Systems

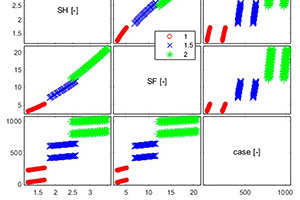

The automotive industry pays great attention to the concept of power density and friction losses concerning mechanical transmission systems. Moreover, installation benefits and weight reduction are achieving higher density power. Another important study is about mechanical efficiency: their reduction allows to minimize the heat exchange; the power dissipation problem—produced by friction—must be addressed. Therefore, the gear designer is obligated to incorporate additional cooling systems, or with higher capacity, to address this problem. This paper shows a methodology to extensively evaluate different designs of epicyclic gear systems.

Beat fear of the unknown.

Don’t let fear of tomorrow cripple you today. Here are the 5 methods helping manufacturers achieve greatness today and for the future. Read the 5 Changes Manufacturers are Making Today and for Tomorrow whitepaper now.

Give Me the Whitepaper

The key to greater transparency: LHWebPlatform

Gear cutting technology manufacturer Liebherr offers a unique platform of interfaces, data profiles and web apps for customized digitization solutions. It monitors in detail what, when, where, how and in what time something was manufactured. Evaluations and reports present essential indicators. It creates transparency for productions – and transparency creates productivity.

Read More

How Will You Innovate at IMTS?

Manufacturing innovators come to IMTS, The International Manufacturing Technology Show, to connect, find inspiration, and discover solutions. Join innovators like Matt Gawlik of 3D Graphite & Machining Inc. at McCormick Place in Chicago, September 9-14, 2024.

Read More