Customize Gear Skiving for Precise, Efficient Gear Cutting

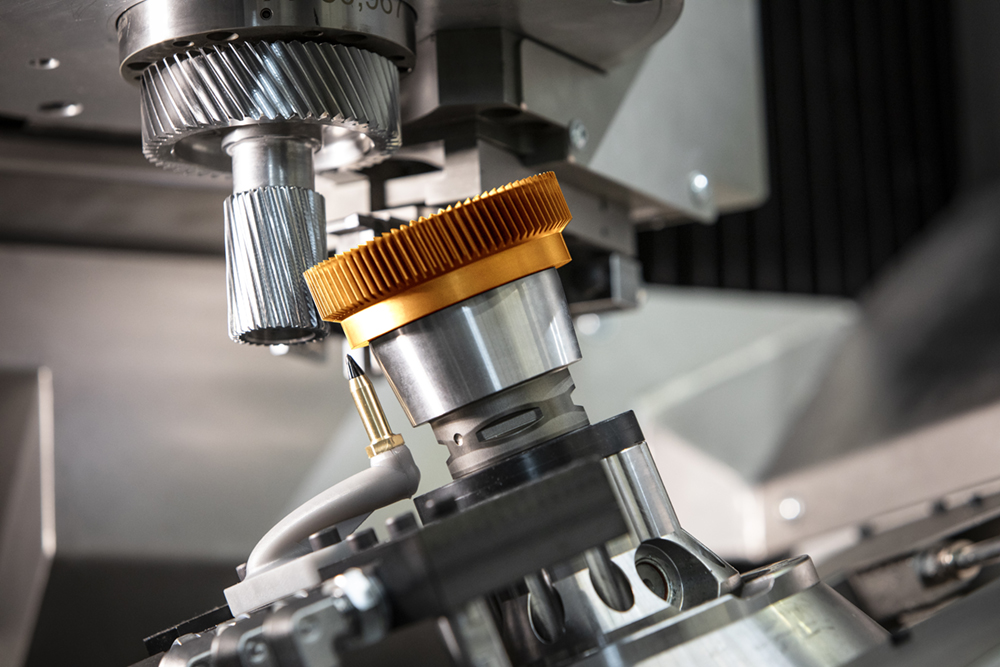

Gear skiving on a mill-turn machining center with fully synchronous spindles is highly efficient, fast, and accurate. In some cases when producing small and medium-sized volumes, gear skiving will gradually replace established gear-cutting processes.

Investigation of the Manufacturability of Topological Modifications Using Adapted Kinematics for Gear Skiving

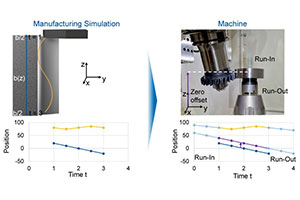

Gear skiving is used for both soft and hard finishing. As a quality critical final step in hard finishing, the process can be used to create modifications to the tooth flank. At present there is no knowledge of the extent to which topological modifications can be applied by gear skiving. In this report, the feasibility of manufacturing topological modifications on an external gear through adapted kinematics for gear skiving has been investigated.

White Paper: NVH & Production Tolerances | Optimized Gearbox Design - Read it Now

Gear up! This white paper uncovers how production tolerances can enhance NVH performance and sustainability. Discover the power of software-driven analyses using the FVA-Workbench to achieve durability and smooth operation. Explore the transformative possibilities of detailed gear system analyses, flank modification design, and manufacturing tolerance considerations.

GMTA – Systems solution provider for the gear industry

New Profilator S300 machine

- Flexible modular machine platform (skiving, hobbing, pointing, cycloidal milling, chamfering and deburring)

- Single or Twin spindle platforms available

- Optional tool changer turret for maximum machining flexibility

- Siemens One with conversational part programming

- Easy setup and access due to open walk-in work area

Read More

Find Your Passion at IMTS

Manufacturers come to IMTS, The International Manufacturing Technology Show, to connect, find inspiration, and discover solutions. Join us at McCormick Place in Chicago, September 9-14, 2024.

Find Your Passion at IMTS

Equipped for everything: gear skiving with LK 280 DC

Elevate your machining precision with the LK 280 DC gear skiving machine. The integrated FlexChamfer chamfering unit removes sharp edges and burrs arising from tool runout, ensuring impeccable finishes. Experience seamless operations and enhanced efficiency with this all-in-one solution for chamfering during the machining process.

Read More

NIDEC has gear machines in stock. Prepare for growth!

Get ready for the predicted growth for the gear industry in the second half of 2024. Upgrade your efficiency, production and capacity with NIDEC's quality, reliability and precision. NIDEC Machine Tool America has hobbers, shapers and gear grinders available for nearly instant delivery. Call Scott Knoy today at 248-756-5017.

Read More

DVS AMERICA presents the SynchroFormV - Gear Skiving and Hard Finishing in One Machine

The vertical machine concept for precise skiving and internal honing with 1 or 2 spindles, automation, depending on your flexibility and quantity needs. From automotive to greentech, from prototyping to serial production: Präwema SynchroFormV: Quality made in Germany.

Read More

Power Skiving for Workpieces with Interfering Contours

Specifically designed for the economical production of EV gears with interfering contours and internal gears, also highly suitable for shaft-type parts, Gleason provides Power Skiving Machines with different options, including optional gear hobbing, cutting of internal gears with a swing diameter of up to 240 mm, or even integrating tool resharpening in the manufacturing process.

Read More