|

Get the freshest updates on gear technology

|

|

|

|

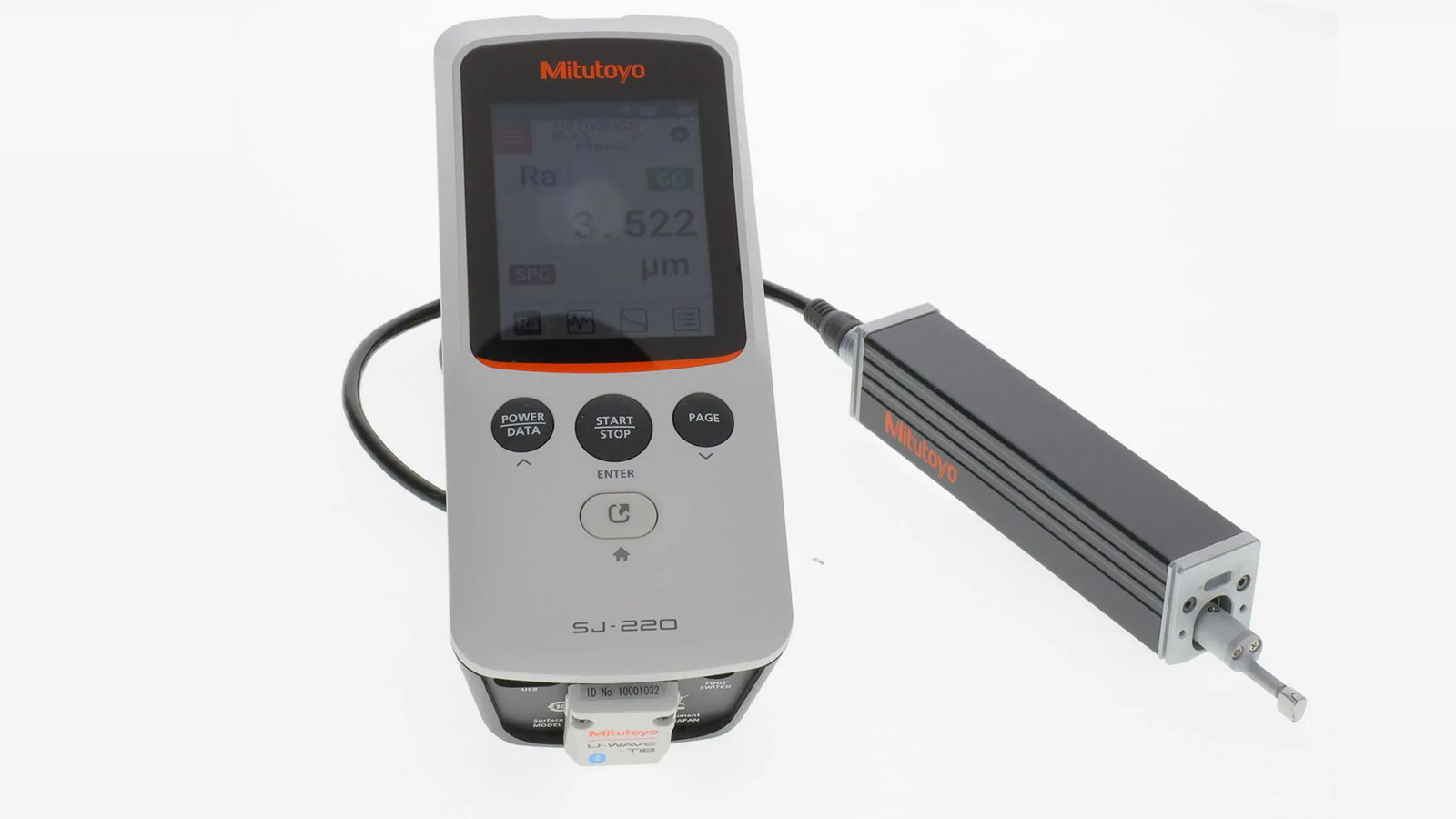

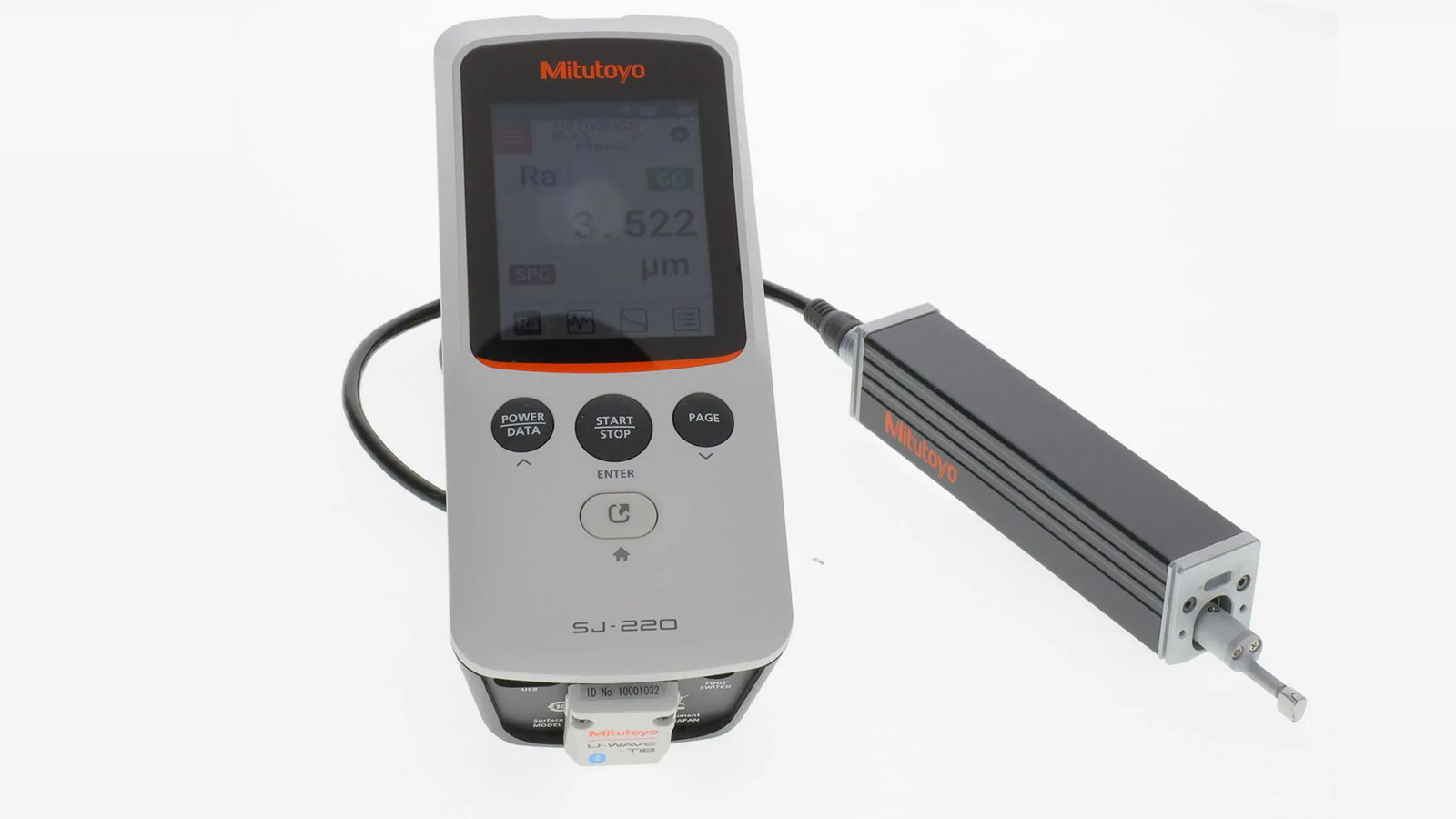

| Mitutoyo America Corporation Releases New SJ-220 Portable Surface Roughness Tester |

Mitutoyo America Corporation, a leading manufacturer of precision metrology instruments and solutions, announced the release of the new Surface Roughness Tester SJ-220 Series to its vast line of form-measuring instruments. This product provides compatibility and versatility to meet the diverse needs of manufacturing sites.

