Low-Pressure Carburizing (LPC): The Affordable Alternative to Gas Carburizing

Gas carburizing has been around for a long time and is possibly the most common heat-treating process. Low-pressure carburizing (LPC) has proven to be a much cleaner and very capable alternative process. As the world establishes strong environmental, social, and governance (ESG) policies, electrically heated options with no endothermic gas emissions are really at the forefront of this trend. The heat-treat community will need to adjust. In addition to less harmful emissions, an added benefit of LPC is that it offers a comfortable, cool, and clean work environment for employees. The goal is to break the myth that LPC is only for aerospace or special applications and that it is not affordable. Mark Hemsath from Nitrex helps us dig deeper into gas atmosphere carburizing versus LPC.

Techniques and Equipment Types to Harden Gears

Learn about the processes and furnaces used for the ideal gear heat treating solutions. Review case studies and analyze cost in this presentation by Ben Bernard from Surface® Combustion, Inc.

Heat Treat Solutions with ECM Advanced Automation

The commercial heat treater’s solution to staffing turn-over and availability? ROBOTICS! Advanced automation & robotic solutions by ECM solve challenges met everyday in the CHT environment. Workload building, dunnage handling, furnace loading/unloading (and more) are all possible when you partner with ECM - we’re more than a furnace company.

Read More

Vacuum Gas Nitriding: Gears

Vacuum gas nitride processing from Solar Atmospheres can significantly increase the fatigue strength and service life of your parts. Benefits include case depths up to 0.025” and improved wear and anti-galling properties due to a 40 - 70% increase in surface hardness. Corrosion resistance is increased through nitrogen-enrichment.

Read More

Built-for-Stock—Fast Delivery of UBQ Batch Furnace

AFC-Holcroft's innovative Built for Stock program offers us the ability to deliver equipment weeks or months earlier than typical build-to-order delivery. Best of all, there is no extra cost for this accelerated delivery. This program features popular equipment such as batch furnaces, EZ endothermic gas generators, and support equipment.

Read More

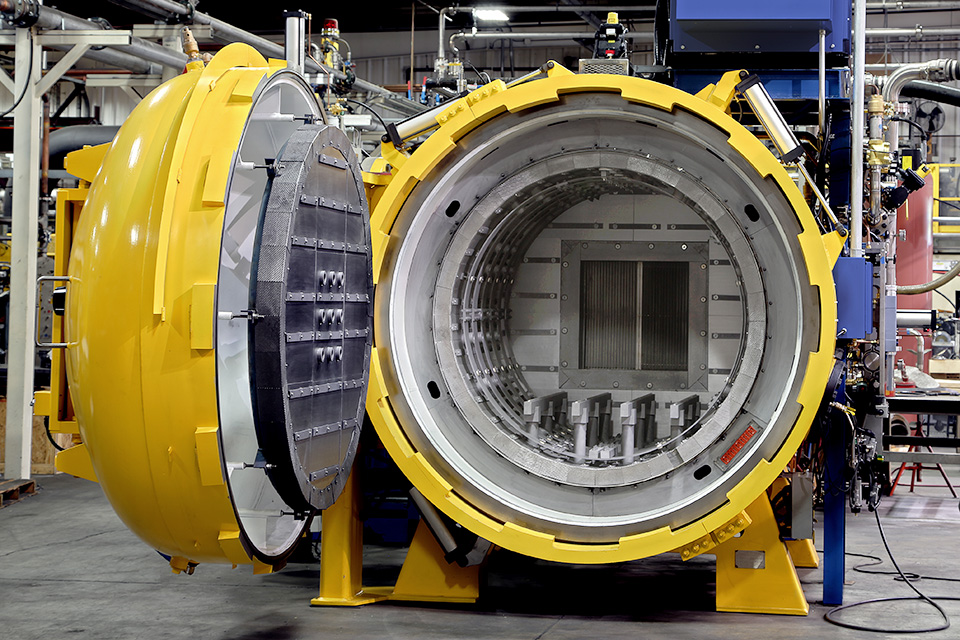

High Pressure Quench Vacuum Carburizing Furnaces

Get fast, forceful gas cooling with Solar Manufacturing’s IQ series of vacuum carburizing furnaces. It’s high performance internal quench system with direct-exit, sliding radiation baffles is the least restricted gas flow path on the market for superior hardening at quench pressures up to 20 bar.

Contact us to learn more about our vacuum furnace ingenuity.

P: 267.384.5040

Read More

Increase Profitability with Lights-Out Automation Systems

Manufacturing is changing. That statement has always held true. But now, more than ever, we are seeing new technologies, new demands, and new ways of thinking with regards to the factory of the future. These new demands include shorter part runs, cheaper products, and increased flexibility on the shop floor—all while dealing with a manufacturing labor crisis. Learn more in our webinar on May 25th at 2pm CDT.

Register Today

Helios Gear Introduces Deburring Machine

The Helios TM 250-CNC machine from Tecnomacchine brings together two fundamental strategies that empower manufacturers to deburr gears more productively. “For many job shops, smaller lot sizes and a higher mix of part numbers make a fully automated solution difficult to justify,” said David Harroun, vice president of Helios Gear Products. “But with the right feature set, such as the TM 250-CNC, manufacturers can deburr gears more profitably than ever before.”

Read More