[please visit our sponsor]

Heat-Treat Trends

By Joseph L. Hazelton, Contributing EditorThe U.S. heat treat industry is in the middle of a labor shortage. Here's a look at what companies in the industry are doing about it. Plus, a look at some other trends affecting the heat treating industry.

Gleason GX Series with Closed Loop: Finish First

Gleason Genesis® GX Series Threaded Wheel Grinding Machines

take high-volume, high-quality gear finishing to a new level, with features like single-tool setup, twist-controlled grinding and integrated automation. Gleason Closed Loop System networks a GMS® inspection machine directly to the GX for fast, reliable, automatic data corrections.

Read More

LEASE Your Vacuum Furnace - ECM Dual Chamber

The ICBP® Pitless Duo vacuum furnace by ECM (with two independent chambers separated by a vacuum-tight door) is now available to lease! Quenching can be oil (hot or cold) or gas (up to 20 bar). Perfect for carburizing, hardening, brazing, carbonitriding, and is AMS2750E compatible. Contact ECM today! 262.605.4810 www.ecm-usa.com

Read More

State-of-the-Art Gear Grinding Technology

Machine Tool Builders Inc. of Machesney Park, Illinois is the exclusive North American dealer for Burri Gear Grinding Machines and Wheel Dressing/Profiling Machines. Burri offers highly competitive solutions for

- High production generative gear grinding

- Automation and Quick-Change Workholding

- Profiling machines for generative and form wheels

- Machine Tool Builders (MTB) service & training support

Burri Gear Grinding Technology by MTB

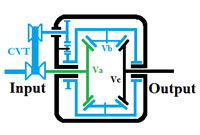

Introducing the NEW GEARBOX GENERATION - Licensing available

The new generation of gearboxes uses a differential.

- No more switching gears

- The motor can be kept running at constant speed, all the time

- Higher efficiency

- Even a small motor can produce a very high starting torque

- The system is reversible (dynamic braking)

- Cheaper to build

Read More

Free Webinar: 4D Quench - A Leap in Performance for Press Quenching

If you’re currently press quenching, you’ll want to attend this Webinar to learn about one of the most innovative developments in “press quench” technology. Say goodbye to oil quenching and hello to the environmentally friendly, cost effective technology of 4D high pressure gas quenching. Register for this SECO/VACUUM Webinar.

Register Today

Gear Nitriding in Vacuum

Vacuum gas nitride processing from Solar Atmospheres can significantly increase the fatigue strength and service life of your parts. Benefits include case depths up to 0.025” and improved wear and anti-galling properties due to a 40 - 70% increase in surface hardness. Corrosion resistance is increased through nitrogen-enrichment.

Read More