[please visit our sponsor]

Worm Gears—Ask the Expert

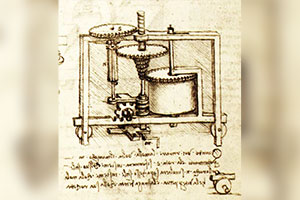

How does one determine the center of a worm and a worm wheel? Also, what are the differences between the common worm tooth forms?

From the Archive - Introduction to Worm Gearing

Worm gears are among the oldest types of gearing, but that does not mean they are obsolete, antiquated technology. The main reasons for the bad experiences some engineers have with worm gearing are misapplication and misuse. No form of gearing works for every application. Strengths and weaknesses versus the application must be weighed to decide which form of gearing to use. For proper application and operation of worm gears, certain areas that may differ from other types of gearing need to be addressed.

Our High Torque Gears Fill a Key Design Gap.

For over six decades, we’ve helped top engineers tackle tough gearing problems. Application industries include: Robotics, Aerospace, Defense, Transportation and Medical.

Learn how our gearing systems can be leveraged in your sector. Contact our engineers today at 320-762-7133.

for more information.

Download Case Studies Here>

Homogeneous quality assurance environment that leads to success.

WENZEL’s WM | Quartis software suite ensures that specializations and information silos will be a thing of the past. Whether your team is measuring on a CMM or GMM, ensure that every user seamlessly shares data across the entire plant, speeding communications and improving efficiency with this singular collection point.

Read More

Solar Atmospheres Now Offers Oil Quenching Capabilities

Solar Atmospheres provides low pressure carburizing (LPC) in vacuum to increase the surface hardness/strength of gearing for improved friction and wear. LPC delivers clean parts with less distortion reducing post process finishing operations, and costs. For lower hardenability alloys and/or to attain higher core hardness on gears, Solar now offers vacuum oil quenching!

Read More

White Paper: NVH Optimization and Production Tolerances

Are you looking to optimize NVH performance and sustainability in your gearboxes? Read this white paper and gain insights into software-driven analyses with the FVA-Workbench and practical strategies for achieving longevity and smooth operation. Explore the transformative potential of detailed gear system analyses, flank modification design, and manufacturing tolerance considerations.

Access White Paper

SIGNATURE DOUBLE ENVELOPING TORQUE, IN A COMPACT WORM DESIGN

Cone Drive’s Double Enveloping worm gearing has been supplying the industry with more torque since 1925. We fully support our worm with two input bearings allowing you to mount the gearbox in any position.

We understand the cost of downtime and provide best in class lead times to keep you in motion.

Read More

BEARING WORLD: 25-26 June, 2024 in Würzburg, Germany

Discover new bearing trends as Prof. Gerhard Poll of Leibniz University Hannover and Prof. Bernd Sauer of The University of Kaiserslautern-Landau kick off the 5th international BEARING WORLD conference. Followed by keynotes from Dr. Michael Pausch of Schaeffler Technologies, Freddy Hernandéz of SKF, and Dennis Labisch of FUCHS LUBRICANTS Germany.

Tickets Available Here

Heat Treat Solutions for Every Industry

SECO/VACUUM designs a wide range of innovative vacuum furnaces for heat treating processes spanning many industries. Technologies include vacuum carburizing, high pressure gas quench, single-piece flow 4D quench, high speed vacuum carburizing, nitriding, and more.

See what SECO/VACUUM can do for your industry!

Read More

NGC Enhances Gearbox Manufacturing With EndoFlex From UPC-Marathon

NGC Gears, one of the world’s largest wind power gearbox manufacturers, has completed the installation of two additional EndoFlex generators from UPC-Marathon, a Nitrex company, at its new facility in Jinhu, China location. This acquisition brings the total of generator sets to five since 2022, collectively generating an impressive 800 m³/h (22,252 ft3/h) capacity of endothermic gas supplied to carburizing and hardening furnaces used for processing various gear components.

Read More

AGMA Wins First Place in Trade Show Award for MPT Expo

The American Gear Manufacturers Association (AGMA) was presented with the Trade Show Executive’s Fastest 50 Grand Award in the “Fastest-Growing Show by Percentage Growth in Total Attendance in 2023” category on May 9 at the Fastest 50 Awards & Summit in Las Vegas.

Read More