|

Get the freshest updates on gear technology

|

|

|

|

| From the Archive: Super-Reduction Hypoid Gears |

Super-reduction hypoid gears (SRH) are bevel worm gears with certain differences regarding hypoid gears. If two axes are positioned in space and the task is to transmit motion and torque between them using some kind of gears with a ratio above 5 and even higher than 50, the following cases are commonly known.

|

|

| From the Archive: Relationship Between Wear and Pitting Phenomena in Worm Gears |

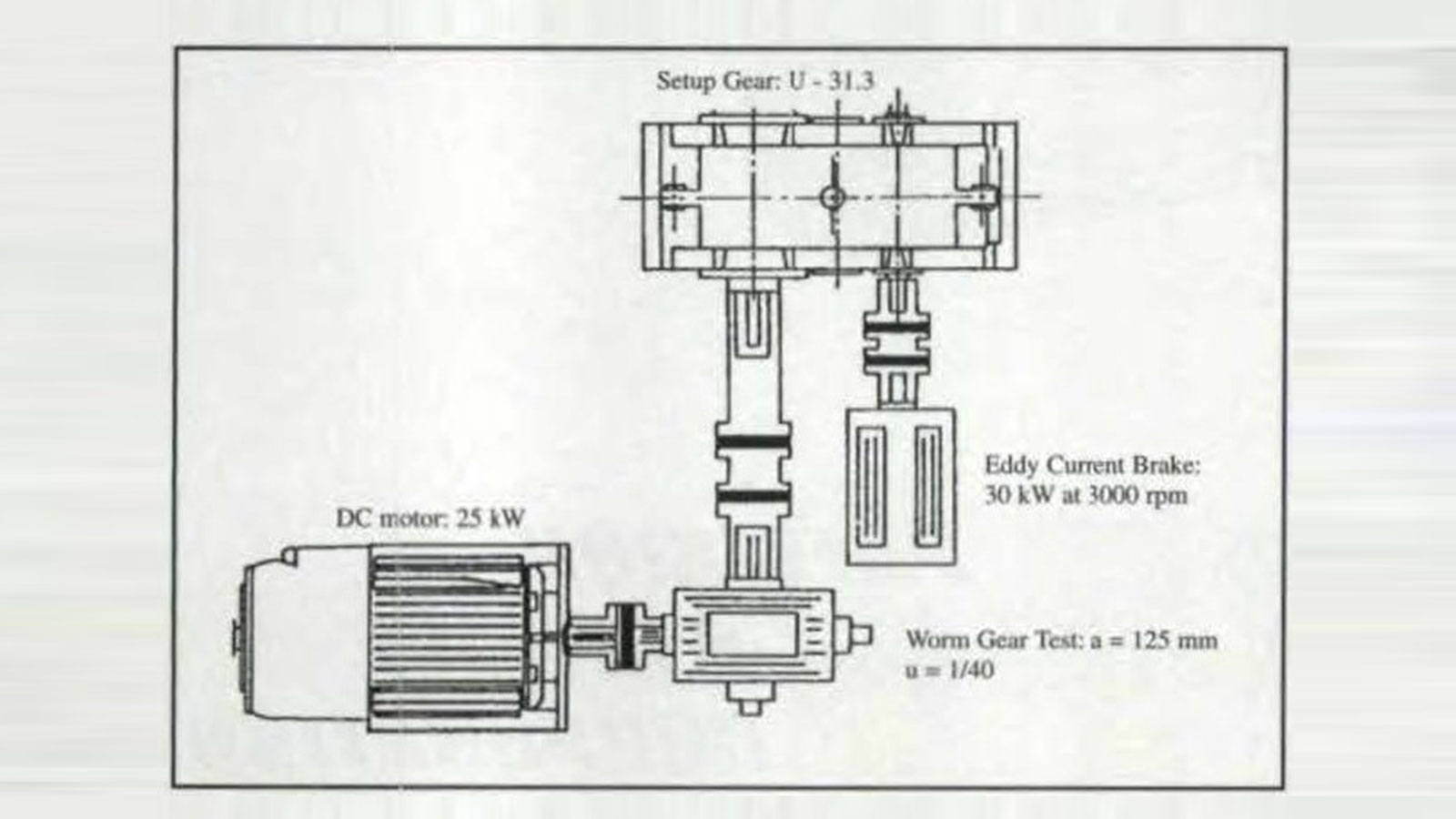

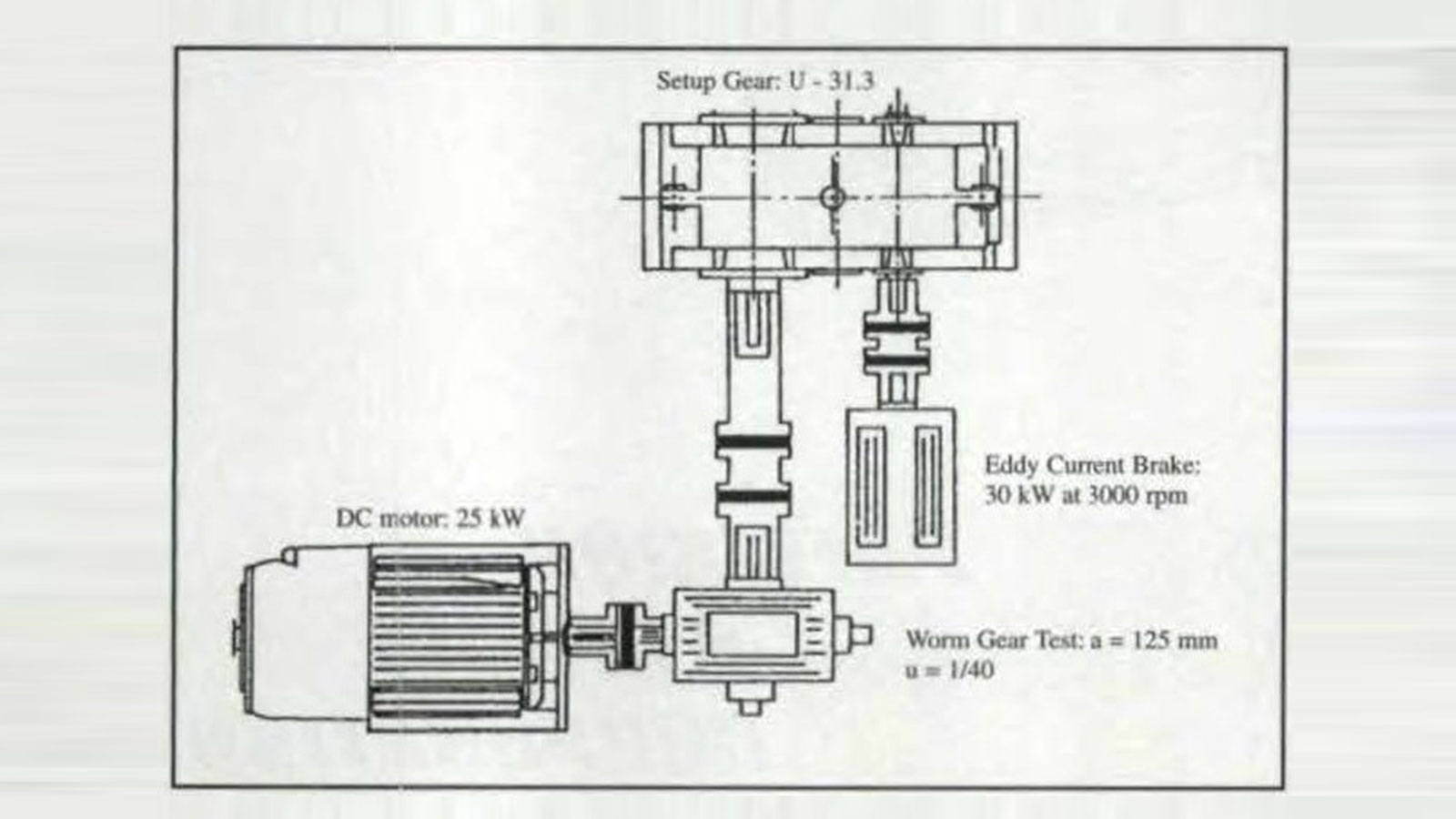

Worm gears display unique behavior of surfaces because of the presence of wear phenomena in addition to contact pressure phenomena.

|

| [Sponsored Content] |

|

| Unlock Innovation: Secure Your Spot at MPT Expo 2025! |

Registration is OPEN for Motion + Power Technology Expo — October 21–23, 2025 in Detroit! Discover the latest tech, meet industry leaders, and get ahead with expert insights. Don’t wait — lock in Super Saver pricing by July 15 before rates go up!

|

|

|

| Vacuum Carburizing With Gas Quench And No Oil |

Low-Pressure Carburizing (LPC) is the future of case hardening, and many materials can be carburized and quenched without oil. The versatile Vector® high pressure gas quench vacuum furnace from SECO/VACUUM handles a wide range of heat treatment processes including LPC and Low-Pressure Nitriding (LPN).

|

|

|

| Our High Torque Gears Fill a Key Design Gap. |

We’ve helped top engineers tackle tough gearing problems for over six decades. Application industries include Robotics, Aerospace, Defense, Transportation, and Medical.

Learn how our gearing systems can be leveraged in your sector. Contact our engineers today at 320-762-7133

|

|

|

| 100 Years of American Precision. Custom Gearing Solutions. |