|

| [Sponsored Content] |

|

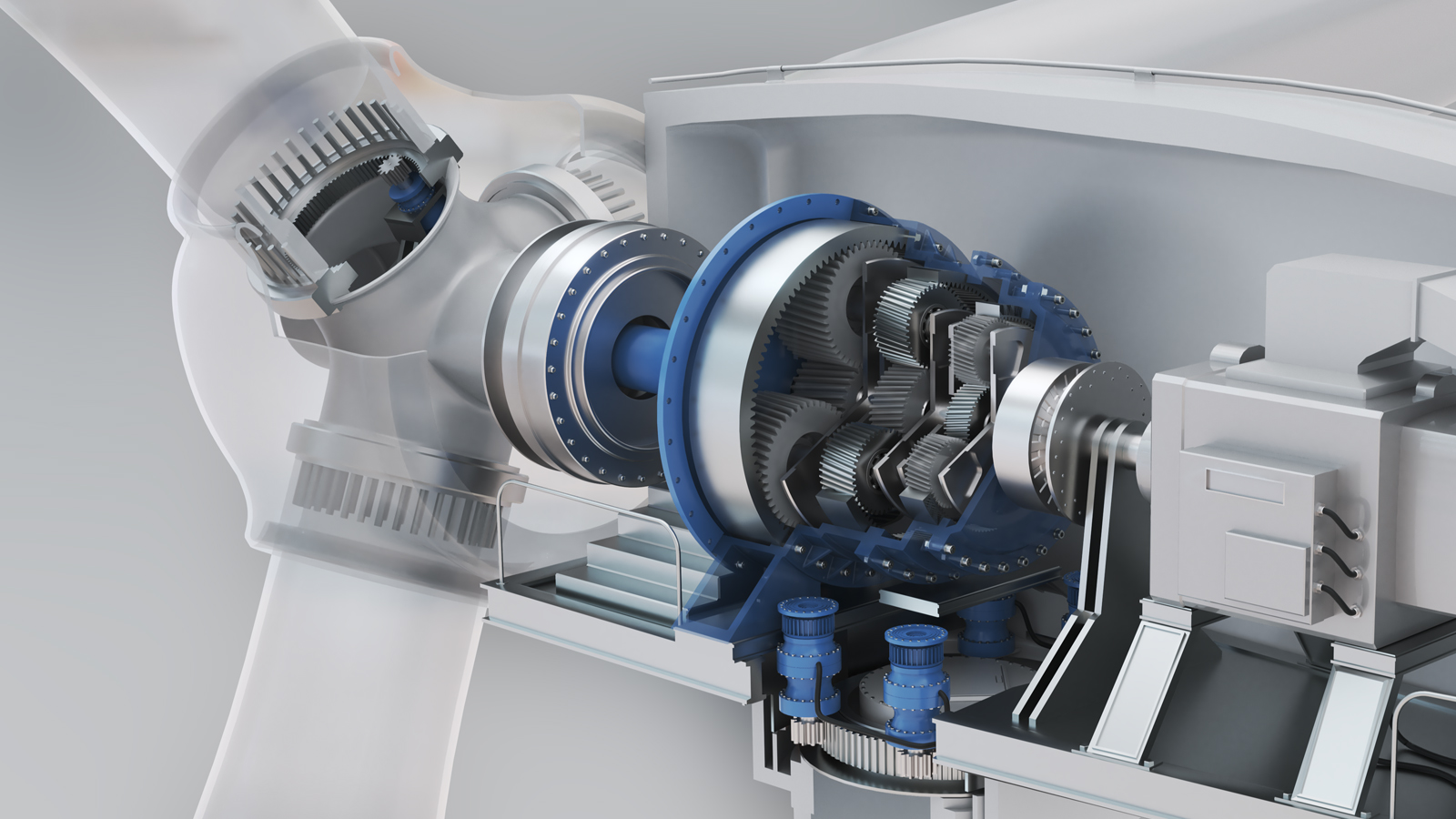

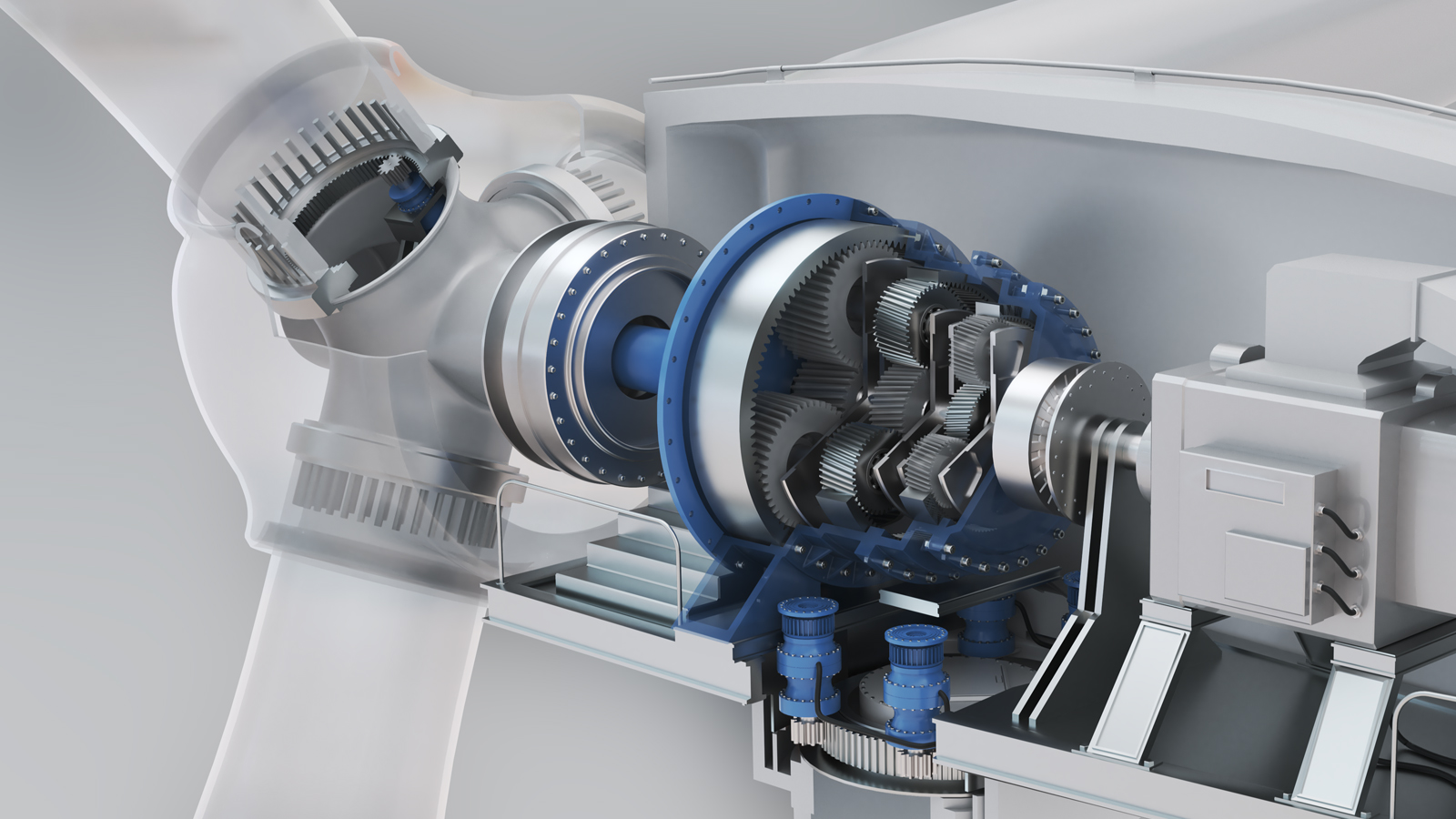

| How machine learning improves the surface quality of ground gears |

Discover how machine learning minimizes roughness variations in profile grinding, enhancing the performance and durability of wind power gearboxes. The latest research by KAPP NILES demonstrates an optimized dressing process that improves surface quality on tooth flanks after profile grinding for next-generation wind turbines.

|

| [Sponsored Content] |

|

| Boost Mold Quality with Advanced CT Techniques |

Injection molding bridges prototyping and full-scale production with its unmatched scalability and precision. By integrating CT technology, manufacturers gain clear insights into mold accuracy and material behavior—accelerating the path from design to high-volume, defect-free plastic parts.

Take your parts from prototype to production without compromise. Injection molding delivers the precision and repeatability needed for scale, while CT integration ensures every mold and material meets spec—enabling smoother transitions and consistent quality at volume.

|

|

|

| Green Vacuum Furnaces for Precision Heat Treatment |

Surface® Combustion’s vacuum furnaces deliver bright finishes with minimal distortion while reducing emissions and maximizing energy efficiency. With 100+ years of expertise, we’ll help you achieve sustainable, high-quality heat treating. Contact us to learn more.

|

|

|

| All in-stock NIDEC gear machines in the US |

