Two Newly Revised AGMA Standards

AGMA is pleased to announce the publication of two new revisions: ANSI/AGMA 2116-B24, Evaluation of Double Flank Testers for Radial Composite Measurement of Gears, written by the AGMA Gear Accuracy Committee, and ANSI/AGMA 6008-B24, Specifications for Powder Metallurgy Gears written by the AGMA Powder Metallurgy Committee. ANSI/AGMA 6008-B24 provides comprehensive details for the design, processing, and specifications of powder metallurgy, PM, steel gears that need to be agreed upon between the PM gear supplier and the purchaser. These include: definition of terms, gear tooth geometry considerations, inspection, PM gear materials, drawing specifications, heat treatment, and mechanical testing.

2024 Powder Metallurgy (PM) Design Excellence Awards Announced

The winners in the 2024 Powder Metallurgy (PM) Design Excellence Awards competition, sponsored by the Metal Powder Industries Federation (MPIF), demonstrate outstanding examples of PM’s diversity and ability to meet critical requirements. From electric vehicles to medical implants, once again, parts fabricators have demonstrated PM’s versatility and unique ability to challenge competing technologies. These award-winning components use PM’s flexibility to push forward new concepts and process controls to demonstrate the inexhaustible range of PM’s capabilities.

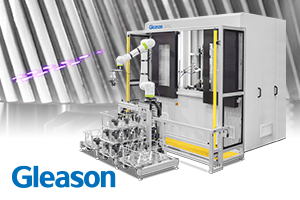

GRSL Quality Center: The Fastest Way to Quieter Gears

100% In-Process Quality Inspection for Low Noise Transmissions.Today, manufacturers take about 30 minutes to inspect and analyze a gear for NVH gear noise. Instead, the new GRSL Quality Center featuring laser inspection, optional roll testing, and Advanced Waviness Analysis for gear noise evaluation, gauges, measures and analyzes one gear in one minute, for up to 100% quality inspection of your production output.

Solar Atmospheres Now Offers Oil Quenching Capabilities

Solar Atmospheres provides low pressure carburizing (LPC) in vacuum to increase the surface hardness/strength of gearing for improved friction and wear. LPC delivers clean parts with less distortion reducing post process finishing operations, and costs. For lower hardenability alloys and/or to attain higher core hardness on gears, Solar now offers vacuum oil quenching!

Read More

BE THE CHAMPION WITH WINNING TECHNOLOGIES

SECO/VACUUM’s Heat Treat solutions put you in 1st place in the industry.

We lead the heat treat industry with more new technological innovations than any other manufacturer.

Our exclusive portfolio of all-vacuum technologies is engineered to run cleaner, cooler, and more efficiently. We support your success!

Read More

Surface® Combustion Vacuum Furnaces: All-Star Team

Our vacuum furnaces offer precision thermal heating for optimal process control. With over 100 years of experience, our engineers guide you to create the best heat treat system for your desired outcome.

Surface strong for over 100 years.

View our team line up at Surface Combustion