|

Get the freshest updates on gear technology

|

|

|

|

| In Memoriam: Barney Berlinger (1937–2025) |

The gear and motion control industry mourns the passing of Barney Berlinger, founder of ASI Technologies and longtime contributor to the American Gear Manufacturers Association (AGMA). A respected engineer, entrepreneur, and leader, Barney’s impact on the industry spanned decades and will not be forgotten.

|

|

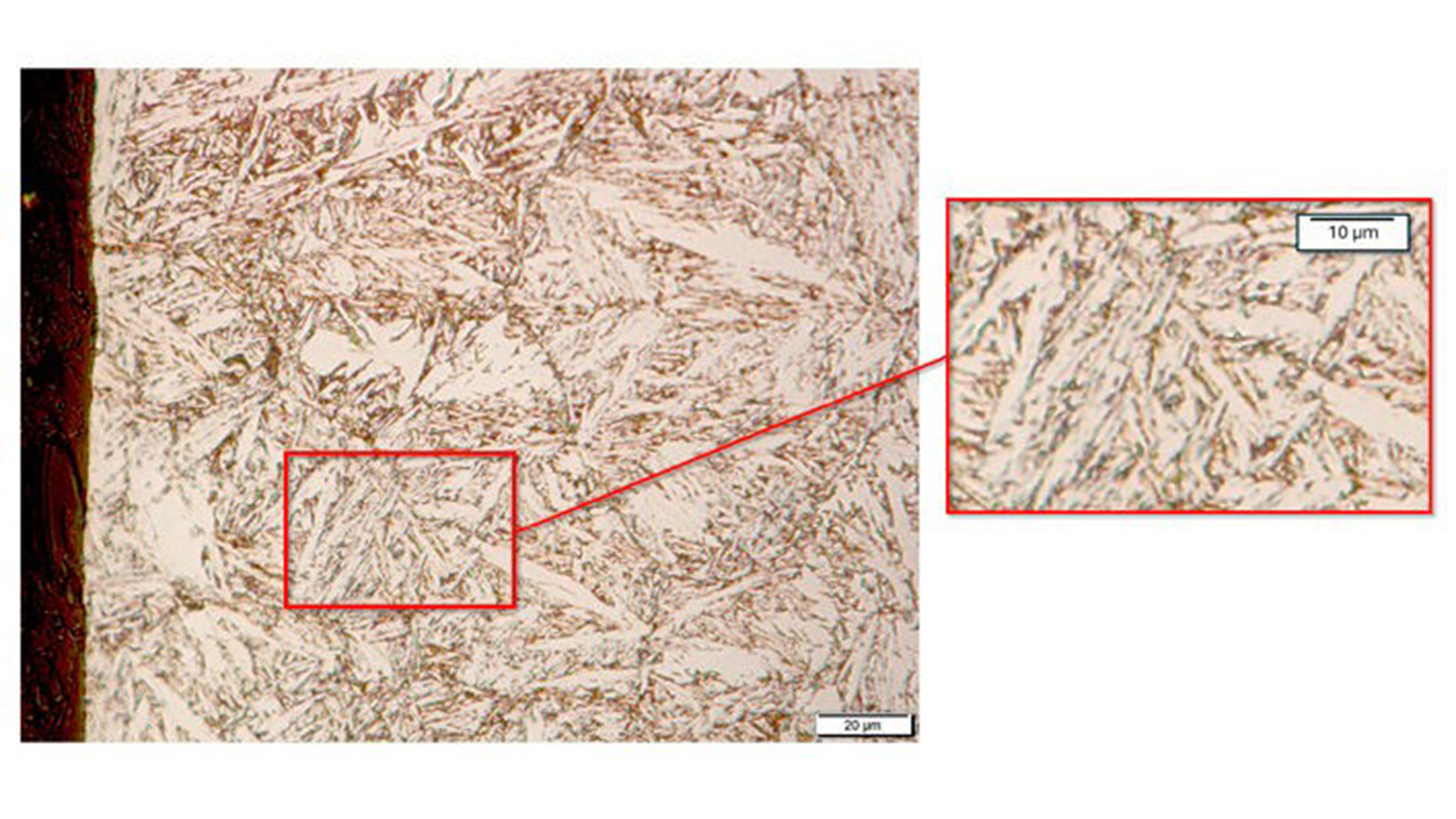

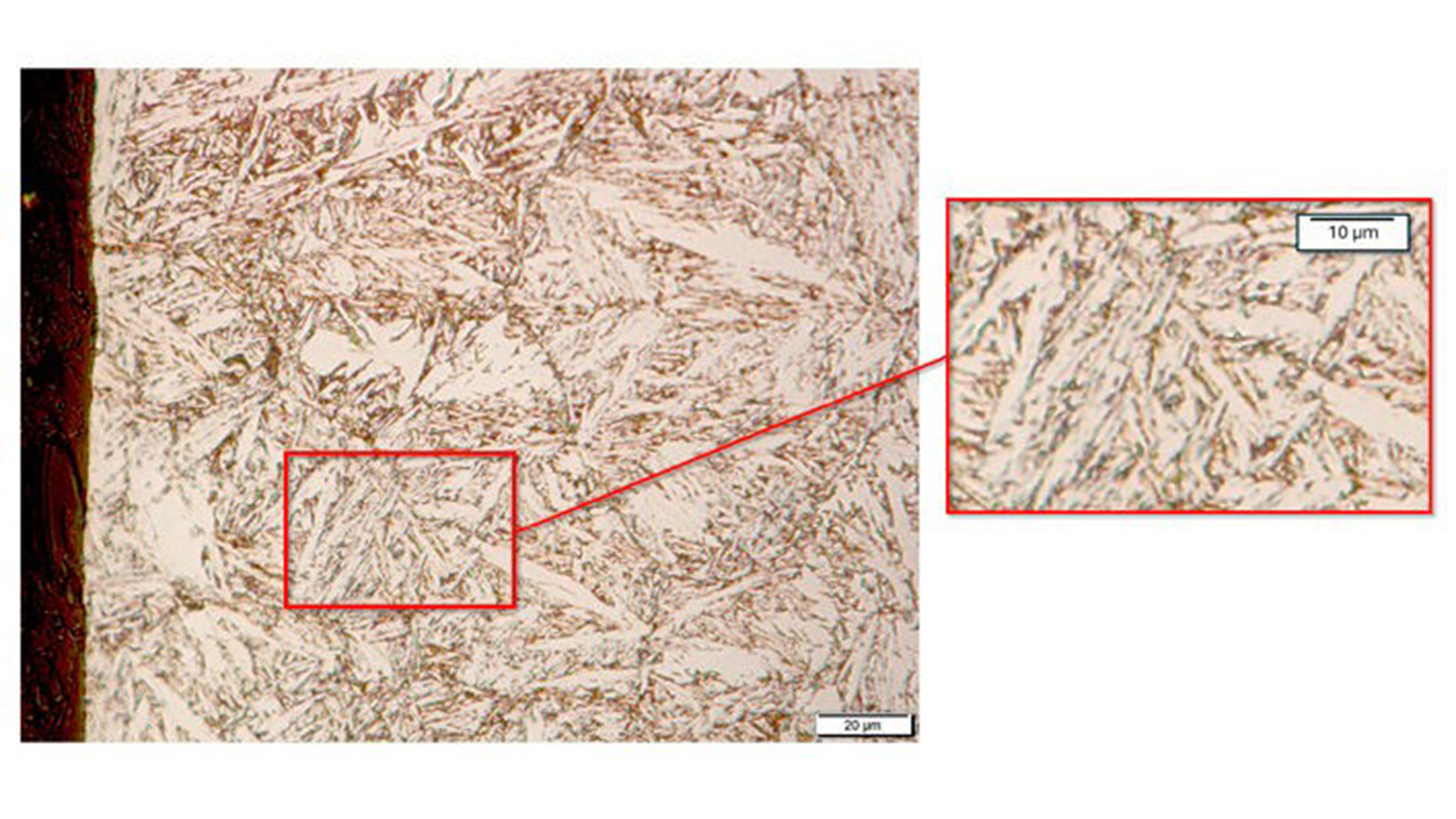

| The Role of In-Situ Techniques in Microstructure Optimization of Interstitially Alloyed Steels |

In-situ techniques such as thermogravimetry, differential thermal analysis, and dilatometry enable real-time monitoring of heat treatment, offering valuable insight into the thermal behavior of martensitic stainless steels. This is especially important for powder metal applications, including additive manufacturing with high-carbon steel powders like 440C, D2, H13, and T15. These methods support process optimization and material development by revealing key microstructural changes during treatment.

|

|

| New Standardization Projects |

The AGMA Technical Division Committees have been working on improvements and additions to our standardization efforts. We have three new projects to announce and are looking for technical experts from our membership to join the effort. These new projects, along with our existing projects—including AGMA 936-AXX, Calculated Bending Load Capacity and Pitting Resistance of Powder Metallurgy (PM), External Spur and Helical Gears—show great dedication from our technical community to continuously improving our knowledge and information for our industry.

|

|

| Extending the Life of your Heat Treat Equipment |

Reduce capital cost and extend the life of your heat treat equipment whether its high temperature furnaces, generators, tempers, etc. AFC-Holcroft can rebuild, update and modernize any manufacturer’s heat treat equipment. We have over 150 years of heat treat design, manufacturing and installation. Let us put our expertise to work for you!