… will NOT be subject to tariff related price increases. Act now, reduce uncertainties in global economics and lock in today’s price. This includes gear hobbers, gear shapers, gear grinders as well as in-stock Federal Broach machines. You can count on NIDEC Machine Tool America. Call Scott Knoy today at 248-756-5017.

|

|

|

| Inspection at Nano Level |

Introducing the 175GMS nano – a compact, high-precision platform for advanced gear inspection. It analyzes cylindrical, bevel, and worm gears, shafts, epicycloids, cutting tools, and more. Ideal for fine-pitch gears down to 0.15 module, it features automatic skidless surface finish analysis and advanced waviness tools for profile, lead, and pitch – all powered by cutting-edge, industry-proven GAMA™ software.

|

|

|

|

| Precision Gear Measurement with Liebherr WGT |

The Liebherr WGT series delivers high-precision gear inspection for gears, shafts, and tools. Featuring granite guides, air bearings, and Renishaw probe systems, it ensures lasting accuracy. The user-friendly LHInspect software enables efficient measurements to VDI/VDE standards—perfect for automotive, aerospace, and mechanical engineering applications.

|

|

|

| AGMA and ABMA Form Motion and Power Manufacturers Alliance |

On April 24, at the AGMA/ABMA Annual Meeting in Austin, TX, the membership of the two associations voted to approve a merger between the American Gear Manufacturers Association (AGMA) and the American Bearing Manufacturers Association (ABMA), creating the Motion and Power Manufacturers Alliance (MPMA). The new organizational structure began May 1, 2025.

|

|

|

|

| |