For 100 years, Cone Drive has engineered American-made gearing solutions with unmatched precision and reliability. We offer custom solutions across our full range of technologies: double-enveloping worm gears, harmonic strain wave gearing, cycloidal gearing, and slewing drives and bearings. Count on Cone Drive for tailored motion control—designed, built, and trusted in the USA.

|

|

|

|

| AFC-Holcroft is Focused on Sustainability |

At AFC-Holcroft we are focused on improving energy efficiency and offering cleaner energy sources to our customers. This involves optimizing process parameters to minimize energy consumption, gas fired burner recuperation and waste heat recovery. Our customers can also realize additional benefits from investing in energy-efficient refractory materials and alternative heating methods.

|

|

|

| CT Insights: Boosting Injection Molded Part Quality |

Injection molding enables the efficient creation of intricate plastic parts—from consumer goods to industrial components. When paired with CT technology, it empowers manufacturers to inspect internal structures, detect defects early, and fine-tune processes for higher precision and productivity.

From LEGO bricks to cutting-edge devices, injection molding delivers precision at scale. Now, with CT analysis, manufacturers can catch defects before they escalate, optimize every cycle, and drive smarter, faster production—bringing unmatched reliability to every molded part.

|

|

|

| Smarter bevel gear design with the FVA-Workbench |

Unlock up to 30% better flank utilization. The FVA-Workbench combines deformation analysis, geometry design, and load capacity checks in a single system. Design bevel and hypoid gears based on real system behavior, not just assumptions. No tool switching, no third-party licenses: just faster, smarter gear development in one seamless workflow.

|

|

|

|