Prediction of Process Forces in Gear Honing

Gear honing is a highly productive process for the production of small and medium sized gears and is used mainly in the serial production of the automotive industry. The low robustness of the process is a particular challenge in gear honing. The consequences range from an inadequate gear quality to an early breakage of the honing tool. In order to describe the processmachine interaction, the machining forces must be known.

Origin Stories Continued

Stop by the blog to read the latest in our ongoing series of gear industry Origin Stories. Recent entries describe how James Richards, Bob Handschuh and Dave Hinz got their starts in gear manufacturing.

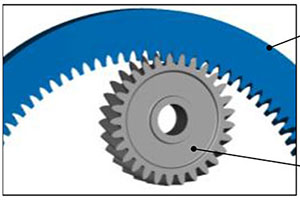

PRÄWEMA improves the surface quality of internal gearings

Just like the proven gear honing technology for external gearings, PRÄWEMA's new honing technology for internal gearings fulfills the highest standards for surface and profile quality of toothed parts so that ring gears can now be machined in hitherto unequaled productivity and manufacturing quality.

Read More

Gleason GX Series with Closed Loop: Finish First

Gleason Genesis® GX Series Threaded Wheel Grinding Machines

take high-volume, high-quality gear finishing to a new level, with features like single-tool setup, twist-controlled grinding and integrated automation. Gleason Closed Loop System networks a GMS® inspection machine directly to the GX for fast, reliable, automatic data corrections.

Read More

The Motion + Power Technology Expo

At MPT Expo, you'll see the entire power transmission supply chain - with mechanical, fluid power, electric, and hybrid solutions. Sign up for the MPT Conference, a two-track event focusing on business trends and emerging technologies. Additional technical education includes AGMA's Fall Technical Meeting and education sessions hosted by industry experts.

Read More