Hobbing and Chamfer Cutting: Efficient, Flexible Gear Manufacturing on a Single Machine

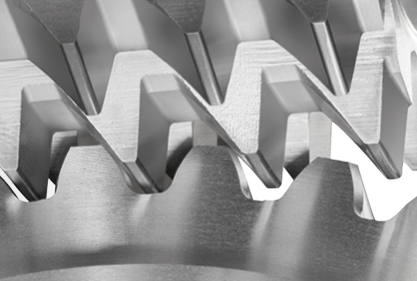

It wasn’t long ago that cylindrical gear chamfering and deburring was almost an afterthought. Now the process ranks as high in importance as hobbing, shaping and grinding. Seemingly every gear manufacturer, particularly those developing transmission gears for e-drive applications, recognizes that anything less than a flawless tooth flank can result in premature transmission failure, less-than-optimal efficiency, and unacceptable noise. Thus, generating a chamfer to precise customer specifications is critical to minimize the potential for sharp, brittle edges after heat treat; avoid edge load situations in the gearbox; and eliminate excessive stock and hardened burrs in the tooth flank prior to the hard finishing operations (conditions which can greatly diminish tool life).

Machine Tool Builders: Your One-Stop Shop

Take your production to the next level with Machine Tool Builders’ world-class lineup of new gear manufacturing technologies, featuring: horizontal and vertical hobbing, generative & profile grinding, chamfer/deburr & inspection, plus the industry-leading rebuilds, retrofits and service that we’ve built our reputation on since 1995.

Read More

Universal chamfering application: A chamfer for every gear

When chamfering internal gears on ring gears or cluster gears with interfering contours, the available procedures often reach their limits. This is where the universal chamfering solution by Liebherr comes in: A tapered end mill, mounted directly on the machining head, means that a chamfer is possible on practically any gear.

Read More

Experience the Power of Nano Inspection

Imagine evaluating waviness on a sub-micron level. Gear inspection solutions can enhance productivity with a single compact platform for the inspection of gears – even fine pitch gears smaller than 0.2 modules! Discover technology like Gleason’s GMS nano series Sept. 12-17 at IMTS 2022 in Chicago.

Read More

Hobbing and Chamfering: Better Together

Chamfer Hobbing is now available up to Module 5.0 – in parallel to gear hobbing! With Genesis® 280HCD Gear Hobbing Machine, the many benefits of Gleason’s revolutionary Chamfer Hobbing process are now available for a wider range of applications, including larger automotive, truck and industrial gears.

More Information

A perfect inventory is just 10 steps away.

The best gear manufacturers want a perfect inventory. Download the 10 Inventory Must Do’s for Small to Medium-Sized Manufacturers whitepaper today and let good inventory management take you to better, brighter days.

DOWNLOAD >>

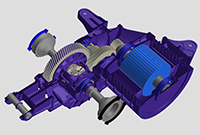

Hexagon Offers ePowertrain Webinar Series

Hexagon offers a three-part E-mobility webinar series highlighting the use of engineering simulation tools and methods to rapidly evaluate numerous ePowertrain designs. This webinar series will showcase how an EV gearbox is designed from scratch and developed to meet design requirements.

Read More