|

|

|

| Surface Knows How To Lower Your Carbon Footprint |

Energy-Efficient Neutral Hardening Solutions

RX® neutral hardening eliminates carbon pickup enabling direct quenching with reduced cycle times, while DX® inert processing provides cost-effective protection without gases, both delivering energy savings. Calculate your sustainability savings with Surface atmosphere technology.

|

|

|

| Re-Control your Profile/Form Gear Grinder |

Machine Tool Builders can modernize and re-control your ‘Dinosaur’ Profile/Form grinder with new controls & drives. We include on-board dressing & and customized conversational programming at a fraction of the cost of new. Your place or ours, we’re ready to pick up wrenches. Call us today and let’s divide stock.

|

|

|

|

| Short Notice Auction, Closes July 22, Bid Now! |

Equipment No Longer needed in the continuing operations of Whiting Corporation, Monee, IL. Featuring – Gear Generators; Gear Hobbers; CNC VMC’s; Boring Mill's, CNC Plasma Cutting Table; CNC Tooling; Mills, Lathes; Keyseaters; Saws; Drills; Grinders; Sanders; Welders; Large Qty Welding Power Supplies; Welding Positioners; Forklifts; Tooling; Scrap Steel Plate & Offices.

|

|

|

| Four Bonus Reasons to Join an Emerging Technology Committee |

In today’s rapidly evolving manufacturing landscape, keeping up with emerging technologies isn’t optional; it’s essential. That’s why AGMA launched its Emerging Technology Committees eight years ago: to help member companies stay informed and future-ready.

|

|

|

| Kadia Develops Compact, Reliable Honing Machine |

With the third generation of its successful U line, Kadia introduces a state-of-the-art honing machine that redefines standards in precision, productivity and serviceability–while maintaining full versatility.

|

|

|

|