[please visit our sponsor]

Simultaneous Grinding of ID, OD and Faces of Gears

Junker has introduced the JUMAT 6S 18-20S-18, the latest of Junker's JUMAT series of modular grinding machines, which is capable of grinding the ID, OD and faces of a gear simultaneously.

Junker has introduced the JUMAT 6S 18-20S-18, the latest of Junker's JUMAT series of modular grinding machines, which is capable of grinding the ID, OD and faces of a gear simultaneously.

Gear Grinding with Closed Loop: The Next Level

Gleason Genesis® GX Series Threaded Wheel Grinding Machines take high-volume, high-quality gear finishing to a new level, with features like single-tool setup, twist-controlled grinding and integrated automation. Our Closed Loop System networks a Gleason GMS inspection machine directly to the GX for fast, reliable, automatic data transfer and corrections.

Gear Expo 2017 — The Drive Technology Show

Join thousands of drive technology experts and power transmission professionals for three days of industry-related events.

Gear Expo is where gear buyers, end users, manufacturers, and engineers from power transmission industries come to discover innovative technologies, network, and build relationships.

Read More

Pentac®Mono RT Cutter System: Fewer Blanks, Greater Tool Life

Gleason's new Pentac®Mono RT is the first bevel gear cutter system featuring outside and inside slots using the same identical blades. Users now can reduce the number of different blade blanks by 50%, and double tool life by swapping the blades from the outside slots to the inside slots and vice versa, and then using the cutter with the same blades for a second run.

Read More

The precision measuring center for "seamless" workpiece measurements — replacing gauges.

Klingelnberg celebrated a premiere with the new P 16 G on the Control show in Germany: a measuring center for round components that was developed specifically for use on the shop floor. The P 16 G is designed around measurement tasks outside of gears and aims to replace gauges in production.

Read More

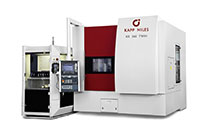

Minimize your idle time with the KX260 TWIN

Here's the ideal partner for medium and large batch production. The KX260 TWIN has the power for heavy duty truck gears while keeping idle time at a low of 3 sec. Automation-ready, speed for mass-production and on-board or remote inspection — the KX260 TWIN elevates continuous generating grinding to a new level.

Read More

PITTLER Power Skiving for highly efficient gear cutting

Power Skiving by pioneering PITTLER T&S allows for highest-quality internal and external gearings to be machined fast, flexible and at low tool costs. Based on its PV 5-axis turning center, PITTLER T&S offers Power Skiving for rotation-symmetrical components up to a diameter of 50″ either as complete or individual machining solution.

Read More

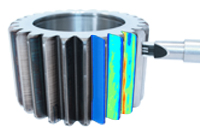

CASE STUDY DOWNLOAD: Nital Etch vs. Barkhausen Noise

Learn how customers increased their analysis accuracy and repeatability, and cut costs by reducing scrap and eliminating the need for chemical disposal. This non-destructive testing method for grinding burn detection and heat treat defect detection improved product quality and resulted in significant cost savings.

Read More