Internal Gearing, Deburring, Honing and the Advancement of Robotic Cells

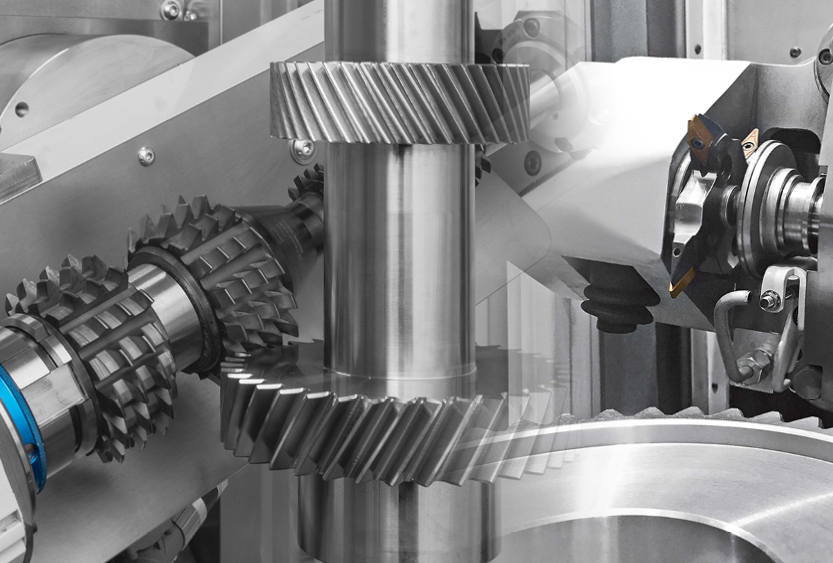

The electrification movement is in full swing despite many obstacles still in play. Regardless of these challenges, machine tool providers are expanding their machine operations and tooling capabilities to meet the e-mobility demands of the future. VarioChamfer, the new, patented process from Präwema enables skiving and deburring in a single clamping when manufacturing gears, thus significantly increasing production efficiency.

Hobbing and Chamfer Cutting

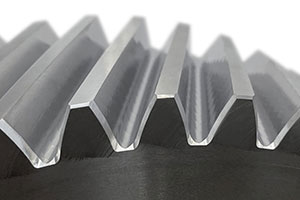

It wasn’t long ago that cylindrical gear chamfering and deburring was almost an afterthought. Now the process ranks as high in importance as hobbing, shaping and grinding. Seemingly every gear manufacturer, particularly those developing transmission gears for e-drive applications, recognizes that anything less than a flawless tooth flank can result in premature transmission failure, less-than-optimal efficiency, and unacceptable noise. Thus, generating a chamfer to precise customer specifications is critical to minimize the potential for sharp, brittle edges after heat treat; avoid edge load situations in the gearbox; and eliminate excessive stock and hardened burrs in the tooth flank prior to the hard finishing operations (conditions which can greatly diminish tool life).

One-Stop Solution Provider for all Blasting & Peening Requirements

Sinto Surface Technologies business is comprised of National Peening, Inc. and Technical Metal Finishing. Throughout the United States, there are six service centers that provide a variety of finishing services across a wide range of part sizes and configurations, from small springs and pins to single components weighing 50,000 lbs.

Economic or Flexible Chamfer Cutting of Gears? Both.

Gleason offers stand-alone or fully integrated chamfer cutting technologies: Chamfer Hobbing, ideally suited for precise and economic chamfering of high volume automotive and light truck lots; and Fly Cutter Chamfering, delivering exceptional flexibility for lower volume jobber applications.

Learn more

Gear cutting and chamfering parallel to machining

The gear hobbing machine LC 500 DC integrates the ChamferCut device on the operator side. This setup allows the machine operator to have unobstructed access to both machining positions. The Liebherr ringloader concept ensures efficient workpiece transfer between gear hobbing and chamfering, enabling parallel processing. Corrections and adjustments for varying flank corrections can be made using the user-friendly software.

Read More

A tailored solution for your measuring needs

WENZEL has been manufacturing metrology systems since 1968! Our new gear software bridges the gap our customers face and offers a common platform for both gear metrology and traditional inspection. Regardless of what you use, a traditional stand-alone CNC gear tester or a CMM-based gear inspection system, WENZEL has the solution for you.

Read More

Game Changers: Hamai N70 Horizontal Hobbing Machines

The Hamai N70 Series offers the worldclass speed, accuracy and dry hobbing productivity you need for fine pitch and super fine pitch hobbing– at a price you can afford. Models equipped with Fanuc 31i series CNC, direct drive and torque motor tables and hob head with 6000 RPM max; available for parts as large as 70 mm diameter x 200 mm long tooth sections max 2.5 Module. With or without automation.

Only from Machine Tool Builders

A reliable partner for power transmission critical gears and bevel sets

CATTINI, a leading Italian gear and bevel sets manufacturer with one of the broadest custom gear production capabilities in the industry, is now proud to be serving the Americas. Many multi-national heavy-duty vehicle and machinery OEMs have been choosing Cattini for years.

Read More

Solar Atmospheres Now Offers Oil Quenching Capabilities

Solar Atmospheres provides low pressure carburizing (LPC) in vacuum to increase the surface hardness/strength of gearing for improved friction and wear. LPC delivers clean parts with less distortion reducing post process finishing operations, and costs. For lower hardenability alloys and/or to attain higher core hardness on gears, Solar now offers vacuum oil quenching!

Read More

Zero Carbon Target?

Induction is an eco-friendly heating method, as it does not generate carbon during the heating process. The electrification of the automobile and the manufacturing goal of a zero-carbon target process makes induction the perfect solution for heat treating, tempering, brazing, forging, and shrink fitting.

Read More

Sandvik Coromant at the Forefront of Automotive Metal-Cutting Research

Global leader in metal cutting Sandvik Coromant has announced its participation in Rota 2030, a federal government program designed to support and boost Brazil’s automotive sector. The company will contribute to R&D projects on an ongoing basis to educate the next generation of talent, establish fiercer competition among automakers and ensure the continued development of cutting-edge technologies and processes.

Read More

VBN Components' New Machine Shortens Delivery Times and Improves Material Properties

VBN Components AB in Sweden manufactures extremely wear-resistant materials and is known for "the world's hardest steel," Vibenite 290, and "the world's first 3D-printed cemented carbide," Vibenite® 480. Since its inception in 2008, the company has focused on hard, additively manufactured alloys with unique properties. Additive manufacturing is often associated with faster lead times for both development and production, and now VBN has shortened the production chain even further.

Read More