Recent Cutting Tools from Kennametal, Star SU, and Seco Offer Improved Tool Life and Precision

Cutting tools are basic to gear manufacturing. Whether it's a hob, broach, shaper cutter, or skiving tool, the object of cutting tools remains the same: material removal that is fast, accurate, and cost-effective. The field tends to evolve gradually in the machines, materials, and coatings that make cutting tools even more useful, but reliable cutting tools are essential to production-process efficiency, and recent solutions from Kennametal, Star SU, and Seco deliver improved wear resistance, removal rates, and precision.

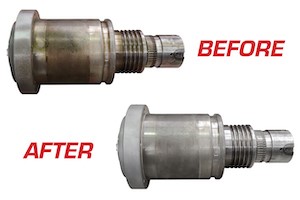

Spindles Repaired and Balanced for Higher Performance

PDS provides better-than-new spindle repairs for precision machining applications. Two-step balancing yields; minimized vibration well within specs, properly dressed grinding wheel, optimal finish with eliminated part chatter marks and precision profile, waviness, size, taper, and roundness tolerances met. Standard delivery time is 3-5 days, with emergency service available.

High Production Carbide Hobs

StarSU is a leading supplier of solid carbide hobs for gear tooth production. Our in-house carbide grades are available for cutting either green or hard materials and can be stripped and recoated. Application driven designs available in shell or shank configurations with multiple threads for maximum efficiencies.

Read More

Optimized design for best performance: Gear skiving tools

Due to its process-specific kinematics, skiving can be a complex and unforgiving process. Liebherr is consistently working on the development of its gear skiving tools. With the help of a simulation, Liebherr can identify potential tolerances in the process kinematics. The findings are then used to maximize tool life and increase cost-efficiency.

Read More

SECO/VACUUM has the Nitriding technology you need

SECO/VACUUM’s retort nitriding furnaces are available in more standard sizes and types than any other manufacturer. In addition to Nitriding, they are also used for Ferritic Nitrocarburizing (FNC) with post oxidation. SVT’s patented ZeroFlow® control technology with vacuum purge assures optimum results at low operating costs.

Click to learn more.

Horizontal Hobbing Machine Delivers Grind Quality Results

Japanese machine tool manufacturer HAMAI delivers game-changing performance, quality & value with the N-Series lineup Horizontal Hobbing machines offering super high-speed, high-precision hobbing, 7-Axis, 6,000 RPM, Shaft Lengths 350 mm, Wet/Dry, Optional Automation, Grind quality results. Only available at Machine Tool Builders Inc (MTB), schedule your virtual demo today!

Read More

Sandvik and KINTO Collaborate on Car Sharing Program

The first phase is now initiated of what will be a brand-new mobility hub of fuel cell and plug-in hybrid cars that will be available to everyone in Sandviken, Sweden. The initiative is a joint project between Sandvik Coromant and Toyota’s mobility brand KINTO.

Read More

The 8th WZL Gear Conference

July 21-22. Itasca, IL. For more than 50 years the annual WZL Gear Conference in Aachen, Germany, has been fostering technical collaboration and communication among the members of the WZL Gear Research Circle. Sixteen years ago, exclusive contents of the Aachen gear conference were first presented in the USA. Reishauer is honored to be a part of this tradition and to host: The 8th WZL Gear Conference for North America. This technical forum will provide the opportunity for North American Companies to connect with WZL and learn about current research activities.

Register Today