[please visit our sponsor]

You Have Questions. We Have Answers.

Gear Technology's "Ask the Expert" column has been one of our most popular features over the years. But our experts are getting bored and lonely! Give us some questions, and we'll help you get the answers you need, while educating the gear industry at large! We're looking for your technical questions on gear design, manufacturing, inspection and use. And just like when you were in school, there are no dumb questions!

Optimal Polymer Gear Design: Metal-to-Plastic Conversion

Nowadays, the progress in polymer materials and injection molding processing has enabled a drastic expansion of plastic gear applications. They are used not only for lightly loaded motion transmissions, but also in moderately loaded power drives in automotive, agriculture, medical, robotics, and many other industries.

WHEN MACHINE FAILURE IS NOT AN OPTION...

They call on Spiroid™. Our gears allow greater torque in less space with reduction flexibility and positive backlash control. Spiroid’s unmatched skew-axis, high torque gears enable world-class power density.

Get in touch with our engineers to see if Spiroid is the best fit for your application. 320-762-7133

Learn More

Gear Carburizing in Vacuum

Solar Atmospheres provides low pressure vacuum carburizing (LPVC) that significantly increases the surface hardness/strength of steel parts for improved friction and wear. Performing LPVC in a vacuum furnace eliminates oxygen and prevents IGO (intergranular oxidation) that is inherent in atmospheric carburizing, resulting in clean parts with less distortion reducing post process finishing operations, and costs.

Read More

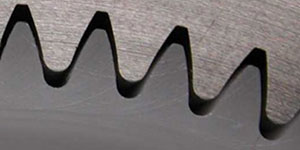

Gear cutting tool solutions from Star SU

Star SU carries a wide variety of new cutting tools and provides precision tool re-sharpening services. In addition, advanced coatings, including Oerlikon Balzer's ALTENSA and Alcrona Pro, are available and can increase cutting speeds, extend the life of your tools and lower your costs...

Read More