All-Directional Y-Axis Turning

Sandvik Coromant, a cutting tool and tooling system specialist, has introduced a new method for turning complicated shapes and pockets with a single tool. Y-axis turning offers benefits such as reduced cycle time, improved component surface quality and more stable machining.

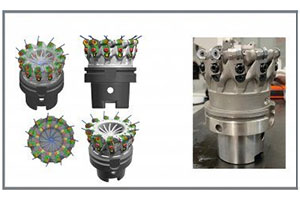

Seco Tools 3D Manufacturing Creates New Opportunities

Additive manufacturing, or 3D printing, allows Seco Tools to create products that would otherwise be difficult or impossible to manufacture. The advantages include shorter lead times, improved tool life and increased sustainability.

West Ohio Tool Expands Opportunities with WBE Certification

West Ohio Tool, one of America’s leading manufacturers of custom-designed carbide, polycrystalline diamond (PCD) and cubic boron nitride (CBN) tooling, continues its growth and market expansion with the acquisition of several certifications that benefit women-owned businesses.

Game Changers: Hamai N70 Horizontal Hobbing Machines

The Hamai N70 Series offers the worldclass speed, accuracy and dry hobbing productivity you need for fine pitch and super fine pitch hobbing– at a price you can afford. Models equipped with Fanuc 31i series CNC, direct drive and torque motor tables and hob head with 6000 RPM max; available for parts as large as 70 mm diameter x 200 mm long tooth sections max 2.5 Module. With or without automation.

Only from Machine Tool Builders

Save Time and Money with Precision Spindle Repairs

PDS provides manufacturers with better-than-new spindle repairs for precision machining applications. Specializing in metalworking spindle rebuilds for Milling, Turning, Grinding, Reaming, Drilling, Tapping, Boring, and Routing applications. PDS customers typically save up to 50% of the cost of new spindles. Contact PDS for 3-5 day spindle repair. Call 704-922-1206.

Or Visit

Vacuum Carburizing Versatility

Surface® Combustion offers a complete line of vacuum carburizing furnaces. The Vacuum Allcase® with integral oil quench mates with existing gas atmosphere Allcase furnace lines. The Multi-chamber Cloverleaf™ Vacuum Carburizing system includes both high pressure gas quench and oil quench options. The Gas-Fired SoftVac™ furnaces can be used for long carburizing cycles with reheat and quench operations.

Read More

One-Stop Solution Provider for all Blasting & Peening Requirements

Sinto Surface Technologies business is comprised of National Peening, Inc. and Technical Metal Finishing. Throughout the United States, there are six service centers that provide a variety of finishing services across a wide range of part sizes and configurations, from small springs and pins to single components weighing 50,000 lbs.

Read More

Process optimization for gear skiving

The optimization of tool life and setup times helps stabilize manufacturing costs and delivery performance. Liebherr not only provides high-quality gear skiving tools with precision but also offers support in optimizing your manufacturing processes. The machine, tools, application, and service allow for professional assistance from the initial inquiry to process maturity.

Read More

oelheld’s DiaGrind: Increased Productivity & Cost Efficiency

Conquer your gear manufacturing challenges with oelheld’s DiaGrind series. Increase grinding wheel and cutting tool life, reduce grinding burn and burrs, gain excellent air release properties, and achieve machine cleanliness – all with DiaGrind. Successfully used on gear hobbing, grinding and shaping applications.

Read More

Technology for Gear Solutions

Miba Sinter Group is the technology leader in powder metal applications offering a wide variety of production processes. Semi-finished (near-net) blanks finalized by partner gear manufacturers deliver reduced machining time, waste, and costs. Net-shape spur and helical gears with NVH performance, high strength and precision, and cost-optimized design and production.

Read More

STAR NXT HOB SHARPENING

The Star NXT sharpens both straight and spiral gash hob design up to 8” OD x 10” OAL, as well as disk, shank, and helical type shaper cutters, Scudding® and skiving cutters, and a wide range of round tools making it a versatile tool room machine.

LEARN MORE

LPC: Take the alternate route to low carbon carburizing

America is the place where legends are born. Just as the legendary Route 66 evokes the spirit of adventure, opportunity, and experience, SECO/WARWICK Group likewise embodies this same spirit in pursuit of heat treatment excellence. Our environmentally responsible low pressure carburizing (LPC) furnaces are one way SECO/VACUUM provides better choices #Made4America.

Check out our vacuum solutions and explore your American journey with us.

Read More