|

Get the freshest updates on gear technology

|

|

|

|

| E.T. Hone Home |

For more than 60 years, Forest City Gear has crafted a legacy of excellence in precision gear manufacturing, leveraging advanced techniques and cutting-edge technology to earn the business of customers as exclusive as NASA. At the heart of the company’s technology-focused philosophy lies a long-time relationship with Sunnen Products Company, a leading manufacturer of honing systems, tooling, and accessories. The relationship helped Forest City set itself apart as one of the world’s most precise gear makers, and now the company’s parts are found on everything from fishing reels to the Mars Rovers.

|

|

| Precision and Innovation in Gear Cutting |

In response to growing demands for high-precision gears, particularly in industries like automotive and aerospace, NIDEC has developed tools that support the latest gear manufacturing techniques. These techniques, such as gear grinding and honing, are used more frequently after heat treatment to achieve the desired accuracy and reduce gear noise and vibration. While grinding and honing typically involve additional post-heat treatment processes, these techniques ensure that the gears meet strict precision standards.

|

|

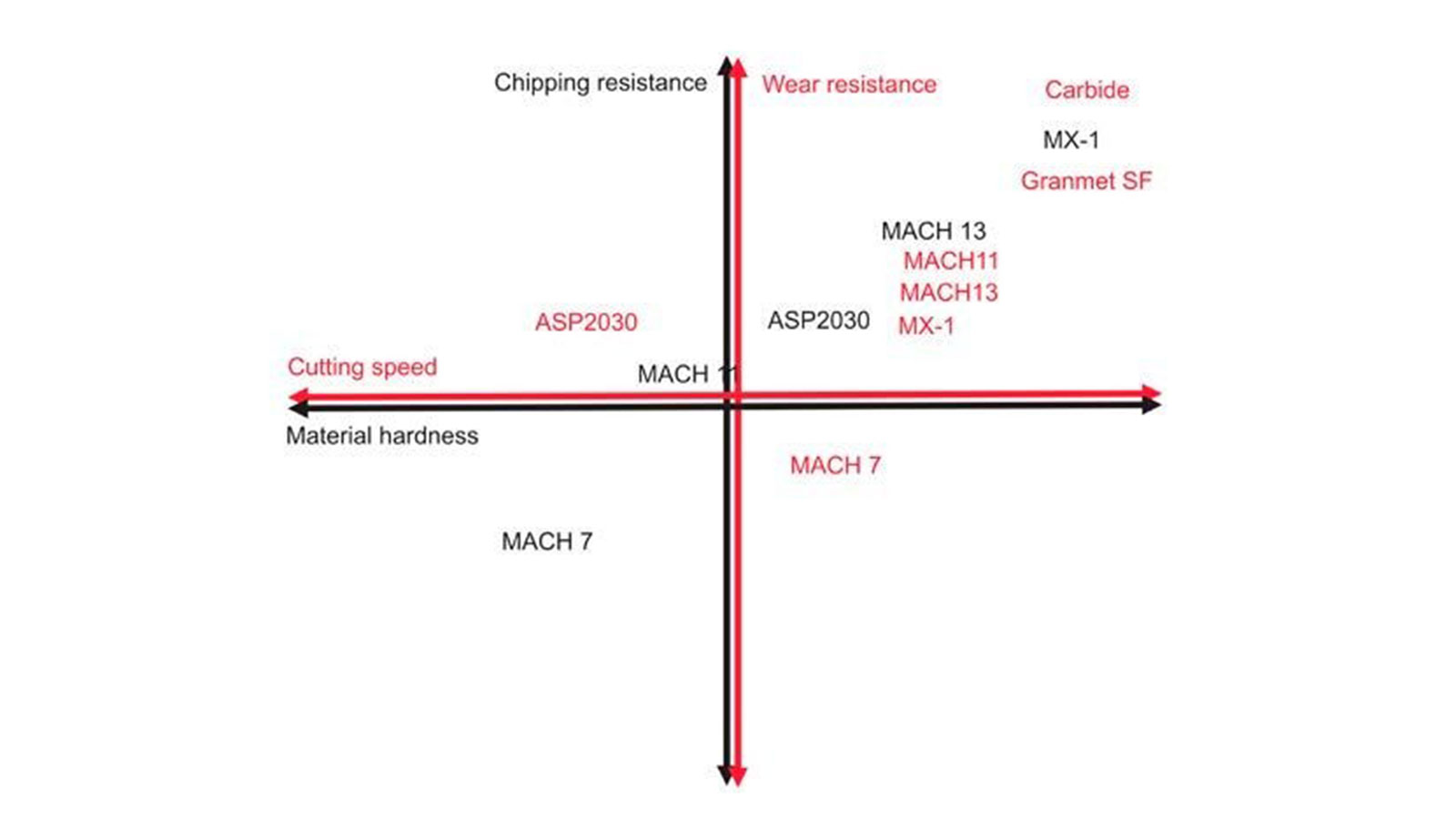

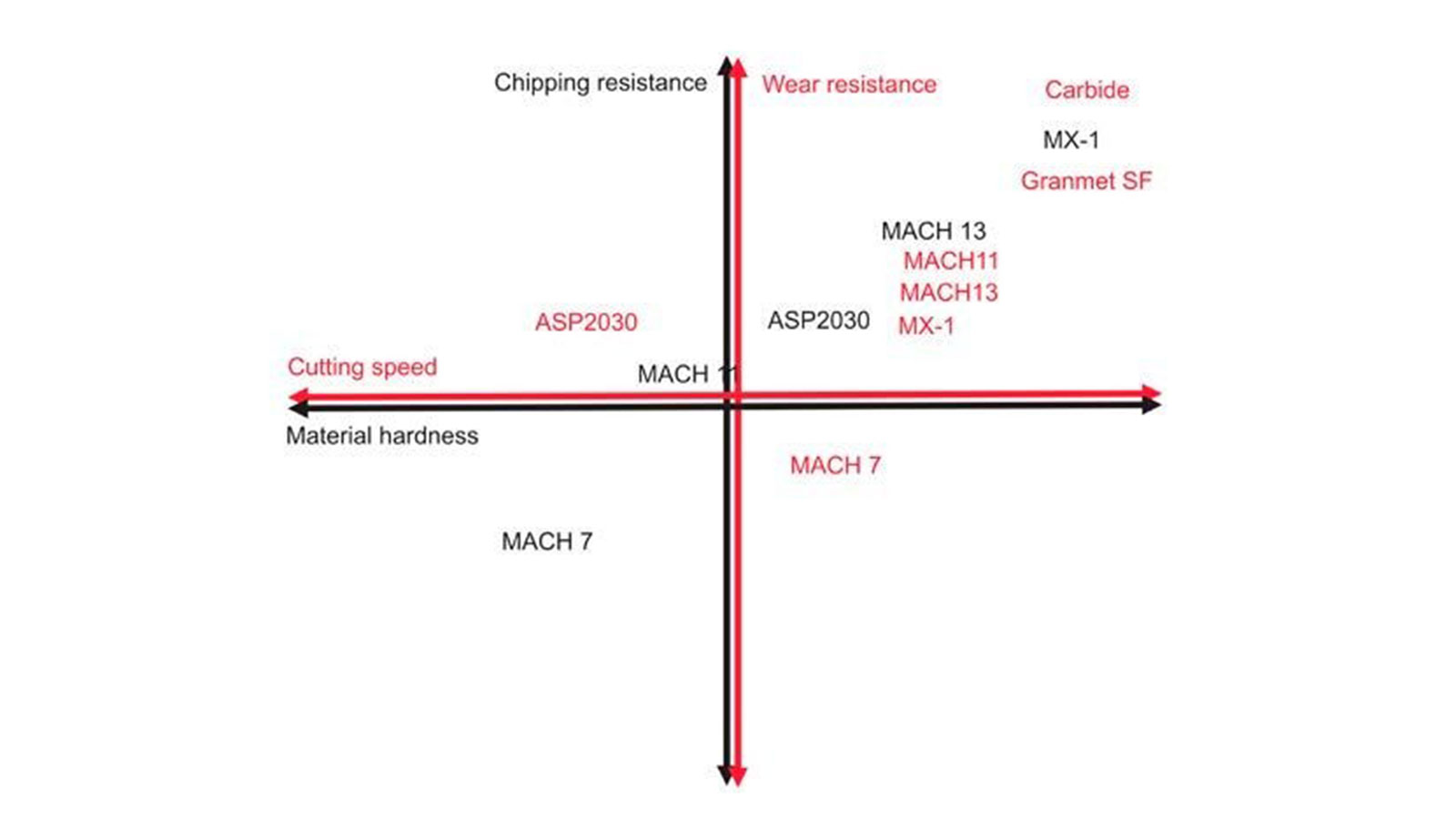

| High Production Carbide Hobs |

Star SU is a leading supplier of solid carbide hobs for gear tooth production. Our in-house carbide grades are available for cutting either green or hard materials and can be stripped and recoated. Application driven designs available in shell or shank configurations with multiple threads for maximum efficiencies.

|

|

|

| Vacuum Carburizing With Gas Quench And No Oil |

Low-Pressure Carburizing (LPC) is the future of case hardening, and many materials can be carburized and quenched without oil. The versatile Vector® high pressure gas quench vacuum furnace from SECO/VACUUM handles a wide range of heat treatment processes including LPC and Low-Pressure Nitriding (LPN).

|

|

|

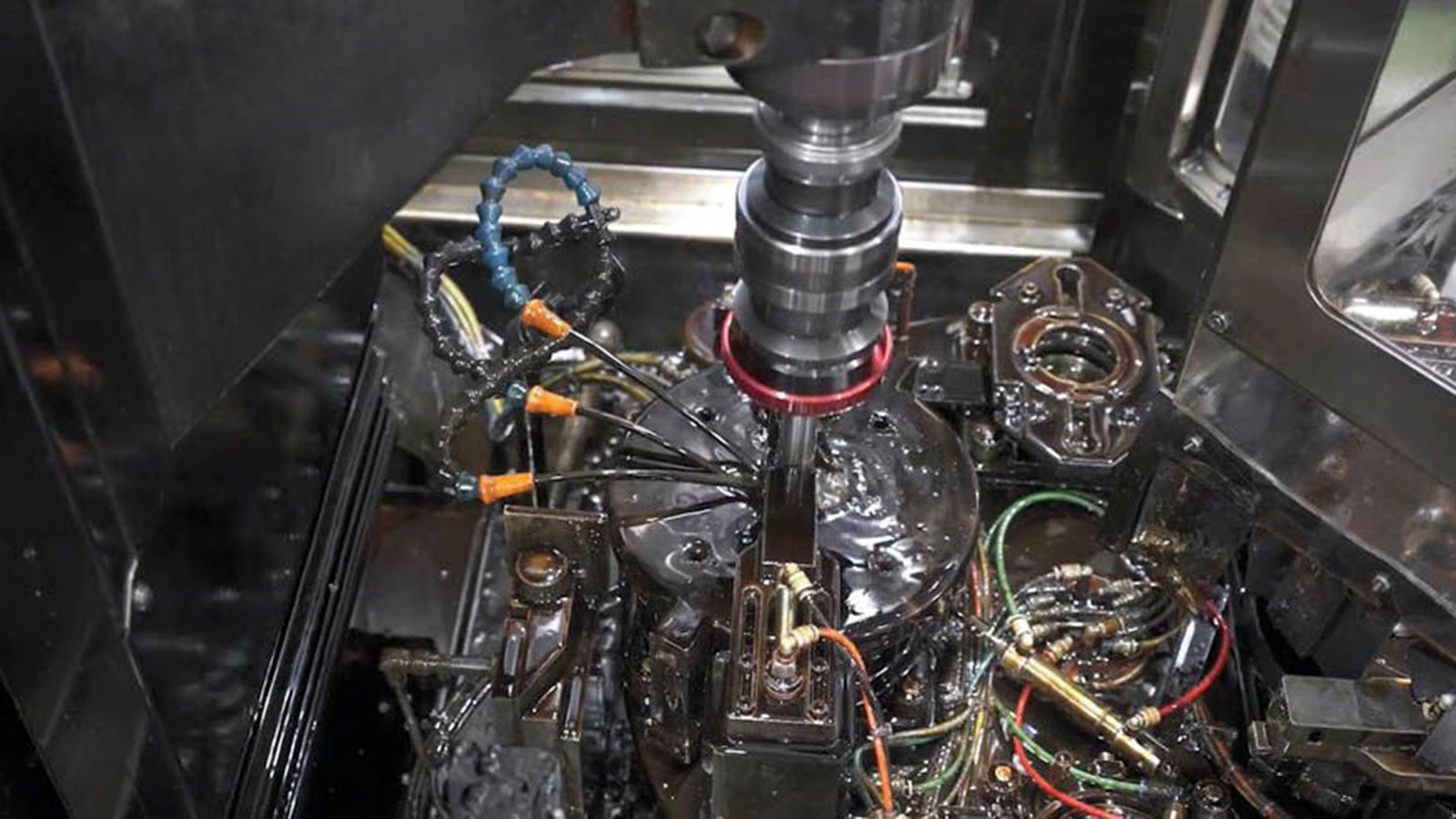

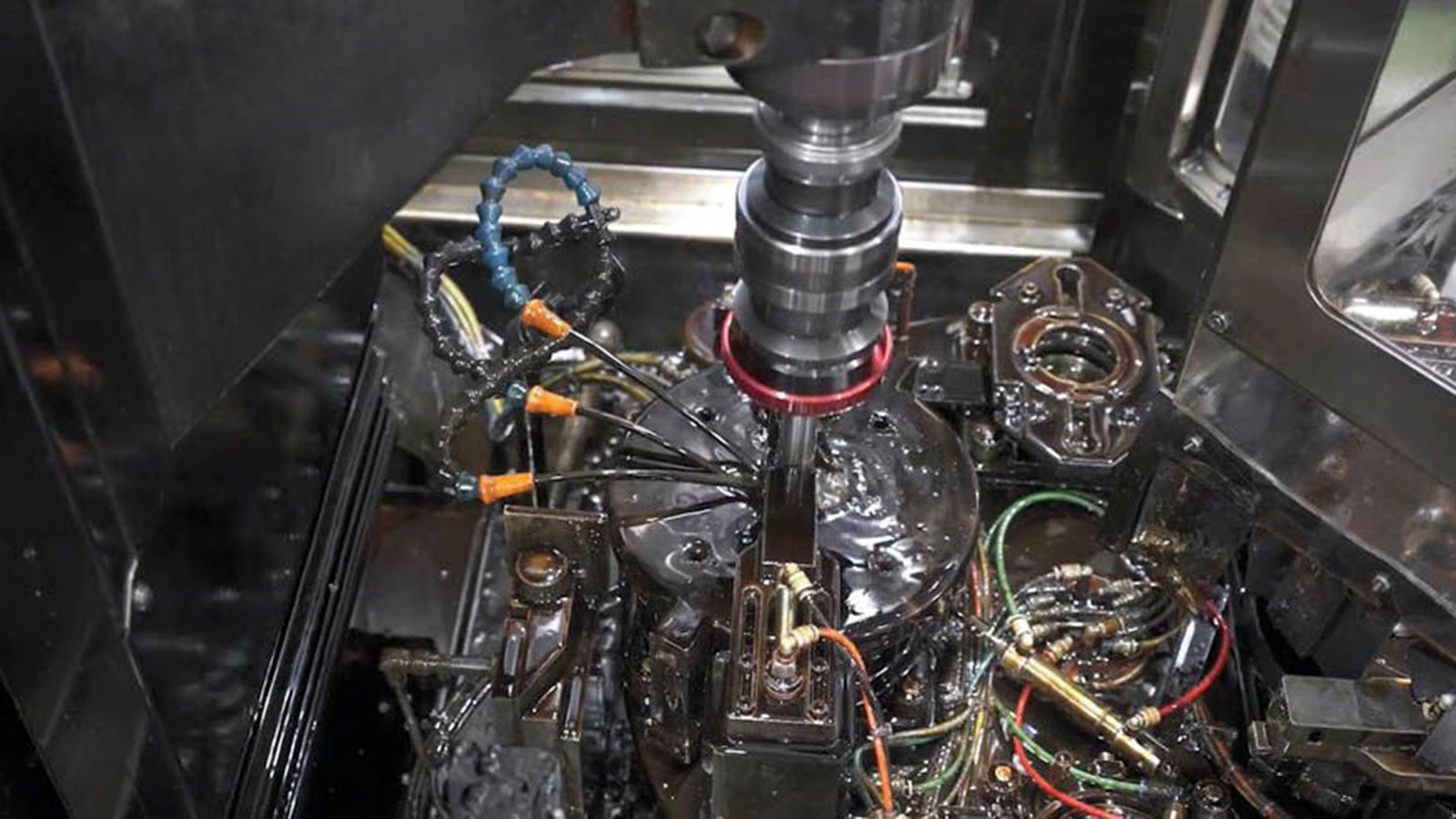

| Combi Honing for Faster Production of Quieter Gears |

With Combi Honing, finish two gears on one workpiece in a single setup, or use two honing rings on the same gear to achieve excellent surface finishes. Combi Honing is the perfect solution for e-drive stepped pinions and similar transmission gears with timing requirements. Two honing rings in one setup offer an exciting alternative to polish grinding, especially for parts which cannot be ground due to interferences. Gleason Gear Honing Machines are part of a complete hard finishing system including grinding and dressing tools, as well as application knowhow to ensure maximum quality within minimum cycle times.

|

|

|

|